Introduction: Recycled Plastic Structure

As you may know, in Fablab Moscow we participate in the precious plastic project. We made the machines for plastic recycling and organise workshops where people can realise their ideas.

I made different injected objects (skate, bike pedals) but then I was looking for something universal, something that anyone need. So I thought about structures. Plastic is light, durable, shock proof. A plastic structure can be used as storage system, as table or chair basis.

In this instructables, I will show you different techniques that I explored to assemble injected plastic sticks: Injected plastic join, 3D printed join, welding.

Bonus: Ball pen out of recycled plastic tube.

Step 1: Inject the Parts

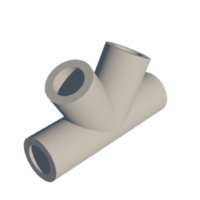

As shown in the video, the precious plastic injector has been used to make the parts. For the sticks, a simple aluminum tube has been used. For the joints, a three parts aluminum mould has been milled.

Step 2: Assembly

For this crane type structure, the joins are 3D printed. Milling moulds is expensive and time consuming so as a first prototype, I used 3D printing.

The vertical stick length are 74mm and the oblique ones are 162mm. The stick diameter is 7.4mm.

Step 3: Welding

Another convenient assembly method is welding. The main advantage is you don't need any join, you just hold the part in place. A hot air gun has been used to melt both sides then the parts are pressed together.

Step 4: The Pen

A mould has been made to inject pens. The process is not industrial fast but it is always a joy to handcraft your own pen.