Introduction: Pulser Pump Model. a Substitute for Lots of Fossil Fuel?

http://www.appropedia.org/ Pulser_pump is being used by students from Queens University in Toronto for a project on the pulser pump. It will be completed on 1st May 2010 Their initial results support most of what I have reported. They have included pdf files from various other research projects too. Worth a look.

Brian (18th April 2010)

Every second thousands and thousands of gallons of low grade water power runs to waste (low grade is water falling less than 2 meters). some of this water power was used for a thousand years to grind grain or pump for irrigation and other uses too. With cheap fossil fuels as a substitute, it is no longer economical to use this power. (interest on machinery and construction costs is greater than the price of the electricity produced per year).

Pulser pumps are a significantly cheaper and low tech way of using low grade water power so some of this power can be used competitively again!

This is a pulser pump instructable. You can find pulser pump info on utube and in a yahoo group.

Pulser pumps are so mind bogglingly simple that I am the only person who has ever put pulser pump info online.

No peer review= no credibility.

Please check and make a model or make a full scale pump.

YOU can make the differerence!

Step 1: Online Checking

You will find info in the yahoo group pulserpump and in utube and the internet glossary of pumps. Pulser pumps have been on the internet for 7 years.

I do not know of anybody who has made one even though the info is freely available. I do not know the parameters because I only made about 4 pumps on a tiny seasonal stream. 0.5 meters head and 500 liters per minute max flow.

TINY!

Pulser pumps might work better with larger head and flow. This is likely.

But if nobody ever trys, nobody will ever know!

Making a model and putting it online is the first step to acceptence.

Will you do it?

Step 2: Procedeure and Materials

This is materials list and procedeure to make a model

Materials list for the pulser pump model

These are the exact list that I used for a previous model.

You can substitute your own local equivalent as necessary

Measurements are in feet (') and inches(")

(I can put in the metric equivalent if needed.

An 8 ft long piece of 2"by 4" timber

A 22 inch long piece of 2"by 4" timber

A 30 inch long piece of 2"by 4" timber

A 35 in long piece of 3/4" internal diameter (1 inch external diameter) clear vinyl pipe A 79 in long piece of 3/4" internal diameter (1 inch external diameter) clear vinyl pipe

A 58 in long piece of 3/8" internal diameter clear vinyl pipe

22 3 and a half inch screws (screwed side by side, these hold the pipes in place against the wood)

A 1 and a half inch screw (holds the top cranberry juice container in place.

About 7 3 and a half inch nails to nail the 2 by 4 planks together.

Orville redenbackers hot air popping corn container (850g) 7 inches long

Ocean spray cranberry juice container (1 liter)

TOOLS

Drill, 3.5 mm drill bit (for pilot holes for screws and nails)

1 inch forstner drill bit. (This did a good job cutting the holes in the plastic bottles and lids.

PROCEDURE

Nail the 22 inch 2 by 4 to the 8ft 2 by 4 starting 10 inches from the bottom

Leave a 7 1/2 inch gap and nail the 30 inch 2 by 4 above that.

Carefully cut a 1 inch hole in the bottom of the Orville redenbackers hot air popping corn container using the forstner drill bit and using a piece of wooden handle in the container so it does'nt.t collapse.

Fit the shorter piece of 1 inch pipe into it and push it through about 1 inch.

Cut, drill or burn a hole (slightly smaller than the external diameter of the 3/8 inch pipe) in the bottom of the Orville redenbackers hot air popping corn container.

Use the forstner bit to cut 1 inch holes in the lids of both containers.

Cut 2 1 inch holes in the side of the cranberry juice container (at 90 degrees to each other). near the bottom.

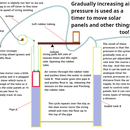

Join the pipes into the containers as shown in the diagram. Use the short screw through one of the holes to secure the cranberry juice container to the 2 by 4 behind it.

Use the 3 1/2 inch screws (or nails) (BESIDE not through the pipes!) to secure the pipes against the wood

Secure your model vertically against a wall, put a garden hose in, turn on and adjust the water flow and your model should work!

NOTES You can use 2 Orville redenbackers hot air popping corn containers (and no cranberry container) if you like. I had only one.

You can substitute a 58 inch length of 6 mm tube for the 3/8 inch tube if you like.

I did not have any and 6 mm probably works a little better.

Happy modeling

Step 3: Another Model If You Want to Try This Way!

Here is another model, This one is of a split process pulser pump.

Split process is seperate trompe and airlift pumps.

I found split process to be more efficient in my prototype. (the one that is shown on utube).

this model used acrylic for the chambers.

I found the other model more easy to make but depends on your skills