Introduction: Living Mushroom Sculpture

Mushroom are traditionally farmed on hardwood logs by inoculating them with mycelium.

These logs are usually stacked like in the image below. After a few months, the mycelium colonizes the log and mushrooms start to bloom out of it.

I was inspired by this process and wanted to make a sculptural gift out of it.

I wanted my sculpture to be able to hang in or outdoors and have minimal maintenance requirements.

In this Instructable you will learn the following things:

- How to inoculate and prepare logs for growing mushrooms

- Model quasicrystals in processing

- Create toolpaths in MeshCAM to machine these patterns

Supplies

For this project you will need to start with the following materials:

- Mycelium plugs of your choice, I used these.

- Some beeswax, or any other natural wax.

- Linseed oil to seal and protect the wood from the elements.

- I used a 1/8 in 2 flute endmill to do the machinig.

- Any non aromatic hardwood, I chose birch.

- Some high quality plywood.

Choose a plywood that has alternating colors, this way after the machining the grain patterns will be extra fun!

Step 1: Designing Quasicrystal Patterns for the Back Plate

For the backplate design I chose to use QuasiCrstal patterns.

Here is a Gif made by Keegan

I find these forms incredibly fascinating!

If you're interested in reading more about how to make these forms using code I suggest reading his blog.

Processing was used to make this code, I have slightly modified Rotormind's code to better suit my need.

He has a great Instructable on 3D printing quasicrystals if you're interested!

I have highlighted in red the part of the code to change to get different patterns.

I chose the values: 4,7,3

I have attached some other variations.

Attachments

Step 2: Converting the Pattern to 3D and Creating the Toolpaths

Now we need to convert the black and white pattern to 3D and then generate the toolpaths for machining.

I used MeshCam,( they have a 15 Day fully functioning trial if you want to try it out) to convert the image to 3D.

Open the chosen image, and make sure to select the right dimensions.

For the plywood I had, 0.15 Inches as the z depth worked well to bring out the stripy patterns in the wood.

Click Ok and meshCam automatically converts the image to 3D.

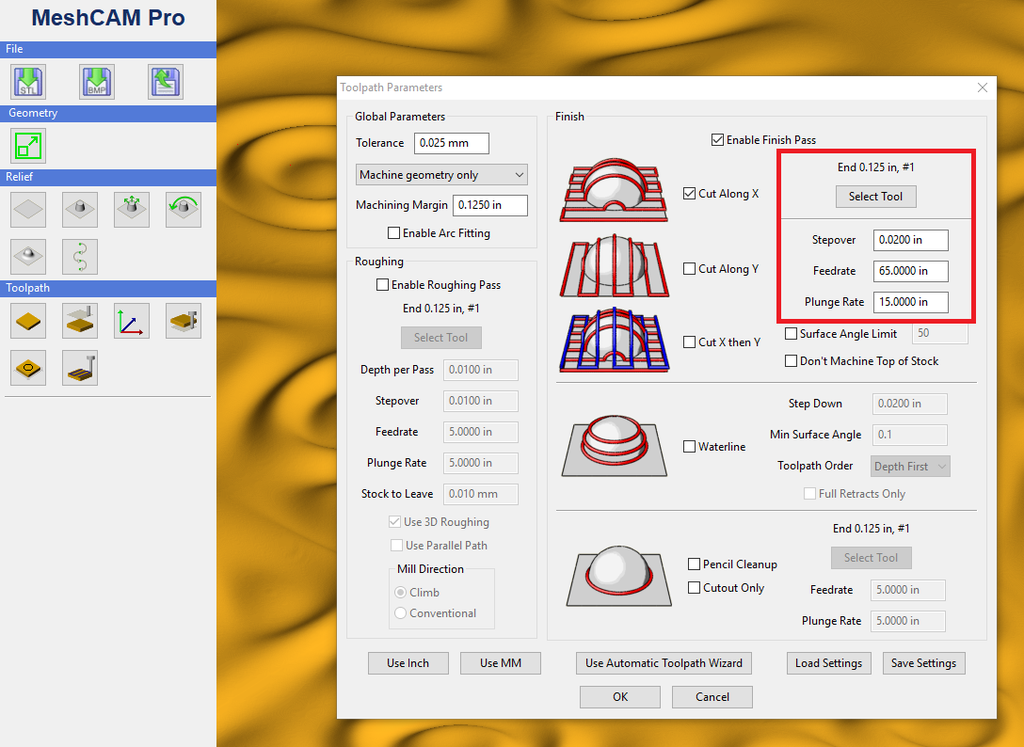

Next we need to make the toolpaths, for this I used the defaults setting for everything except the feeds and speed highlighted in the image:

I used a 1/8 Inch 2 fluted endmill. Select the right tool depending on what you have.

Note that I did not do a roughing pass as this is a very shallow form and so I directly did the finishing pass.

Click Ok and meshCAM will generate the toolpath.

Next click Save Toolpath and make sure to set the Save type as Basic Gcode-Inch if you are using an Xcarve to do the machining as highlighted in the images below.

Now we have our toolpath, open it in Easel so that we can send the Gcode to the Xcarve CNC machine.

Under the Import tab click on the Gcode import button:

Examine the simulation to make sure everything looks good before clicking on carve and sending the code the the machine!

And we're finally ready to machine the pattern!

Step 3: CNC Cutting the Patterns

Make a few test cuts first to ensure you like the outcome, also try out different stains and oils to see what it will look like when completed before committing to do the full cut.

After this secure your material firmly to the Bed and make the Cut!

Make sure to pause the carving and to vacuum out all the saw dust every now and then.

Step 4: Inoculating the Logs

While waiting for the CNC to complete the cut, in this step we are going to prepare our logs and inoculate them with mycelium.

Get freshly cut logs, they must be clean and not already have rot or other fungi growing on them as this will inhibit our mycelium from being able to colonize the log.

Any type of non aromatic hardwood will do but Oak wood is preferred, I chose Birch because that was what I had available to me.

Cut the logs to size as per your design and then drill holes in them at about 1 inch spacing.

\\

\\

After this insert the mycelium plugs in the holes, if they are bonded together like in the image below you can separate them without harming the mycelium easily.

\

\

Hammer them into the holes gently until they are flush with the bark.

Now we need to seal this log in Beeswax to protect the log from other organisms and to keep the logs moist.

Use a double bath to melt the beeswax.

Use a brush and coat the wax on the logs, make sure you cover it completely to fully protect it.

Step 5: Sanding and Finishing.

Now that the X-carve has completed carving our pattern we need to sand away the burrs and toolmarks:

I used 120 Grit sand paper for this, it was effective at quickly sanding out all the burrs.

I quite liked the tool marks and so i decided to leave those be.

A process shot of the left side sanded.

After sanding we now need to apply some linseed oil to protect the plywood for outdoor use.

To do this I used a foam brush and applied 2 coats and let it absorb into the wood overnight.

The oil also helped bring out the grain to exaggerate the stripy patterns in the plywood.

Step 6: Final Assembly and Notes.

Now that everything is ready, complete the final assembly.

Your mushroom sculpture is now complete! You can either install the sculpture indoors or outdoors in a lightly shaded area.

In 3 months the mycelium will colonize the logs. At this point mushrooms will start to sprout!

If after 4 months your mushrooms have not yet sprouted, you can water the logs with cold water, which will trick them into thinking it is winter. They will sprout soon after.

You can harvest and eat these mushrooms.

You can repeat this process every 3 months about 3 times with the initial logs.

Enjoy your mushrooms!

Participated in the

Gardening Contest