Introduction: Dust Collector Bucket Mod

This is a project completed at the Georgia Tech Invention Studio (IS) through funding from the Maker Grant. I'm an Aerospace Engineering student that works in the IS.

The IS wood room shop vacuums receive constant use and as a result the filters become clogged very quickly. I had seen a modification for a shop vac in Pennsylvania that was made from an oil barrel and PVC pipe that swirled the air to remove a lot of the larger wood dust particles before passing through the shop vac filter. The oil barrel was too large to be mobile enough for the wood shop and I wanted to improve the magnitude of swirl within the separation system. A 5 gallon bucket with a lid was the right size since it could be moved, emptied, and disassembled with ease.

The following instructions use the IS facilities. A CAM-WOOD WR-408 CNC Router is used to cut out the MDF pieces. These pieces can also be cut using a hand router with a circle jig and a table saw.

Step 1: Supplies List

All parts were purchased at Lowes. The total cost for supplies was around $100. The MDF was about a third of the cost.

- 3/4in Thick MDF

- 1.5in PVC Pipe

- 2x 5 Gallon Bucket

- 2x Removable Lids

- 2x 1.5in 90deg PVC Elbow

- 6x 1.5in PVC Coupling

- 9x 3/8-16 1.5in Hex Bolt

- 16x 3/8x1.5in Washers

- 8x 3/8in Hex Nut

- 1in Wood Screws

- 1-5/8in Wood Screws

- Loctite PL Premium

- 2in Shop Vac Couplings

- Worm Gear Clamps

I also used:

- PVC Primer

- PVC Cement

- Caulk Gun

- Miter Saw

- Power Drill

- CNC Router

Step 2: 3D Modeling of Inertial Separator

I used SolidWorks to model the MDF parts. With the HSMXpress addon, I created the G-Code that would control the CNC Router. The STL Files are attached, but the G-Code should be created using a post processor for the specific machine.

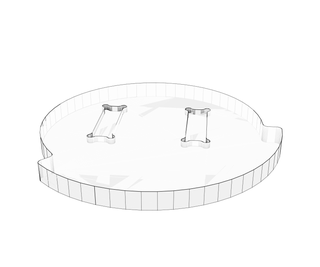

The top is a 9.5in circle with 4 thru holes for bolts and two 1.5in holes for the PCV. Easily made using a router with circle jig, hole saw, drill bit, and drill press.

The bottom is an 11in circle with a groove 135deg for the dust to fall through

Supports are 5in by 3in rectangles to hold the assembly together

Step 3: Cutting With CNC Router

I cut the MDF into 18x49in pieces so that it was easier to carry. The MDF was screwed into the CNC Router table and Mach3 was used to cut out the Separator parts. The supports can be cut out using a table saw and the top and bottom can be cut using a router with a circle jig.

Step 4: Lid Assembly

The top is glued to the lid with PL Premium and then bolted together to better distribute the weight. The supports are screwed and glued onto the top. Finally, the bottom is screwed and glued to the supports to create the swirl chamber.

Step 5: PVC Assembly

The PVC is cut to span the distance between the couplings and 90 Elbow. PVC is secured together with PVC cement and then securely attached to the bucket lid with PL Premium.

Step 6: Finished Project

Use shop vac couplings that can be purchased at any hardware store to attach a shop vac hose to the bucket. The shop vac is attached to the center and the inlet hose it attached to the outer PVC coupling.

The separator works great. To test it, I emptied out the dust from the shop vac and then vacuumed it up again using the bucket separator. All of the dust was in the bucket. Proof of concept.