Introduction: Sit Think Make Stool

Sit Think Make Stool

Every creative deserves a great place to...

...sit...

...think...

...MAKE!

A heavy duty workshop stool made from re-used rusty metal and blonde Maple timber...and some funky spray stencilling...

...follow along to make your own...

Step 1: Materials + Tools

MATERIALS

Some old rusty pipe...the diameter that you feel is right for your stool...three pieces needed to make a stool of height of around 540mm high

A slab of timber...or off cuts...I chose a blonde Maple as a contrast to the rusty metal...your choice should feel right to you. About 50mm thick.

Wood glue

Wood biscuits

M10 bolts x3 ... or threaded rod and nuts

5mm steel rod

Adhesive backed Vinyl for stencils

Spray can...colour of choice

Masking tape

TOOLS

Saw to cut metal - Hacksaw or angle grinder or a saw like the Evolution R185CCSL that I used

Saw to cut timber

General metal working tools...

...including Die + Tap for the 5mm rod

Welder

Angle grinder with cutting discs + abrasive discs

and/or Multi tool with cutting disc

Socket set or spanner

General woodworking tools...

...including expanding bit or Forstner bit the correct diameter of the metal legs

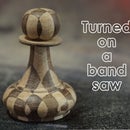

Lathe

Biscuit Jointer or similar

Clamps

Straight edges

Vinyl cutter or sharp knife

Step 2: WHY!

This project came about as Evolution Power Tools UK challenged me to make something cool with a new saw they had coming out...

...I am not sponsored by them, though I do get to keep the saw.

This Instructable will not be a sales pitch for the saw and where I use its unique ability to cut metal and timber at the same time I will try to give ideas of how the project can be achieved with the tools that you have to hand.

Saying that...the idea for the combination of metal and timber in the stool was inspired by a saw that can cut both materials...

...whatever tools you choose to make the stool with...you will have a great stool to use for years to come.

Step 3: LEGS

I chose to test out the hand power saw to cut the rusty pipe...

Safety first...you will need both hands on the saw so make sure the pipe is firmly cramped down.

Work out the length that you need...height of chair less timber seat thickness...plus 30mm socket into the seat...less say 40mm for the feet...the final measurement will depend on the height you want for your stool.

Cut three equal lengths.

Alternative tools for cutting -

Angle grinder with metal cutting disc

Metal bandsaw

A little patience with a hand hacksaw

Step 4: Clean Up the Rust

I wanted to keep the deep pitted rustiness of the old metal pipe, though I wanted to remove the surface red rust.

Gently remove with a wire wheel...I have mine mounted in my lathe though there are options for ones attached to drills.

Protect your eyes...Wear goggles!

Step 5: Prepare the Timber

Cut the timber for the seat to a manageable length and plane it nice and flat...either by hand or with a planner/thicknesser...

...I ended up with about 40mm finished thickness

Step 6: The Seat

As the stool has three legs...the seat shape is triangular.

To enable each side face of the seat to have nice planed sides, the seat is made up of three flat triangular pieces.

Set out the size of the seat that you would like...drawing full sized on a piece of paper is good to work this out...

...cut it into three equal bits!

Mark this onto the timber for the seat and cut out the three triangular pieces.

As you will notice the seat has blunt ends that makes for a pleasing and ergonomic shape and will allow for the leg fixing pin.

Step 7: Glue Up

My preferred method for gluing up timber is to use a biscuit jointer and timber biscuits...

Dowels...Dominos...and the like will work as well...or you could rely on a plain glue joint if you like.

Make sure the three pieces come together really nice and tight...some planning and or sanding may be required.

Cut your preferred joint...

...apply glue...

...knock together...

...and clamp.

I have no pictures of the clamping!...It was tricky due to no faces being perpendicular to each other...It just took a lot of clamps.

Step 8: Feet

As the pipe is a raw tube it needs some feet...

...to add continuity of materials I used the same Maple as I used for the seat.

Cut three blanks of Maple a little wider than the diameter of the pipe.

Turn the blanks down to the diameter of the metal pipe.

Reduce one end down to the internal diameter of the pipe to allow it to be socketed into the end of the pipe.

Add some Gorilla glue to the end and inside of the pipe...Gorilla glue is great for sticking metal to timber...It requires one surface to be wet with water for the glue to activate...

...Spritz the timber foot with water and gently tap the timber foot to seat tightly against the end of the metal pipe...

...leave to cure

Step 9: Sockets

The legs of the seat need to socket into the base of the timber seat at the pointy ends.

The ends will be trimmed off so allow outside of the sockets to be set about 20mm in from the finished cut.

Measure the diameter of the metal legs...mine were a none standard size for the forstner bits that I have...

...so I set my adjustable bit to the size that I need.

The idea is to have the legs splay out a little to give a larger and more stable base for the stool...mine was about 5 degrees off of vertical.

I made a simple ply template to allow me to drill the sockets into the bottom of the seat at the correct angle.

I drilled the sockets to about 30mm depth.

Step 10: Trim + Drill

Trim the pointy ends flat...THIS IS NOT THE FINAL CUT...it will be trimmed after the legs are pinned in place.

Drill a hole down into the leg socket...determine the size of the drill by the bolt size that you choose to use...

...the drill only wants to take out the solid core of the bolt for the leg pin...

...the bolt will want to bite into the timber

Step 11: Facet the Seat

I wanted the seat be faceted on the bottom to reflect the angle that the feet are spread out...

...mark out the amount to be planned off so that the feet will come perpendicular from the bottom of the seat...

...plane for all of three points of the seat.

It is also possible to do this step prior to cutting the sockets for the legs...and then cut the leg sockets square to the planned surface.

You will have a faceted bottom with a triangular flat shape in the middle...it will add a visual interest to the sides of the seat and make the seat feel visually lighter.

Plane the sides to a nice finish.

Step 12: Glue in the Legs

Again use the Gorilla glue in the sockets of the bottom of the seat...

...spritz the ends of the legs with the water activator...

...and place in the seat sockets and leave to cure.

Step 13: Pin the Legs

Weld a nut onto some threaded rod off cuts...!

...you really do not have to do this unless you want to use up some off cuts as I did...

...a threaded bolt will do the job well.

I used M10 threaded rod...and using the same drill used previously...drill through the holes and through the wall of the metal leg...

Screw the bolt into the hole, biting into the wood...continue through into the metal leg...

...the thread will tap itself into the metal...you will need to use brute force...a crude but effective technique.

Step 14: Brace

To stop the legs splaying out, we will need to tie the legs together.

Use 5mm diameter metal rod...

...Use a Die to cut a thread in the end...

...drill a suitable hole into the inside of each leg, half way up the leg...

...tap the holes...

...and screw the rods into place...

...this will give a really nice clean joint to the rusty metal legs.

Step 15: Tie It Together

The metal rods will come together in the middle of the stool...

...trim to length by hand or with a multi tool cutter...

...Weld the ends together and clean up with an abrasive disc.

Step 16: Cut Timber and Metal!

Cut the end of the metal pin flush with the end of the timber...

...as I was testing out the Evolution saw I was able cut in 10mm from the end right through the timber and metal in one cut...leaving a nice clean cut through both materials...

...alternatively carefully cut the pin with a hand hacksaw flush with the timber and use a metal file to clean up flush.

Step 17: Text

The words Sit Think Make encapsulate the creative process for me and I wanted to express it on my workshop stool...

...Make up some stencils from adhesive backed vinyl...

...I designed the text on Adobe Illustrator and cut out on my vinyl cutter...it makes life easy...

...don't worry if you don't have one...choose a nice blocky text like the one I used DDC Hardware, freely downloadable from the graphic designer Aaron Draplin...

...Set it to fit the sides of the seat and print out on paper...carefully cut out with a sharp knife.

Mask off all areas of the stool that you do not want to spray paint with masking tape and scrap paper...

...Stick the stencils onto the sides of the stool seat...or use spray mount with the paper stencils...

Spray the stencils with your colour of choice...

...straight away carefully peel away the stencils, making sure you don't touch the paint of the text, you don't want to smudge it!...

...remove the masking tape...

...stand back and admire your handy work!

Step 18: Finishing Touches

Mark around the feet and cut so it sits nicely on a flat surface...

...lightly sand the cut feet and the arriss's of the seat...

...apply Hardwax Oil to all of the wooden feet and seat...

...wipe on and buff off some Briwax to all of the metal parts to help stop the metal continuing to rust...

...FINISHED

All that is left to do is to...

...SIT...

....THINK...

...MAKE!

Step 19: Big Thanks for Making It to the End

Huge thanks if you have made it right to the end...

...there are a lot of steps though the project is really quite straight forward, in essence a three legged stool though with the added zing of a great mix of materials and some spray stencilling to cap it off.

If you think this project is worthy I am entering the Sit Think Make Stool into the Furniture Competition ...I would be delighted for your vote...

...BIG THANKS

Runner Up in the

Furniture Contest