Introduction: How to Use the Laser Cutter and or the Water Jet to Make a Radius Check Gauge for Organinc Sheet Metal Work (Metal Shaping, Panel Beating, Etc) I Made It at TechShop

How to use the Laser Cutter and or the Water Jet to make a Radius Check gauge for Organic Sheet metal work (Metal Shaping, Panel Beating, etc)

I made it at Techshop.

This is going to be a really short and simple one, but if you are doing any sheet metal forming, especially using the Planishing hammer this will allow you to make a really useful tool yourself.

You can get this tool online for $20ish in plastic and $40ish in anodized aluminum, but with this Instrucable and access to Techshop, or equivalent tools, you'll be able to make one yourself. As an added bonus it'll have a cool TechShop logo on it with extra Texas Flair

since I'm a member at the Austin Round Rock Texas location.

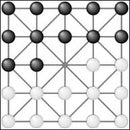

(The red image is of a commercially made radius check gauge, I'll upload pics of the real one soon)

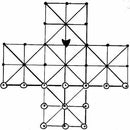

Step 1: What the Cut File Looks Like

Here is a gif of what the cut file looks like so you can visualize it better

Basically, you download the PDF I created here:

https://docs.google.com/file/d/0B8Bg9eVVQhaYOWJkNWlaYnpyNGs/edit?usp=sharing

Or get it from step 3 of this Instructable

The red lines are cut lines, the black lines are etch. Pretty standard stuff here no surprises.

I replaced the '0' that marks the perfectly flat side on the professional one with a ruler

as I thought it'd be alot more useful in checking profiles and everyone knows a ruler is straight without extra

hints.

Step 2: The Vector Pdf File

Here is the vector Pdf file in case you have trouble getting it from my Google drive link.

You may have to play with the cut line stroke thickness, as I did one in Inches and the other in Metric and then copied and pasted them into one file. This causes the lines to be differing thicknesses. Simply select all the red cut lines in Illustrator or Corel Draw, and change them to the thinnest stroke (i.e. hair line) before cutting.

Step 3: Making One Out of Acrylic

If you want to make one out of Acrylic, just go to the laser, Run the Etch pass, then run the cutting pass. You can do them all in one pass, but in my experience you have to run the cutting passes twice to get a clean unwarped cut in acrylic, so I suggest doing it separately.

Step 4: Making One Out of Aluminum or Anodized Aluminum

If you want it out of aluminum, you'll have to do the same thing, but on the Water Jet, I've taken the SBU, but I'm not sure about the settings, so grab a dream Consultant to get the cutting and etching set up.

If you want to make it out of anodized aluminum, it's a hair more complex. Take it to the laser first, carefully index it in the upper left hand corner of the laser cutter and run the etch pass only to etch through the colored anodized coating.

Then goto the water jet, do the bit where you set the corners of the piece of metal so it's auto indexed, set it to use the same corner you put in the 0,0 on the laser cutter as the 0,0 on the water jet, and run a cutting pass.

Step 5: Finished

If you do this properly you'll get a nice professional looking radius check gauge like they sell on the intertubes.

The image I used of the red tool is (obviously) from trick tools.com, if you want to buy it in plastic or metal, they are a good option.

I made it at Techshop... we'll I'm About to make it at Techshop, once I get mine cut out I'll add more Photos. I'm putting the Instructable up as at Techshop a bunch of folks were talking about buying these for sheet metal work, and making them is pretty easy now that the design is finished.(plus is has the Awesome Techshop Texas logo!)

I hope you enjoy it.

Did I say Techshop!

Techshop!

Beetlejuice!