Introduction: How to Build a Safe and Strong Baby Gate

Since I had built my Toddler Bed Guard out of PVC, I chose to do something similar for a baby gate. This would also apply nicely to someone who needs a pet gate.

This particular model is pretty simple and uses just PVC components to work. There are two ‘Slip Tees’ in the structure that allow the gate to slide vertically, just slightly so that you can lift it up and over the ‘Table Caps’ that it will snap into. Once over the Table Caps, just press down and it is as secure as can be.

Now, before you child-safety advocates turn on me, here are a few notes about this design:

- It’s made from furniture grade PVC and fittings, obtained from formufit.com, which is non-toxic, contains no dioxins (the nasty stuff they make plumbing PVC with), and is impact and UV-degrade proof (it won’t break down in sunlight).

- The slats are all 2-3/4” apart, which is BELOW the required 3” of distance between slates.

- It is extremely strong. I can put my entire weight on it (215 lb. male) closed and it will not budge.

- All corners and edges are rounded, so no snagging.

- There are no pinching mechanisms in the gate once closed.

- Finally, this is MY choice to make this for me and my family. If you detest such a project, dont make it.

I plan on augmenting this Instructable to make a baby-corral out of the same thing, but making legs that jut out from each side for stability. Look for that one soon.

Step 1: What You Need.

As I mentioned in the introduction, I used furniture grade PVC and fittings. First its safe (non-toxic) as it’s made from the same type of PVC used in kids toys, and second, it just looks much better. I built the prototype out of plumbing grade PVC and it looked ghastly. Bonus also is that furniture grade PVC parts have a few more ‘clever’ components to make it easier, such as the Slip Tees and Table Caps.

I ordered all my parts from Formufit (www.formufit.com) as they are the least expensive and have the best selection of parts.

Here are the parts I ordered:

- 12 x 1-1/4” PVC Tees

- 2 x 1-1/4” PVC 90 Degree Elbows

- 2 x 1-1/4” PVC Slip Tees

- 2 x 1-1/4” PVC Fitting Caster Inserts

- 4 x 1-1/4” Table Caps

- 2 x 1-1/4” Internal Domed End Caps

- 3 x 1-1/4” 5’ Furniture Grade PVC Pipe

I also had some spare 1-1/4” Plumbing Grade Pipe to make the connecting inserts, which are not exposed. Fairly inexpensive, a 10’ section will run you $3.00 at Home Depot or Lowes. They will cut it down for you if you need.

Hardware

You will need the following hardware to secure everything together:

- 2 x 1/4” x 2.5” or 3” long Hitch Pins (Ace Hardware)

- 1 bag 3/4” Wood Screws (Full Thread)

- 1 can of PVC Cement

Normally I would have used a Miter Saw to make all of the cuts, but I chose to use a hacksaw, as it was just as fast (a little de-burring was needed). I did need a ¼” drill bit to make holes for the ‘hitch pins’. Everything else is screwing, so just a power drill a couple of drill bits and a

- Phillips bit should get you through this.

- Power Drill or Power Screwdriver

- Philips Head Bit

- Hacksaw

- Measuring Tape

- 3/22” drill bit

- 1/4” drill bit

- Countersink Bit

- Knife or Deburring Tool

Step 2: Design

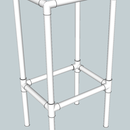

I designed the gate in Google SketchUp, using the PVC components available from Formufit here. I built it with a 32” doorway in mind, as that is what most of mine are.

In order to accommodate for larger doors, you will need to add another ‘T-Section’ (or more than one) for an additional 5 inches in width. An example is shown below in one of the SketchUp diagrams.

To accommodate for doors between 33” and 37” you can increase the parts that connect to the wall by an inch on each side, but do not go over 2” or you will make the span between the frame and the doorway more than a 3” gap, which is not recommended under ‘baby gate standards’.

I’ve made the Google SketchUp plans for the baby gate available here on the Google SketchUp 3D warehouse. Feel free to modify/customize them as you need.

Step 3: Cutting

One benefit of miter saw cuts over a hacksaw: deburring. You will need to debur each of the PVC segments using a pocket knife, razor blade, or if you have one, a deburring tool.

I’ve provided a cutting template for all of the lengths of furniture grade and plumbing grade PVC pipe below. I’ve tried to maximize usage, and it has worked out pretty good for me. Make each cut, as straight as possible for each piece

You’ll need a total of each of the following for the Furniture Grade PVC pipe:

- 5 x 30”

- 1 x 20”

- 4 x 2.5”

You’ll need a total of each of the following for the Plumbing Grade PVC pipe:

- 12 x 3"

Once the cuts are made, throw the parts into a box so they don’t roll away on you.

Step 4: Table Cap Modification

You will need to slightly modify two of the Table Caps to allow them to act as a ‘catch’ mechanism. I created the cut so that it just barely, but securely holds the door in place.

It’s a little difficult to explain the cut, and I will let the diagrams below do most of the work, but basically you make one horizontal cut right above where the top of the tab meets the cap and one vertical cut with a hacksaw along two of the supports of the Table Cap. This will remove a small crescent shaped section that you can throw out. You could also perform this with a Dremel tool, if you are so inclined.

TIP: When cutting the table cap, secure it with screws to a table or piece of lumber, to make it easier.

Once your cuts are made, sand down all sharp edges with sandpaper or a sanding block, to make the edges smooth. We don’t want any spikey edges!

Step 5: Assemble the Top

IMPORTANT: I chose to use 3/4” wood screws to keep the pipe and fittings in place. I drill a small hole into the fitting, where it meets the PVC and use a Phillips bit to put the screw into place. It is just as strong as PVC Cement, and the friction of the pipe into the fitting keeps it together anyway, and you can avoid the noxious odor and other concerns that come with PVC cement. Also, this way you can perform a ‘dry fit’ of all of these items and then attach screws or do it one at a time, your choice.

I like to use a countersink bit attached to the drill so that it makes a nice indentation for the screw head to go into. It keeps in clean and won’t allow snagging of clothing or little fingers.

I do use PVC cement for a couple of items later.

Should you choose to use PVC Cement, remember: PVC CEMENT ESSENTIALLY MELTS THE PVC TO MERGE THE PIPE AND FITTING TOGETHER, IN ABOUT 30 SECONDS, SO MAKE SURE THAT THE PARTS ARE LINED UP AND GOING IN THE RIGHT DIRECTION WHEN CONNECTING THEM.

We’ll start assembling the top of the gate. For this you will need two (2) 90 degree fittings, five (5) tees and 6 (six) pieces of the 3” plumbing grade PVC segments.

Simply assemble the fittings as shown in the diagram below, with a 90 elbow first, followed by the four tees using a 3” Plumbing Grade PVC segment between each fitting, then another 90 elbow. You’ll put another tee facing outward off of the final 90 degree fitting.

Step 6: Assemble the Bottom

Now for the bottom of the gate assembly: For this you will need seven (7) tees, and six (6) 3” plumbing grade PVC segments.

Assemble the fittings as shown in the diagram below, with a tee vertically positioned, and followed by four (4) tees facing upward, with another tee vertically positioned. Use the 3” plumbing grade PVC segments to connect them all together. Attach another tee vertically positioned facing outward to the top of the final tee.

Step 7: Insert Pipe Into the Bottom

In this step, we are going to add the vertical pipes to the top and bottom gate segments.

Insert the five (5) 30” segments of furniture grade PVC into the bottom section of the gate that we just assembled. Secure the pipes in place with screws. Insert the one (1) 20” segment of furniture grade PVC pipe into vertical tee that is off to one side.

Slip the two slip tees over the 30” segment of PVC pipe at the far end. This will be our hinge mechanism. We’ll get back to these later.

Step 8: Attach the Bottom to the Top

In this step we will start to put together the main gate by attaching the bottom segment with pipes inserted into the top.

Line up the top of the gate with the pipes already attached to the bottom of the gate and make sure they are all in place by pressing down hard on them. Then attach with screws to secure the whole deal.

Step 9: Make the Gate Removable

You will need two of the 2.5” furniture grade pipe segments, and a two table caps. We are going to drill 1/4” holes through both the table cap and pipe inserts. This will accept the hitch pins to make the gate removable.

Screw the table cap into a table or piece of lumber to secure it. Push the 2.5” furniture grade pipe segment into the table cap. It should be ‘slightly’ loose. Next, drill through the Table Cap and furniture grade pipe around 1/2” from the end of the table cap, through both sides.

Push in the hitch pin (it should be slightly difficult at first, as you have to get by the ball). It should go all the way through. You will see in my picture I used a 3.5” length hitch pin. I suggest a 2.5” or 3” at most.

Using the 3/4” screws on the outside of the Slip Tees (that are on the 30” pipe segment), secure the 2.5” segment of pipe to the Slip Tee. Do this for both Slip Tees.

Step 10: Add the Catch Mechanism

Using PVC Cement, lightly coat the inside of the remaining 2.5” furniture grade pipe segments and insert an internal end cap inside of it. Wipe away any excess PVC Cement that may come out. Then insert the other end (uncapped) end of the 2.5” furniture grade segments into the two outward facing tees on the gate structure. Attached with screws or PVC cement.

Step 11: Installation

IMPORTANT: When installing the gate, make sure that you are installing into a stud, door frame or other solid structure. Sheetrock alone will not hold up ANY baby gate. If you cannot install directly into a stud (when putting into sheetrock), use a nice piece of hardwood to span between the studs or wall.

Slip in the two Caster Fitting Inserts into the two tees on the bottom of the gate. These will act as feet. I recommend for hardwood floors to add a couple of felt pads available at most stores to make it easier on your floors.

Line up the Slip Tee/Table Cap combos with the wall or inside of the door that you want to install onto. Line up the Slip Tees with the with the Tees on the opposite side of the gate so that the whole thing looks symmetrical. This also allows free travel of the slip tees, which is part of the catch mechanism. Attach Table Caps to the doorframe, studs or wood structure with 2” wood screws.

Once attached, the gate should swing freely. Insert the two ‘modified’ Table Caps onto the ‘catch posts’ and line them up on the opposite wall or door frame. Make sure that the section that you cut out of the Table Caps faces UP. This is critical. You want them positioned so that the gate will snap into them. Screw these into the studs or door frame with 2” screws.

Enjoy!

Finalist in the

Humana Health Challenge

Participated in the

Craftsman Tools Contest