Introduction: Robotic Gear Arm Could Be Used for 3d Printing

The goal I wanted to give the robot

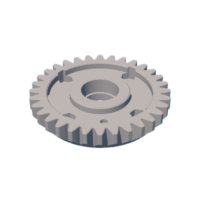

It is to make a model and demonstrate the force of its force transfer system through gears and with this also generate touch.

Ball bearings are used to reduce friction and make the robot move more harmoniously. The robot is designed to have a low center of mass.

A tx source was tapped to provide a 12v and 5v power supply for the motors and plate respectively

Step 1: hardware

The control system uses an Arduino Mega with a RAMPS 1.4 board and A4988 drivers. I provide a solid and functional programming foundation for the Arduino, which handles the interpolation of the stepper motors, performing all the geometric calculations, and smooth accelerations. It can handle some kind of serial GCODE communication.

Step 2: Turntable

Turntable

It has a bearing so that the stepper motor can be actuated and the flexibility of the arm can be controlled as a step.

The fully extended robot arm at the top multiplies every gear and bearing tolerance it has.

Step 3:

It is this part of genera and carries mechanical energy

It is composed of the impreza parts (h, locks), bolts, stepper motors and gears.

Step 4: Acoplamiento De Motores

It is this part of genera and carries mechanical energy

It is composed of the impreza parts (h, locks), bolts, stepper motors and gears.

Step 5: Base With Roller Bearing Gives Degrees of Freedom of Rotation

Step 6: Mechanical System Name

for arm (coupling of bearings preferably to place them using a press, I use a small press against a table they are not very expensive in hardware stores these 3 or 5 dollars)

Step 7: Motor and Electronics

Nema 17 motors of 0.6 were used, which gives you the precision unlike servos, an Arduino mega and a 1.4 ramp with its 4988 driver to control the motors and a tx source you can take out of an old computer and bridge the cable green with a black one so that the source turns on every time you feed it with AC

Step 8: Body

Step 9: Piezas Stl

here is all the stl so you can print it on your 3d printer

Attachments

base.stl

base.stl base_w_hole.stl

base_w_hole.stl baseRing.stl

baseRing.stl control_bottom.stl

control_bottom.stl control_top.stl

control_top.stl doc3.pdf

doc3.pdf GearBig_0.01mmTolerance.stl

GearBig_0.01mmTolerance.stl GearBig_0.05mmTolerance.stl

GearBig_0.05mmTolerance.stl GearBig_0.10mmTolerance.stl

GearBig_0.10mmTolerance.stl GearBig_0.15mmTolerance.stl

GearBig_0.15mmTolerance.stl GearBig_0.20mmTolerance.stl

GearBig_0.20mmTolerance.stl GearRotate_0.01mmTolerance.stl

GearRotate_0.01mmTolerance.stl GearRotate_0.05mmTolerance.stl

GearRotate_0.05mmTolerance.stl GearRotate_-0.05mmTolerance.stl

GearRotate_-0.05mmTolerance.stl GearRotate_0.10mmTolerance.stl

GearRotate_0.10mmTolerance.stl GearRotate_-0.10mmTolerance.stl

GearRotate_-0.10mmTolerance.stl GearRotate_0.15mmTolerance.stl

GearRotate_0.15mmTolerance.stl GearRotate_-0.15mmTolerance.stl

GearRotate_-0.15mmTolerance.stl GearRotate_0.20mmTolerance.stl

GearRotate_0.20mmTolerance.stl GearRotate_-0.20mmTolerance.stl

GearRotate_-0.20mmTolerance.stl GearSmall.stl

GearSmall.stl gripperBase.stl

gripperBase.stl gripperFinger.stl

gripperFinger.stl gripperHolePlate.stl

gripperHolePlate.stl leg_30mm.stl

leg_30mm.stl leg_35mm.stl

leg_35mm.stl leg_40mm.stl

leg_40mm.stl leg_45mm.stl

leg_45mm.stl leg_50mm.stl

leg_50mm.stl lever.stl

lever.stl lowerShank.stl

lowerShank.stl manipulator.stl

manipulator.stl pleuel.stl

pleuel.stl pleuel_bend.stl

pleuel_bend.stl robotGeometry.pdf

robotGeometry.pdf socket.stl

socket.stl socket_clearanceWoSetScrew.stl

socket_clearanceWoSetScrew.stl stabilizer.stl

stabilizer.stl stabilizer_endstop.stl

stabilizer_endstop.stl step.zip

step.zip triplate.stl

triplate.stl upperShank.stl

upperShank.stl

Step 10: Codigo

code

Step 11:

Step 12:

Step 13:

Participated in the

Metal Contest