Introduction: Eclips3D Quick Start Guide

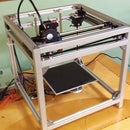

This is a guide to get started on your new Eclips3D. You must have completed the entire assembly of the Eclips3D as direction in the assembly Instructables before proceeding here. For more information on the build as well as all the open-sourced files so that you may build one yourself, visit the main Instructables page here:

https://www.instructables.com/id/Eclips3D-High-Prec...

Please, please please please follow all the steps very closely. If you skip a step or do something wrong you may damage your printer, and the damage will be on you to fix.

Note that I am not liable for any damaged inflicted upon you or your property caused by this printer. This printer is sold as a kit, and therefore improper assembly can result in these damages. Please take safety precautions when operating with high temperatures and electrical currents.

This guide is still a work in progress. Please use caution as not all aspects are completed yet!

Step 1: Preparing Software

First things first, lets get all of the programs and files you will need to successfully run your Eclips3D Printer. You may substitute alternatives for some programs if you know what you're doing and you prefer something else.

Azteeg Drivers (Only required for Windows users that are not on Windows 10)

http://smoothieware.org/windows-drivers

Eclips3D Firmware/Slic3r download (from latest version on my website)

http://www.eclips3d.com/docs.html

Repetier Host (Or other 3d printer slicing/communication software)

http://www.repetier.com/downloads/

Now that you have all the files you need, you can begin preparing them. If needed, run the first file you downloaded if you are using a Windows machine to install the drivers. Wait until that is done then close the window.

Next, put your microsd card into your computer. Take the firmware.bin and config.txt file (from Eclips3D Firmware download) and move them onto your sd card. Now eject the sd card from your computer and insert it into your Azteeg, but do not connect it to the computer yet. Don't worry, we will connect it in the next step :)

Install Repetier host. After that, you may leave it for now. Don't start the program just yet. We will come back in a few steps once we are ready to get the printer moving.

Step 2: Preparing the Azteeg X5 Mini Board

Azteeg X5 Mini Spec Sheet:

http://files.panucatt.com/datasheets/x5mini_wiring...

Good news! This step is pretty simple. Simply follow the pictures or the pdf spec sheet and you will be fine.

First, you want to make sure this "power" jumper is using the external power supply rather than USB power. If you don't switch this, you won't be able to print from the sd card and the board will only have power when plugged in via the usb cable!

Next you will install the microstepping jumpers if you haven't yet done so. The way it is configured is so that the x and y motors will run at 1/32 microstepping (max), and the z and e motors will run at 1/16 stepping for increased torque. If you prefer different setups, you may do so but you will have to adjust steps/mm in your config.txt file to accommodate.

Finally, you will want to install the heatshrink strip over your stepper drivers. Simply peel off the backing on the sticky side, then place it across the 4 stepper drivers.

After this, you're ready to use your Azteeg board. Check one more time just to make sure all of the cables are inserted fully and in their proper places and then you may proceed to the next step.

Step 3: Powering Up the Azteeg X5

The moment has come. Grab your usb cable and plug the board into your computer. OH NO IT ISN'T WORKING. Don't fret, we changed the power input for the board remember? Simply plug in your power supply and turn the switch on and viola, your board should light up. Lights will flicker for a bit but it is important that you end up with 4 solid led's lit. If you don't, you did something wrong. Read through the previous steps and make sure you did everything correctly. Also be sure your wiring is correct from the initial assembly and that you aren't mixing up your positive and negative leads.

Now you may open up Repetier Host. Some dialog boxes from Slic3r should pop up asking for more info. Here is what you will put in these boxes:

G-Code Flavor - RepRap

Bed Size - 200 (x) by 195 (y)

Nozzle Diameter - 0.4 mm

Filament Diameter - 1.75 mm

Extrusion Temperature - 210

Bed Temperature - 60

Now comes the fun part (not really)...configuring Repetier Host!

Step 4: Configuring Repetier Host

There are a few settings you will have to change in Repetier host to get your Eclips3D running right. Simply follow the pictures in order and make sure all of your settings match those in the pictures. Note that if you are running a newer version of Repetier than I had at this time, some settings may look different or have moved.

To start off, the first picture shows how to access printer settings. Also, be sure easy mode is off. It is off when the button is red, as seen in my picture.

Configure your settings to mirror mine. The last 2 tabs are not touched. Don't deviate from I have unless you know what you're doing!

Step 5: First Steps (OH BOY OH BOY!)

Yes yes it is finally that time. Perhaps the most exciting time of the entire 3D printer build. And also the most stressful if something goes wrong. So, before you continue make sure you followed all the previous steps word for word. If you have, you shouldn't have any problems. If not, I sure hope you know what you're doing!

Lets make it move! Make sure your PSU is plugged into the wall and the sd card is in your Azteeg. Flip the power switch to power up the board, make sure all 4 lights come on. Now plug the board into your computer. Go into Repetier host and hit "connect" in the upper left corner. The button should turn green and now say "disconnect." If it did, you're good. If not, double check your printer settings in Repetier. Now lets make it move....

On the right hand side, click on the "Manual Control" tab. Now make sure your printhead and print bed are near the middle of their travel, you don't want them to accidentally hit the ends! Hold your breath and press the right arrow for the x axis to move the printhead 10mm. You should see the printhead move very slightly to the right then stop. At this point you may hear some faint whining noises, that is normal when the stepper motors are powered up.

Test out the y and z axis, making sure the printer moves in the positive and negative directions for all 3. Then, press the button below the control panel which de-powers the steppers (see picture). As long as your printer successfully moved in all 3 directions you are good to go. If the axes were wrong or something doesn't work, don't worry as this will be fixed next!

Step 6: Correcting Axis Directions

If your motors aren't running in the proper directions (which is likely) you will have to muck about a little in order to get everything moving the correct way. For the Eclips3D, your min position (0,0,0) should be in the front left of the printer with the bed all the way up. X axis will move left to right, and Y axis will move forward and back. Z axis will move up and down

To reverse the motors, if directed below, do so by either unplugging and flipping the plug or reversing motor in config text file on sd card. Go through each statement in order and follow the correction directions if necessary!

IF.....

X and Y axis are flipped (ex telling it to move x actually moves y and vice versa): Reverse one motor (x or y, doesn't matter for now)

X axis is inverted (positive movements go to the left, negative to right): Reverse both motors

Y axis is inverted (positive goes forward, negative goes away and backwards): Flip x and y motor plugs, but DO NOT REVERSE EITHER

Z axis is inverted (positive goes up, negative goes down): Reverse z axis motor

After doing these steps, your printer should be moving in the proper directions! Do a quick test to make sure all directions are correct and you're good to go!

Step 7: Endstops and Travel Limits

Now it is time to make sure your endstops are working. First make sure they are plugged in to the board and plugged in the correct orientation (they will NOT work if reversed). Red goes to positive, green/yellow goes to signal, black goes to ground. Depending on where you purchased the endstops, you may need to pull out and re-arrange these wires to comply with the board.

Next, with the printer powered off, move your printhead by hand and ensure that it triggers both endstops before reaching the end of its travel (you should hear a little click). You want there to be about 1mm of travel left after it triggers the endstop. Ensure this is the case for the x and the y axis.

For the z axis, first make sure the bolts holding on the bed are tightened down so the springs are as compressed as possible. Now, manually raise the z axis until you hear it click. There should still be a few mm between the printhead and the bed. If so, you're all set to continue.

Turn on the printer and press all of the endstops with your finger. As long as the light on each endstop illuminated when triggered and nothing strange happened, you should be ready to test homing your printer. Manually move your print head to somewhere near the middle of the printer and move the z axis down so it is out of the way. Issue the following 3 commands, one at a time, in the manual control tab. Ensure each works before continuing to the next.

G28 X (homes x axis, printhead should move left towards min)

G28 Y (homes y axis, printhead should move back towards max)

G1 Y0 (moves printhead to position Y=0, aka y min)

G28 (homes z axis, platform should move up)

Hopefully you didn't just break your printer! If your printer stopped when triggering the endstop then did one "bounce" that means everything is working properly. Time to break in the z axis and test motion!

Step 8: Breaking in the Eclips3D

Well sort of, this will break in the mechanics side, not the hot end side. Don't worry, it's super easy! Simply grab the files below. Then in repetier go to the preview tab. Then click the icon that says load. Load up the first script you just downloaded. You should see a G28 command then followed by a bunch of G1 commands. Now grab a beer and hit run, but stay with the printer as it completes these! Your printer will automatically do a bunch of moves to test and break in the axes. The first file only does the x and y axis.

If at any time you hear the printer skipping steps (it sounds exactly as you would expect it to), immediately stop the program. Try to move the parts by hand and if you just noticed it was a rough spot you can try running the program again. If it happens repeatedly, stop and determine if the problem before proceeding. Common causes are too much pre-load tension on the x axis or misalignment.

After the program finishes, repeat the same process with the second file you downloaded. This one is only for the z axis. Before running the program, manually move the z axis to its home position. The reason for this is because by default in the Eclips3D firmware, the z axis homes at a relatively fast speed. Before it is broken in, this may be too fast for it! If the Z axis skips steps during the last motion, this is ok as it is an extreme test and likely will never be moving this fast!

After successfully running both programs, you can home all the axes and you're good to go!

Step 9: Testing the Hot End

Before beginning this step, ensure your E3D V6 hot end is fully assembled and ensure that the fan to cool the hot end is in place and connected to power. Check the thermistor temperature located at the bottom of Repetier host and ensure it is within a reasonable range for room temperature (around 20*C). If it is, you should be good to try heating it up. There is a possibility of thermal runaway if any electronics arrived damaged, so keep a close eye on your printer during this step. In manual control, set the extruder temperature to 200*C and closely watch the temperature on the thermostat. It may go over the set temperature by as much as 20*C, but that is ok for now. If you see it getting up over 230*C immediately power off the printer and inspect the board and hot end for damage or lose connections.

Now, assuming your hot end made it up to temperature, you can try extruding just a little bit of filament by hand. Grab your PLA filament (if testing abs, heat it up to 230*C). With one hand and with the other press down on the lever on the extruder. Now guide the filament into the top of the hot end and push it through until you start to see some plastic come out of the bottom. After you send a few inches through you can pull the filament back out the top and store it for now. The reason for this is because when you do an auto-tune of the hot end, you want it to be exactly how it will be when you're printing, so you want there to be some plastic already in the hot end. Once you're done, turn off the hot end and let it start cooling down, then proceed to the next step.

Step 10: PID Autotune

After your hot end heats up, you may notice the temperature oscillates around the set temperature but never settles. A little overshoot or undershoot when heating up is normal, but after one or two bounces it should level out. If your hot end does not, you may need to do a PID autotune.

To do so, start with your hot end at room temperature. Make sure it is raised up from the bed as it will be heating up. Issue the command "M303 E0 S210 C8"

Your printer will now heat up and do a few cycles. After a few minutes, it will complete and spit out a few numbers to you in the text window. These are your new Kp, Ki, and Kd values. Power off your printer and take out the sd card, then open up the config file on your computer. Scroll down until you find where these values are stored and update them with the new values generated from the autotune. Then save and eject your sd card and put it back in your printer. Try heating again and see if it levels out. If it still does not level out after doing this, remove your sd card and edit the config file once again with your computer. Cut the Kp value in half, then eject and put it back in your printer .This should help give you a more damped and steady output!

Step 11: 3D Printing Workflow

Ready?! I'm ready! I bet you're ready too! So lets get printing!

Not so fast.....first lets go over exactly how you print something. This is especially important if you want to..you know..print something.

First, make or get your STL model. You can download one off of thingiverse or design one in a 3d modeling program. If you design your own, just make sure you export it as a .stl file and make sure the units are correct. If they aren't, you'll notice as soon as you import it!

Next, open up repetier host. On the right hand side, hit the plus button. Then import your .stl file. You can move it around, resize it, duplicate it, etc. Once you have it in the right place, you're ready to slice it up.

Go to the slicing tab on the right. Make sure all the profiles are the ones you want selected, and that the print settings are how you want them. Normal prints are around 10 to 30% infill and the most common infill types are rectangular and hexagonal. I prefer hexagonal as it prints a much stronger infill, although it takes a little bit longer to do.

Then, make sure the print bed is clear of any old prints or dust and hit the print button in Reptier! Your printer should begin printing! If anything goes wrong during the print, you have the option to pause and cancel your print right next to where you started it on the top toolbar!

Step 12: Troubleshooting Hardware

Lots can go wrong as 3D printers are still a very young hobby technology! Hopefully your problem is simple, but who knows! Here are some frequent problems and solutions. If you don't see your problem here, head over to the forums. There you will be able to look for the solution there or ask it yourself!

http://eclips3d.proboards.com/board/4/troubleshoot...

Azteeg Board isn't recognized by computer

-Install board drivers

-Check it is being powered by PSU

-Ensure firmware and config file are on SD card and in board

X or Y axis gets jammed

-Loosen back belt clamp, wiggle gantry a little to re-situate, and re-tighten clamp.

-Loosen adjustable Y axis rod blocks and re-situate to allow smoother travel

-Ensure both X and Y motors are plugged in and being powered

-Ensure X and Y belt pulleys are tightened against motor shaft

Step 13: Troubleshooting 3D Prints

Well you made it this far so congrats! Just one more big roadblock before you are free to print whatever your heart desires. There are lots of things that can affect quality of 3D prints, and many guides out there already, so below will be 3 excellent and well written guides to correct print quality issues. The guides are (in my opinion) in order with the best/most comprehensive first.

https://www.simplify3d.com/support/print-quality-t...