Introduction: Tiered Mug Storage & Display

If you are looking for a complex instructable with lots of steps and parts, keep looking. This is a simple one, and one with instant gratification!

We've always dreamed of having a coffee mug display in our kitchen and we finally created one after buying our first home! Through this instructable, I will share the (simple) methods I used to design a tiered hook system that works with pretty much any mug, how I (simply) produced the hooks, and then how I installed (with minimal effort) the hooks into our kitchen cabinet with a glass door!

In our kitchen, we have a large built in cabinet that I have turned into the mug storage / display, but this same system would work with upper cabinets, or wall cabinets of pretty much any size, as well as being mounted under cabinets rather than within.

Supplies

To create these hooks, I used the following resources and supplies:

- Assorted Coffee Mugs

- Onshape CAD Program

- LulzBot 3D Printer

- PolyMaker PolyTerra PLA Filament

- 3/4" Self-Tapping Pocket Screws

- 1/2" wood trim (optional)

- Brad Nails & Nailer (optional)

- Cordless Drill Driver

- Carpenter's Square

- Tape Measure

Step 1: The Design

I first positioned the mugs in the cabinet and held them to see how many I could fit, as well as how many rows I could fit if they were staggered, or tiered. In my cabinet, I could fit two rows and four columns, so I started by designing hooks that would be two lengths to create the tiered effect. Even though I only used two lengths, I created a third and included it in this instructable incase a reader needed it for their own storage display.

From my mock positioning with multiple mugs, I could see that the second row had to be at least 5" longer to allow for the bottom mugs to be visible under the first row. Additionally, I could see that anything more than 7" would look a bit silly and obviously expose the hanger system, something I was trying to avoid.

With the hook lengths drafted, I moved to designing the actual hook that the handle would rest on. All of my mugs are random with different size handles, some were close in size while others were huge on a decorative designs. I spent quite a bit of time making cardboard hooks to see how the handle rested, as well as how the mug hung from the handle to make sure I was getting the desired effect. In the end, I created a hook with a radius of a little over 0.5" to accommodate the variety in handles.

With the cardboard prototypes and initial measurements taken, it was time to design the actual hook in CAD software so it could be manufactured. To do this, I used the Onshape CAD program which is free for public use and students / teachers. I am a big fan of Onshape for is collaborative features, device compatibility, and powerful features. If your interested in learning more about it, check out this instructable I put together comparing free CAD programs or my collection of Onshape Tutorial videos on my youtube channel.

To hang the handles, I created a flat top with two holes, one in front and one behind the hook, that would be used to fix the hooks with self-tapping screws. To aid in installation, the front hole extends farther past the shortest hook so the bit driver will be able to access the screw with ease. After adding this top, the hook began to resemble a J.

Lastly, I had to determine the depth, or thickness, or width, of the hook. From my cardboard experimenting, it seemed like all of my mugs could easily accommodate 0.5" so that is what I extruded the hooks to. Additionally, I determined that 0.5" would be enough material for a solid design, as well as printing in this orientation would allow the mugs to hang against the layer extrusion direction which would also strengthen the design.

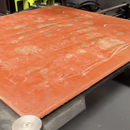

Step 2: Production

To manufacture my hooks, I used my LulzBot TAZ SideKick 747 3D printer and Polymaker's PolyTerra PLA filament. I am a huge fan of LulzBot printers as I have them both in my classroom and shop at home. Overall, I find them incredibly capable and durable, as well as easy to tweak and tune. I discuss LulzBot, as well as other FDM printers and ways to modify / tune your own in this instructable if you're interested.

Additionally, I like PolyMaker's new (at the time of writing this) PolyTerra Filament. It has a different texture when compared to PolyLite or other PLA filaments, as well as a matte finish. Its also recycled, so thats a bonus, and only $19 per 1kg spool (when writing this).

I sliced my models using Cura LulzBot Edition to have a layer height of 0.25mm and a fill density of 40%. Through some initial prototyping, I found this combination to be a good compromise between strength and speed. Printing at an even higher fill density wouldn't necessarily add much more strength as the mugs are hanging against the print extrusions, so some infill adds in rigidity. Additionally, I didn't want the hooks to be too heavy or prone to warping, something that would have been more likely with a greater density.

Top tip, if you want to place models closer together in Cura LE or the normal Cura, you can disable "ensure models are kept apart" in the general preferences window so you can nest and pack your designs closer and optimize your print space!

Step 3: Installation

Before installing the hooks, there are a few things I did to make the end result more aesthetically pleasing, as well as installation to be easier.

First, I cut and nailed in 1/2" white wood trim at the front underside of my cabinet shelves. This trim will be in front of the hook mounting points which will hide the tops / screws from view. This isn't necessary, especially if your shelves line up with window panes, but I thought it would add a more visually pleasing result to have the matte black hooks appear to drop from nowhere, or for the mugs to almost appear like they are floating.

Next I used a tape measure to measure out my two rows and four columns evenly, as well as a carpenter's squre to ensure the front row was inline with the back row. As the mugs are all different sizes, I wasn't worried about the mugs looking askew, but instead worried about the hooks looking staggered or uneven.

With lines sketched on the underside of my cabinet, I used a 6" square bit and 3/4" self tapping Kreg screws to install. As the front hole was placed well in front of the hook, installation was a breeze. The self-tapping screws are a must to avoid needing pilot holes as well as ensure you do not crack the shelves. No need to over tighten as that could crack your printed hooks. I used a torque driver to ensure each screw was evenly torqued and to prevent over tightening.

Step 4: Enjoy!

Once the hooks were in, it was time to hang the mugs and enjoy! I think the end result came out great and with minimal effort too. Before designing these "J" hooks, I considered, and played with existing hooks, but I'm glad I ended up fabricating my own.

Not only are the hooks spaced in such a way that the cabinet is filled and looks great, but its also super functional and easy to get the mugs in and out...something that is a non-negotiable in this house.

I hope you found this quick and simple intractable helpful, as well as enjoyed the tips and resources I shared. Thanks for reading and happy making!

Participated in the

Home Improvement Contest