Introduction: Vertical Pallet Planter With Automatic Water Cycling. No Watering!

Step 1: Concrete Shoes for the Good Guys!

This step looks hard but it really isn't. If the plastic of the base of the bucket takes all the weight of the planter and moves, it will break and leak. So you need to make strong concrete round the base. In this case, I made the concrete using wet masonry sand as a sand mold and a flower pot that is a bit wider to make the hole in the mold., I used a pallet with plywood under the sand and then a 3 to 1 mix of coarse sand and cement for the concrete of the foot. So lots of pictures and a few image notes to explain the steps. The pictures are screenshots from a camera movie so not wonderful quality but its better than watching my youtube movies! As I write, they are curing, it is cold so it will be a while. BUT, I have already made one pallet planter to a slightly different pattern and that first one does not have the feet at all. I haven't used a sand mold in years but it works great. (Your sand has to be just the right firmness and wetness. If it sumps too easily you may have to add a portion of clay. (if you have clay!)

Step 2: Shoes Off!

Weather got really cold so shoes had to cure a bit longer. Anyway here is the shoos been taken out

Step 3: Pallets and Preperation

There are many types of pallets, Standard ones are about 4 ft by 4 ft. and up here in Victoria, many businesses are only too happy to get rid of them. 4 by 4 with decent solid 2 by 4's and one by sixes for the slats are ideal. I have a video about how to break them apart with a long breaker bar, a tier iron and a 2 by 4. This works great. I also made up a tool to break them up. That is in the second picture. It does a rougher job than the other method but it sure is quick! It is 2 old brick hammers, a twisted fence post holder, and a waste piece of hollow steel tubing. I wasted a lot of welding sticks but no metal! when I made it. (My welder is an entry level one and just too weak to do decent welds) but hey! $50 to $70 online + shipping I also cut a groove in the front of one of the brick hammers (with a cut off wheel on the angle grinder) and it pulls out nails easy! I am a stone mason and these were 2 hammers with broken handles. It is cool to use them again! The handle bar is hollow and light, It has a plastic cap on top that I never bothered to take off.

Step 4: Putting Humpty Pallet Back Together Again. Trial Run.

My first one was a trial because the pallets were none standard size and there was not enough room. Here is how it turned out.

Step 5: Bottoms of Planters All Lean Back

Water cycles through the system from top to bottom, To prevent it dripping on each plant as it goes down, the planter bottoms lean back. This means that water gets directed to the back and drips down the back of the planter all the way to the bottom. Everything gets watered but the plant leaves don't get splashed.

Step 6: Putting Humpty Together Again, for Real. (Having Learned From Experience?)

So, 4 by 4 pallets, with experience, Can I do it right?

Step 7: Airlift Pump, Non Standard, How Can I Make It Easy As Possible?

I was one of the main advocates for "the T-joint method" for airlifting water in windowfarms, but the t-joint works OUTSIDE the bucket of water and works best with 18 inches or more of "submergence" (this depends on your bubble pump specs). I tried it in the buckets but their max submergence is only about 14 inches, and no room for the U below! Can something be modified?

Step 8: Replacement for T-Joint. Lots of Testing on This Stage Before I Got It Right!

Low pressure airlift pumps are really simple, you buy a an aquarium bubble pump (most will pump air 2 ft deep in water) and then you connect the air into a 1/4 inch internal diameter tube at the bottom of the bucket. BUT, the air will often bubble out and not go up the tube at all. With the T-joint method, I put the airlift outside the bucket and put a loop of tubing down in a u shape to prevent backflow. How can we get the air entry as low as possible and still prevent back flow without the Utube?

I ended up making something really simple, I punched a hole in a WIDER TUBE that fits snugly over the 1/4 inch internal tube and then pushed the air tube into it . But you still get an awful lot of bubbling in the bucket! The solution was very simple. I connected a 10 inch section of 1/4 inch tube to the other end of the section of wide tube and stuck a piece of air delivery tube in the end of that.

It is hard to explain why this works. Imagine the inertia of that 10 inch tube of water. by the time it is moving, and squeezing throught the tiny end hole, the air is already going up the other tube and carrying water into the pallet planter,! next it starts moving the other way and inertia (again) keeps it moving. No bubbling, maximum submergence and really even delivery of water to the plants! This worked great!

Step 9: Pumping Water

Here is the water coming up to the top and bubbling out of a 1/4 inch internal tube At the moment I have a little hole into a pop bottle to stop water gushes and the water just drips into the top portion of the pallet planter. I am changing this so it drips onto some dolomite limestone first. This will help make the water less acid and will also add some calcium and magnesium ions to it. All good stuff!!!

I hope.

Step 10: Here Is the Ideal Design, Just the Legs to Go in the Boots Now! Coming Soon!

So here it is. The first one was a trial to make sure it works. Just have to put the concrete round the bottoms of buckets and it might be done by the end of this week! If you can imagine it being 2 of these sitting in 3 Buckets, that is what I am doing.

I had to play with the airlift longer than I expected to make sure it was reliable. I expect only one airlift tube up will be needed and the 2 (3 in my case) buckets will be joined with a tube too. I will probably have plastic sheet or some gutter pipe under the bottom most planter section.

Step 11: Best Tubing Sizes and Getting the Tubing Dirty.

I have done a fair bit of testing over the last couple of years (and back to 2002 with pulser pump demonstrations) and the best tubing sizes for this type of airlift pump seems to be 1/4 inch or 3/16 inch. In this case I use 1/4 inch internal diameter tubing. My battery operated air bubbler (that I used to demonstrate it on video) supplies enough air to easily run 2 of these things through 1/4 inch tubes.

But my little mains driven bubbler supplies less air and can just barely run 2 at a time. In that case the solution (if you want to run 2 planters) is to go down to 3/16 inch tubing. 3/16 is only 1/16 different from `1/4 inch in diameter but it isn't diameter that counts. It is area and 3/16 inch tubing has just over half the cross sectional area! 3/16 tubing is slower but it only requires half as much air as 1/4 inch tubing!

Getting the tubing dirty. New tubing will NOT work well for a day or 2. It might have a sheen or might be just too clean and water repellant. After a day of water going through it, it will work great. Total difference. What I do is just run it coiled around on the ground and going straight back into the bucket for about a day. That dirty s up the tubing nicely!

Step 12: Dilemma??? Air Tube From Far Away or Electricity Supply a Few Meters Away? Money Money Money!

It would be great to have the timer and little bubble pump in a shed right beside the greenhouse. It is about 60 ft from a plug to the shed. BUT $50 for cable, $50 to 80 for conduit and plugs brings things up over a hundred dollars and you still have to dig it in underground! so hundred dollars plus a lot of work! My bubble pump and timer are in another shed with a proper electrical supply to code but it is 120 ft away!

Low pressure air would never travel that far through$30 worth of 1/4 inch tubing, would it?

Step 13: The Little Pump That Could! and Success Breeds More Problems to Solve!

So, I laid down the 120 ft of plastic tube from the little shed to the greenhouse and started her up, Sure enough, it pumped the water, even at that distance! Saves $70 and a sore back from a day of digging! But now, how do I divide up the air so that it runs 3 or 4 pallet planters? Darn! Another problem.

Step 14: Which Details Do You Want Next? Comment to Let Me Know.

I can bring you details about cutting the wood, or more detail about taking out the nails from the pallets or finer points about placing the airlift tubing? or something else entirely.

I can even go in a slightly different direction based on a comment.

One point is that the water dripping through the system will take daytime heat and bring it down into the bucket. ( Water has a really high heat capacity) (might be useful in the greenhouse to protect from night frosts). I could measure that effect if asked.

Anyway, that is the deal. If you want some part explained in more detail, you have to ask.

I made the concrete bottoms today Thursday 9th January and have to let them set.

Thanks

Brian

Step 15: Conclusions? Conjecture? If You Build It, People Notice? Puny Pneumatic Power Grid?!

I thought and talked about this for years but never really had a good spot for it. The design stage was a bit harder than I expected but nothing too dramatic. Now we just have to see how it performs long term.

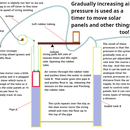

For me, the great thing that came out of it is the pneumatic power grid concept. Lots of people make cool alternative power thingys but they are usually too small to connect to the electricity grid. So they just give up! But this thing is just 1 psi. We should all be able to make a machine that makes 1 psi! And 1 psi can travel fair distances. We should be able to manage 2 or maybe 4 psi fairly easily. Well, with 4 psi, you could have a pneumatic power grid connected to your neighbours? If you have surplus, just let it go! It is only cents worth of energy but for things like watering plants it is super valuable. My "water pump" is just a 2.5 ft length of tube! in a throwaway plastic bucket! Anyway, take a look at the concept in the diagram and see what you think! Brian

Participated in the

Redneck Contest

Participated in the

Instructables Design Competition