Introduction: Sharp Drive/Pinch Wheel for Type a Machines 2014 Series 1 Beta 3d Pinter

My beta drive wheel for my beta 3d printer was not sharp enough to drive the filament reliably, so I decided to take matters into my own hands, head down to the TechShop, and make a new one.

My hands were covered with grease most of the time, so I don't have too many photos, but here's how I did it.

All design files are available here in SVN. If you like, you can checkout all the files directly with SVN rather than downloading from here.

Materials Required

My hands were covered with grease most of the time, so I don't have too many photos, but here's how I did it.

All design files are available here in SVN. If you like, you can checkout all the files directly with SVN rather than downloading from here.

Materials Required

- 3/8 O1 Drill rod from Grainger. Chosen because it's easy to machine and easy to harden.

- Jet Lathe (any metal lathe should do)

- Mill used for hobbing. Could be done on the lathe too.

- Center drill

- Approximately 4-4.5mm drill

- 5mm end mill. (Could be a 5mm hone too)

- 6-32 tap

- M3 tap

- 3d printer, to print the hobbing rig.

- Lathe cutoff tool

- Propane torch

- Canola oil

- M3 tap

- propane torch

- little cup of oil

- magnet

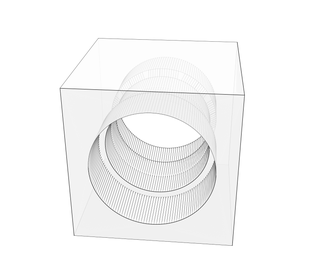

Step 1: 3d Print the Hobbing Rig. Then Make the Shaft

Hobbing is the process of using something like a tap called a hob. In fact, I'm using a tap for my hob :-)

Basically, you 3d print the hobbing jig. That's the easy part.

The harder part is making the shaft. I did that on the Jet Mill. Sorry no photos, but this was my first project on the lathe, and it wasn't that easy :-/

See attached STL and PDF for the parts you need to make.

Step 2: Make the Blanks on the Lathe

Here I use a 2.8mm cutoff wheel both to make the channel, and to cut off.

Tools used for this step:

Lathe setup

Tools used for this step:

- Jet Lathe

- center drill

- approx 4.5mm drill

- 5mm reamer or end mill

- Drill chuck

Lathe setup

- Mount a 2.8mm cutoff tool perpendicular to the workpiece in the tool holder

- mount the drill check in the tail stock

- clamp the 3/8 drill rod stock in the mill, with almost nothing protruding out the jaws

- Mount a center drill in the tailstock

- drill the center (about 900 RPM)

- mount a 4mm drill in the tailstock

- drill at least 15mm into the stock (900 RPM)

- reposition the stock so that about 20mm are protruding

- zero Z on the face of the stock. If using a 2.8mm cutoff tool, set the left face of the cutoff tool to the face of the stock, and set the DRO to -2.8mm.

- move to 3mm from the face and cut a groove down to 7.58mm using the cutoff tool.

- move to 11mm and cut the blank off all the way.

- Deburr the parts so that it'll fit on the 5mm shaft of the hobbing rig.

- Repeat until tired.

Attachments

Step 3: Hob the Parts

In this step we turn the blanks into pinch wheels!

Tools used:

Tools used:

- Mill

- Hobbing rig made in step 1

- 6-32 tap

- oil, cutting fluid, etc.

- Clamp hobbing rig into the mill's vise

- put drill chuck into mill

- mount 6-32 tap into the drill chuck

- set speed to about 1000 RPM

- put oil/lubricant on part & tap

- put the blank onto the hobbing shaft.

- turn on the lathe. MAKE SURE IT'S GOING THE RIGHT DIRECTION! Ensure that when the part moves into the tap, the tap will have a tendancy to push the part closer to the bearing. Otherwise the blank will simply be shoved off the shaft and you will almost certainly break your tap.

- slowly move the workpiece towards the tap. You just need to get the feel for this. Once my tap started hitting the base of the groove, I went about 15 thousanths farther.

- Let it run for a bit. Use lots of lubricant to wash chips away. I didn't, but should have.

Step 4: Drill and Tap for the Set Screw

Now we need to create the hole and tap it for the M3 set screw. Sorry no photos of this part.

Tools used:

Tools used:

- Mill

- parallels to hold the workpiece up near the top of the clamp

- small center drill

- 2.5mm drill or #39 drill

- M3 tap.

- leave the drill chuck mounted in the mill from step 3

- mount a blank in the clamp with your parallels. Line up the blank with the edge of the clamp.

- Align the center of the drill with the right place in the blank. See drawing for drill location.

- Clamp workpeice into clamp.

- Mount center drill

- center drill the hole

- mount the 2.5mm drill

- drill the rest of the hole

- Tap that hole with the M3 tap. Easiest if you leave the work piece in a clamp.

- Deburr the part using the hone or tap to create a nice 5mm ID hole again.

Step 5: Harden the Part

Now for some hot fun. Harden the part. This is why we chose O1 Drill rod. It will heat harden. Why harden the part you ask? Well, the original Type A pinch wheel was made from 304 stainless, and the PLA totally wore it down. I want to make sure this part will last the life of the machine, so I figured we'd harden it.

Tools required for this step:

It can be tempered after this by heating in a 500F oven for a half our or so.

Tools required for this step:

- Propane torch

- some canola oil in a tin can

- magnet

- Using the torch heat the part until it's red hot.

- Check to see if it's ready to be quenched by touching against the magnet. If it's still magnetic, keep heating it. Once it's not magnetic, dunk it in the oil.

It can be tempered after this by heating in a 500F oven for a half our or so.

Step 6: Done!

Now, you have a super pinch wheel. It should be sharp and last forever.

If you want, you can run this against a wire wheel to take off the black stuff and make it shiny again, but I just left it. It makes it easy to differentiate from my original pinch wheel.