Introduction: 3D-Printed Beyblade-Style Propeller Launcher

Hi, I'm an eighth-grader at Lincoln Middle School in Santa Monica, CA.

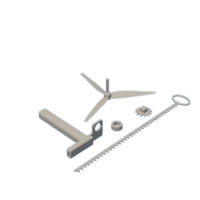

What it does; when you pull on a rack, it turns a pinion, which spins a propeller.

If you want to get straight to making it, you can skip the Introduction.

The Process:

Originally, I designed a system that used rubber bands to rotate the propeller. Ultimately, I found the rubber bands didn’t generate enough energy for the propeller to take off.

So, I reconfigured the design to use the force of your arm to turn a propeller through a rack and pinion mechanism. The new model is similar to a Beyblade, but in this case, instead of moving a Beyblade, it spins a propeller.

The Design:

To design the launcher, I first divided all the parts I needed into components in Fusion 360. The components are the Pinion (gear), Rack (straight gear), Propeller, Base, and Pinion Collar.

Pinion - I used the spur gear plug-in (which is SO useful) and made sure to have a small number of teeth so there would be less torque, and more speed. I also added an extrusion slightly larger than the square hole so it would act as a shaft and a gear.

Propeller - I used multiple sketches lofted together to make the blades and then added a circular pattern. I used 3 blades to generate more lift.

Rack - To design this, I took the empty space between the teeth of the Pinion and put it on a linear rectangular pattern. It didn't work as well as I wanted it to, so I tweaked the rectangular pattern parameters until I made a Rack I was happy with. In addition, I added a little slot for my finger.

Base - I used the method that almost always holds true; make a sketch, extrude it, make more sketches, extrude them until you’re happy with it. Then, add fillets. One note I have is that after I designed it, it was a little awkward to hold, so I added a handle which fixed the problem.

Pinion Collar - Designing the Pinion Collar was arguably the most difficult part. I wanted it to friction fit with the Pinion so, it could be pushed in, but not taken out. It took quite a bit of scaling, printing, and repeating, until the tolerances worked. You have no idea how many slightly-off Pinion Collars I have lying around! Though in this case, FDM printers worked to my advantage because the subtle layer lines help lock it in place.

Supplies

3D Printer

Yup, that’s it.

Step 1: Printing

- If you don't want to individually put each file into the slicer, you can just print the All Files file.

- Put the attached STL file(s) into a slicer in their original orientation.

- Make sure to include supports on the Propeller.

- Make sure not to put supports on anything else.

- The unit that the files are in is millimeters.

- If your printer isn’t big enough to print the Rack, you can cut out some of its length in the slicer.

- I used PLA on an FDM printer but other filaments (or resin if you use an SLA printer) should work as well.

Step 2: Assembly

After they finished printing,

- Remove the supports off the Propeller. (If the supports don’t come off easily, then reprint the Propeller File.

- Put the Pinion in the hole on the opposite side of the handle.

- Put the Pinion Collar on the opposite side of the Pinion. Push it in as far as possible while still keeping very little rotational friction. (If you find that the Pinion cannot move easily, then push up on the teeth of the Pinion to loosen it.

- Put the Propeller into the Pinion.

- Slide the Rack into the Base starting at the Pinion side.

Step 3: Making It Fly

For best results, I found that you should…

- Hold the Rack from the bottom. (See picture)

- Pull straight back as hard as you can!

Thanks for getting this far, and hopefully, you decided to make it. I found that this is great for the park or a little gift for friends.

Participated in the

Make it Fly Student Design Challenge