Introduction: Make a TARDIS Model - 1/10th Scale

When I was looking for instructions to build a scale model of the TARDIS, it was a bit difficult for me to find consistent dimensions for the parts. I ended up finding plans for a full size TARDIS and calculated the sizes for a 1/10th scale model. It ended up being about a foot tall. The plans I was working from were in metric, so it was easy to adjust to 1/10th scale. In this instructable I'll be listing the pieces in both metric (mm) and imperial measurements (inches). If you do need to adjust the measurements to a different scale size, I recommend adjusting the metric measurements.

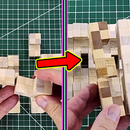

I made this instructable with a lot of steps and a lot of pictures, trying to give plenty of detail for the process. I've also tried to group the steps into sections to make it easier for you to come back and resume where you left off. And remember, it's very important to refer to the pictures that I have included in the steps!

I have also made some videos showing the process, and I'll have links to those through out this instructable where each video is relevant. I have also added those videos to a YouTube Playlist, and if you would like to view that playlist you can view that here: Make a TARDIS Model. Each section of this instructable will also have a list of tools and parts that I used for that section.

Step 1: Cutting the Wood - Tools and Parts

Step 2: Cutting the Wood

Here is the video for this section: Intro And The Base

I cut most of the parts from a thin sheet of plywood that I measured to be 3/16" (5 mm) thick. You can use a different thickness of wood and that should work out fine for the most part. But there are some parts that will need to have their measurements adjusted if you use a different thickness of wood. I will try to mention when this may be an issue.

I'll be cutting the wood with a razor blade, and I'm making most of my measurement marks with the razor blade. When scoring the wood at the measurements, lightly scratch the surface several times. Once a good score line is made, I used more pressure to finish cutting through the wood. When cutting your pieces, keep in mind which direction you want the wood grain to go for that piece. I also found that it works out much easier to cut the parts out in groups of pieces rather than each piece individually. After cutting the pieces I sanded all of the corners lightly.

Step 3: The Base - Tools and Parts

Step 4: The Base - Step 1 of 3

Here is the video for this section: Intro And The Base

From the plywood, cut out a 5 5/8" (148 mm) square. Also cut out 4 rectangles, each 6" (153 mm) long and 7/16" (11 mm) tall. NOTE: if the wood you're using for the rectangles is not 3/16" thick then the size of the square will need to adjusted. It needs to be 6" (153 mm) minus twice the thickness of the wood.

Next, lay out the pieces how then need to be glued together. For the 4 side panels, sand down the ends so that they connect to each other at a 45 degree angle. Once they all fit in place nicely they are ready to be glued together and to the square.

Step 5: The Base - Step 2 of 3

The sides of the TARDIS has square pillars at the corners, and for these I used 4 pieces of 1/2" (12 mm) square dowel that is 9 5/8" (245 mm) long. Once the glue is set from the previous step, cut out holes in the base for these 4 vertical pillars. Measure 1/4" (7 mm) in from each of the edges, then measure 3/4" (19 mm) in from the edges. The 4 squares that are made at the corners when making these marks are where you need to cut out for the pillars. If you're using a different size of pillar than what I used, you'll need to make an adjustment to the 1/4" (7 mm) mark that you make to compensate for the change. It's important to make sure the distance between each of the corner squares is 4 1/2" (115 mm) apart, later steps and parts are dependent on this measurement.

To cut out the holes for these pillars, drill out the bulk of them then file out the rest. As you make each hole it's a good idea to test fit the pillar.

Step 6: The Base - Step 3 of 3

Next, make a taper on the edges of the base. Mark all of the sides at 3/16" (4 mm) so that it's easy to see when you've sanded it down the correct amount. The taper needs to go from this mark and up to the 1/4" (7 mm) mark that was previously made on the top.

After sanding down the first taper take a look at it. Now sand down a taper on the other 3 sides. And that's about it for the base.

Step 7: The Sides - Tools and Parts

Tools:

Parts:

- Wood Sheet, 3/16" (5 mm) Thickness

- (or something close, some measurements will need to be adjusted)

Step 8: The Sides - Step 1 of 6

Here is the video for this section: The Sides

3 of the sides will be identical and the 4th will be the doors that open, but still using the same pieces so let's cut all of those at the same time.

- The top panel for each side is made from 2 pieces. One is 5" (126 mm) long and 7/8" (23 mm) tall, the other is 4 1/2" (115 mm) long and also 7/8" (23 mm) tall, let's cut out 4 of each.

- The middle piece is 8 1/4" (210 mm) long and 7/8" (23 mm) wide, we'll need 4 of these also.

- The sides pieces are 8 1/4" (210 mm) long and 5/16" (8 mm) wide, this time cut 8 of these, 2 for each side.

- Then there are the horizontal pieces that are 1 1/2" (38 mm) long and 5/16" (8 mm) tall, 10 for each side, so we'll need 40 total.

- All of these pieces will get glued to panels that are 9 3/16" (234 mm) tall and 4 1/2" (115 mm) wide, 4 of these panels are needed for the entire project.

There is one more piece that will be needed for each side, but I'll have that listed when it's needed.

Step 9: The Sides - Step 2 of 6

These are the steps for the first 3 sides.

Starting on the main panel, we need to make sure the middle piece is centered. Mark a line down the center of the panel and the center of the middle piece. Also extend this line down the ends of each piece too. This makes it easier to line things up as you're gluing them together. Now you can glue these together and clamp them down for the glue to set. Take care to get them aligned correctly, using the marks you made. After the clamps are in place and before the glue dries completely you can move the clamps around a bit to clean away the excess glue. This can be easily done with a damp cloth, just as long as the glue isn't dried yet.

Step 10: The Sides - Step 3 of 6

Next let's glue on the 10 horizontal pieces. Attach them evenly spaced on either side of the middle piece. Then before the glue dries on these pieces, attach the two side pieces at the ends of the horizontal pieces. You want to glue the side pieces on before the horizontal pieces dry just in case any of the horizontal pieces are the wrong length. This allows you to replace any of these pieces if you need to. Once these are all good, clamp everything down and let the glue dry.

Step 11: The Sides - Step 4 of 6

For the 2 pieces that make up the top panel, you want to mark the center on the top edge. This makes it easy to align them together and also align them to the main panel. Glue them together and to the main panel, making sure the shorter piece of the 2 gets glued directly to the main panel.

Step 12: The Sides - Step 5 of 6

With all of the other pieces for the side assembled and all the glue dried, there is one more piece to attach. This piece is 8 1/4" (210 mm) long and 5/16" (8 mm) wide and it will be glued to the center of the middle piece. Clamping this piece down was a little bit tricky with the clamps that I had. Getting the ends was easy, but my clamps couldn't properly reach the middle. My solution was to use other pieces as braces and put my clamps on those. Just don't glue these extra pieces down, they'll be removed after the glue dries.

Step 13: The Sides - Step 6 of 6

Next we need to fit the pillars to the side panels. You want the back of the side panel to be even with the back corner of the pillar. You will need to make a notch in the pillars to do this. Line one pillar up to the top piece and mark the pillar where it needs to be trimmed away on the front. To mark the side of the pillar flip the panel upside down and line it up to the back, then mark the side of the pillar. Finish by marking the piece that needs to be cut away, then cut out that piece.

Each pillar needs to be trimmed away on 2 sides. As you do this trimming test fit the pieces together to make sure everything is fitting correctly, making adjustments as necessary. Do this with all 4 pillars and the 3 sides. When I built mine, 2 of the pillars I glued to the back side, and the 2 pillars that I'm going to attach to the doors I left unglued. The left and right sides were not glued to any pillars.

Step 14: The Doors - Tools and Parts

Tools:

Parts:

- Wood Sheet, 3/16" (5 mm) Thickness

- (or something close, some measurements will need to be adjusted)

Step 15: The Doors - Step 1 of 5

Here is the video for this section: The Doors

Making the doors will be similar to the sides, but there are 2 pieces that need to be cut in half, the main panel and the first middle piece. After they are cut, glue the split middle pieces to the split main panel, then you can glue the horizontal pieces and the side pieces just as before. But the pieces for the top panel won't be glued to the door, and the last center piece will be glued on differently, and a bit later.

After the glue dries, I use a clamp to hold the doors together. This isn't to glue them together, but rather to hold them in alignment while working on the the other parts.

Step 16: The Doors - Step 2 of 5

This step is optional.

I decided to add magnets to help hold the doors closed. The ones I used are 3/8" in diameter, but other sizes would work too. Drill into the back of the doors near the top with a drill bit the same size as the magnets. Also drill into the shorter piece of the top panel where that piece lines up with the doors, then glue the magnets into the holes. This is a good time to glue the 2 pieces for the top panel together, but again, don't glue the panel to the doors. Let the glue dry completely before moving onto the next step.

Step 17: The Doors - Step 3 of 5

Next let's fit the pillars to the sides. Line up one pillar to the top piece and mark the pillar where it needs to be trimmed away. Follow the same process as previously. Do this for both of the pillars that you're using with the doors.

After trimming the 2 pillars that go on the side of the doors, test fit the pieces together. If it looks good, you're ready to connect the doors to the pillars with hinges. Align the top of one door with the pillar and mark where you want to mount the 2 hinges for that door. When I did this I made a mistake on the placement of the top hinge, I ended up lowering it later during the build because it was overlapping the window that I cut out later. Next, turn the parts over and screw the hinges to the pillar first, then screw the hinges to the door. Do this with both doors.

Now with the hinges in their correct place, you'll need to trim a notch into the pillar so that they are flush with the pillar instead of on the surface of the pillar. Mark around the hinges, remove them from the pillars, and trim out the notch. Once they are trimmed out enough, screw the hinge back into place.

Step 18: The Doors - Step 4 of 5

There needs to be a slight gap between the doors so that they don't rub when you open and close them. Sand them down a bit, making sure the doors will move smoothly and they open and close. The next thing to do is to hide that gap when the doors are closed.

Take the final center piece that was added to the sides [8 1/4" (210 mm) long and 5/16" (8 mm) wide]. This piece will only be glued to the left door, and only half of it is glued on. This will allow it to cover up the gap between the doors when they are closed.

Step 19: The Doors - Step 5 of 5

One last step for the doors. If you notice, at the top of the doors you can see the individual doors and you can see a space when they are open. This needs to be addressed, otherwise it will be noticeable when the TARDIS is complete.

Mark a line on the doors, just above the magnets. Then remove the doors from the pillars and cut those small sections off of the doors. Sand the rough edges a bit then reattach the doors to the pillars. When I did this, I cut a piece of wood that's 4 1/2" (115 mm) long and 5/16" (8 mm) tall. This piece can be a different height, but make sure it is this length. Glue that new piece across the top, leaving a gap over the doors. You can see that this piece I used sticks out above the very top. This is fine because after the glue completely dried I sanded it down to be flush with the top of the door panel.

Step 20: The Roof - Tools and Parts

Tools:

Parts:

- Wood Sheet, 3/16" (5 mm) Thickness

- (or something close, some measurements will need to be adjusted)

- 3/8" (or 10 mm) Square Dowel

- 16 Gauge Wire

Step 21: The Roof - Step 1 of 5

Here is the video for this section: The Roof

The roof is made from 4 triangle pieces. To make these pieces cut out a larger piece of wood that is 2 5/16" (59 mm) tall and about 11" (280 mm) long. This is longer than needed, but it will help to make sure you have a little extra to work with. The triangles need to end up around 4 9/16" (117 mm) along the long side and around 3 1/4" (83 mm) along each of the other 2 sides. To make the pieces use a square to mark a line 45 degrees from one side. Then from the other side mark another line at 45 degree to make the first triangle. Do this a few more times until you have 4 triangles marked. Then cut them out.

Cut 4 small pieces from a 3/8" (10 mm) square dowel. Mark them at 5/16" (8 mm) on each of the 4 sides. Then using a handheld saw cut the piece, a little bit at a time on each side to make sure to cut it straight. Next measure 5/16" (8 mm) in one of the other 2 directions and sand the piece down to that mark. When finished sanding this side it's final dimensions are 5/16" (8 mm) by 5/16" (8 mm) by 3/8" (10 mm).

The next pieces are 4 5/16" (110 mm) long and 5/16" (8 mm) tall.

Step 22: The Roof - Step 2 of 5

The last pieces are 4 9/16" (116 mm) long and 7/16" (11 mm) tall, these will be the first parts of the roof to be working with. Set them up on their sides as a square. Before gluing them together sand them down at the ends to a 45 degree angle. Once these pieces are sanded so that they fit together, glue them. Before the glue dried I used the grid on my work mat to help me get the corners square. After this part of the frame dries we will use it to help me make the roof.

Step 23: The Roof - Step 3 of 5

The triangles for the roof are supposed to be angled. To get the angle that's needed, use the square frame that you have just made to hold the pieces in place as the glue dries. Because the roof is angled the triangles need to be slightly less than 90 degrees at the point, so to get them to fit you'll need to sand them down a bit on 2 of the edges. Do this by setting 2 of the triangles in place and seeing where they need to be sanded down. Do this for each of the pieces, test fitting them together as you go until they fit together correctly.

Once they fit good, they need to be temporarily glued together. Put just a little bit of glue in the center and at a few other points. This little bit of glue isn't very strong, so you will need to add much more between each piece. Carefully break some of the glued points then clean away the dried glue. Then glue them back together with much more glue. When this re-glued seam sets break apart the other temporary joints and do the same.

When the glue dries, sand down the underside of the roof until it's about flat then check to make sure it sits flat on the frame. If needed you can also sand the frame to be flat and level too. Before gluing the roof to the frame I added wood filler into the seams on the underside of the roof, then sand it down once that dries.

Step 24: The Roof - Step 4 of 5

Now let's construct the other parts of the frame. The little blocks will be the corners, with the side pieces being glued to the 5/16" (8 mm) sides of the blocks. Line them up and glue them at the centers of the blocks. Check the picture to see how I marked the middles of the blocks. This helps to get them lined up with the side pieces, but the marks also serve another purpose. The other part of the frame fits within these marks, so cut a little notch out at these marks.

Now you can glue the different sections of the frame together, topping it off with the roof.

Step 25: The Roof - Step 5 of 5

This step is optional.

I didn't want to glue the roof to the rest of the TARDIS because I want to be able to take the TARDIS apart. If you want the roof permanently attached you can skip this step and glue the roof to the sides later on.

Using a 1/16" drill bit, I drilled a hole through each of the 4 corner blocks and into the lower pillars. I used a 1" long 16 gauge wire to hold them together. These are a snug fit and hold these parts together nicely while still allowing me to take them apart.

Step 26: The Light - Tools and Parts

Parts:

- Drill

- 1/16" Drill Bit

- 1/4" Brad Point Drill Bit

- 3/8" Brad Point Drill Bit

- 3/4" Hole Saw

- Handheld Saw

- Wood Glue

- Wood Filler

- Sand Paper

- Utility Knife

- Scissors

- Ruler

Parts:

- Wood Sheet - 3/16" (5 mm) Thickness

- (or something close, some measurements will need to be adjusted)

- 3/8" Vinyl Tubing

- Small Matches

Step 27: The Light - Step 1 of 3

Here is the video for this section: The Light

Using a 3/4" (20 mm) dowel, cut down one end of it so that I can fit it into a drill. Now sand the end of the dowel into a taper by spinning it with the drill on some sandpaper. Sand it down to a point, where the height of the taper is 5/16" (8 mm). This will be the cap of the light. Cut the cap off from the rest of the dowel. If any pieces chip off while cutting, you can use wood filler to recreate the shape.

This is optional, but I also cut a disk off the dowel that is 5/16" (8 mm) tall. I only used this disk as a reference piece for size.

Step 28: The Light - Step 2 of 3

For the base of the light, drill a 3/8" (10 mm) hole down the middle of the dowel. It may help to start with a 1/16" (1.5 mm) pilot hole. Go about an inch into this piece of dowel, then cut it at 3/4" (20 mm). File 4 notches around the central hole, these will be for the cap supports of the light. The 4 supports can be made from small match sticks or toothpicks.

For the "bulb" of the light use a section of 3/8" (10 mm) diameter clear tubing. The distance between the base of the light and the cap will need to be 9/16" (15 mm). Glue the cap and the supports in place here. When I cut the tubing to length, I wanted it to extend a little bit past the bottom of the lights base.

Step 29: The Light - Step 3 of 3

For mounting the light to the roof, there needs to be a hole in the roof to glue the light into. Started with a 1/16" (1.5 mm) pilot bit in the center of the roof. Next drill a 1/4" hole with a brad point bit. Now you can use a 3/4" (20 mm) hole saw that has a 1/4" center bit. Drill it from the outside going in because there will be some blowout, which you don't want on the outside but isn't a big deal if it's on the inside.

Now you can glue the light into place, making sure the base sticks out of the roof the same amount as the reference piece, if you made one. Also use wood filler to give the borders around the light a clean look, inside and out.

Step 30: The Windows - Tools and Parts

Step 31: The Windows - Step 1 of 3

Here is the video for this section: The Windows

For each of the sides cut out the top 2 sections for the windows.

Measure and mark the windows where the framing need to go. Put one mark on the sides, half way between the top and bottom of the window, then 2 marks equally between the left and right sides of the window. Extend those marks along the insides of the window, then onto the back of the panel.

Step 32: The Windows - Step 2 of 3

For the window frames use regular sized matches. For the horizontal piece use a full match with the top cut off. Align the match with the marks that you made, extending the marks as needed so that I can still see them as I hold the match in place. While holding the match here, use a utility knife to notch where you need to cut away to place the match. After cutting out the notches test fit the match, making sure the notches are deep enough. Also check the alignment from the front. If it's not aligned, adjust the notches. Once it is aligned glue the match into place.

For the vertical notches cut the top of the a match off then cut it in half. Hold one piece up against the edge of the first match then mark where the notch needs to be. Put some glue in the notch, and a bit of glue on the end of the match that will be up against the first match. Press the match into place then check the alignment from the front. A trick that I figured out to help with the alignment is using the grid of my work mat for reference. Each window frame has 1 horizontal piece and 4 vertical pieces, using 3 matches.

Step 33: The Windows - Step 3 of 3

For the "glass" in the windows you can use a thin piece of plastic, either clear, colored, tinted, whatever you prefer. Measured how big you want each piece to be then cut the plastic out. You can glue the plastic in place, but if you do then don't glue it until after you paint the TARDIS. I chose to use thumbtacks so that I can remove/replace them easily. The plastic I used was thick enough that I needed to drill 1/16" holes in it for the thumbtacks. If you choose to do this make sure you put the thumbtacks where the doors are the thickest.

Step 34: Final Touches - Tools and Parts

Step 35: Final Touches - Step 1 of 3

Here is the video for this section: Final Touches

Look over all of the parts that you made and touch-up any places that need wood filler. Once all of that's done, paint all of the parts, except for the plastic in the windows and the tubing in the roof. Each version of the TARDIS from the show is a different shade of blue so choose one that looks good and give it as much or little detail that you would like.

Step 36: Final Touches - Step 2 of 3

Now it's time to fully assemble all of the sections that you've created. Put the tubing in the roof/light, put the plastic in the windows, and if you want to fully glue the sections together, sand off any paint that is where you need to put glue. But if you want your TARDIS to be able to disassemble easily, you can use more of the 16 gauge wire to pin the sections together.

Step 37: Final Touches - Step 3 of 3

For the signs that go on the outside of the TARDIS, just like the shade of blue paint, there have been different designs for those also. I did a google search for TARDIS Signs and printed out the versions that I wanted and used Inkscape to resize them to match the size of my model.

To attach the signs you can glue them or use double sided tape, or whatever works good for you.

Step 38: And That's It!

And that's the model! It's not 100% complete though. I haven't made handles for the door yet, so if you have any advice on how to them, please leave a comment. And if you want to light up the light on the roof, you can put an LED into the tubing.

I would love to see your TARDIS model!

Social Media:

- Twitter - https://www.twitter.com/HowDoYouDIY

- Facebook - https://www.facebook.com/HowDoYouDIY

- Instagram - https://www.instagram.com/howdoyou.diy

Runner Up in the

Epilog X Contest