Introduction: Recycled Turning Table With 3D-printed Parts

Right now at school we are learning different ways to scan things. We are using regular cameras instead of scanners so I thought that it would be easier with a rotating object instead of walking around.

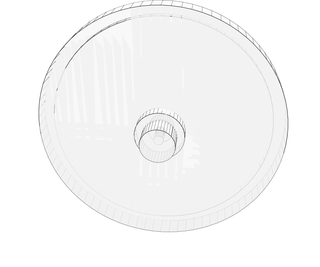

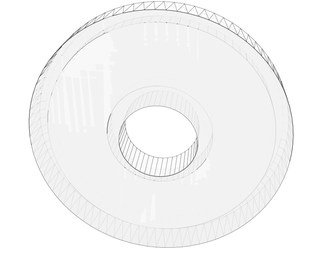

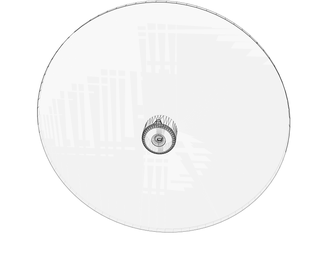

At the beginning of this project I just thought about designing an interface that would allow me to use the used filament rolls. The bigger plate that is conected to the motor came after a teacher asked for a motorized vesion. If you don´t have acces to a motor you don´t need to print the big plate. Just glue the lower part to a piece of wood and you would be able to finish in a couple of hours. (printing time)

Step 1: List of Materials

We print a lot so we have a lot of filement rolls over. I´ll been thinking about an idea that would allow me to reuse them.

Recycled parts:

- Nema stepper motor

- Bearing

- Filament roll

Tools:

- Sax

- Tape

3D-printed parts:

- Big table that work as interface for the motor.

Step 2: Asembling the Parts

I designed the parts with tight tolerances to avoid screws or other things. If you have a well calibrated printer it wouldn’t be a problem to get the right measures.

stl files at: http://www.thingiverse.com/thing:1970380

Step 3: Arduino

You don´t have to be an expert to be able to control a motor. i just used the sample files that are included in Arduino.

Wiring:

8: Blue

9: Red

10: Black

11: Green

Step 4: Take It to the Next Level

The table turns fine, just as I wanted. But if you want to be able to use both hands while taking pictures, adding a motor can make it possible. The table can perfectly work with a simpler motor, but I just have access to these motors at school so I used them.

Participated in the

Design Now: 3D Design Contest 2016