Introduction: CompFab Computer Milling 2D Grid

For this assignment, we were supposed to recreate one of the designs we made for the 3D printer (additive fabrication) with a computer-aided milling tool (subtractive fabrication). I decided to use the 2D grid I made as my very first 3D printer model, since it seemed like it would be easy to translate into CAM commands.

Supplies

Fusion 360

An existing STL model

Step 1: Preparing the Model

I started by loading the STL of the original 2D grid into Fusion 360. It imported as a mesh, which I then converted to a BREP solid body, but the resulting body had a lot of tiny facets all over (as shown in the first two pictures) I was worried that the number of edges might throw off the contours for the pocket geometries when milling later on, so I spent a good amount of time merging the facets into large faces so that the body looked exactly like the original model I had created for the 3D printer (shown in the third picture).

Later on, when I was trying to add the milling operations, I ran into a lot of errors where I would get tool collisions in cutting out any of the pockets. I realized the model was way too small for the milling tool to be able to cut out many of the shapes, even with the smallest bit, so I scaled up the model by 5 times. This way, all of the gaps that needed to be cut out would be plenty large enough that I wouldn’t encounter any collisions.

Step 2: Adding the Milling Operations

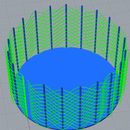

In the Manufacture workspace, I created a setup each for the top and bottom faces I would need to cut the grid out of. Since I wouldn’t be able to use an actual CAM machine, and so I wouldn’t need to create a stock that corresponded to a piece of physical material, I started by using the default stock size, which is sized to the model with a little bit of excess in each direction. The first image shows this stock, though this was before I merged the facets into large faces. The second image shows the coordinates for the top setup- the bottom setup was identical but with the z-axis flipped.

I faced the top surface and then used the 2D Adaptive Clearing operation to roughly cut out all of the largest shapes. Then I followed up with the 2D Pocket operation to clean up the edges and cut out the smallest triangles. Finally, I added one more adaptive clearing operation to remove the top layer of material around the perimeter of the grid. This left me with the shape mostly cut out on one side, and a completely flat surface on the other side. It was important that I leave the entire bottom plane intact, rather than just cut the grid perimeter out directly from the top plane with a contour operation, because if this was a physical object then it would need to have something to clamp on to when I flip the material to mill out the other side.

For the other side, I needed to cut out the remaining material in each pocket and trim the perimeter material off completely in order to finish the object. I used a combination of adaptive milling and pock operations to finish clearing out all of the shapes in the grid, then used another adaptive milling operation to clear most of the remaining excess material around the outside of the shape. Finally, I added a contour operation to clean up the outside edge all the way through the stock material. The third screenshot shows the structure of both setups and all their operations.

Step 3: Simulating the Entire Process

I ran into a few hiccups with simulating the full process- individually, each operation was easy to simulate, but when I tried to run them together in series I would sometimes run into issues. For example, one common issue was the coordinate systems for my setups would sometimes become inconsistent and both setups would cut on the same side of the material. Other times, I would be able to simulate all of the operations, but my computer would hang for long periods of time and occasionally freeze, particularly during the adaptive clearing operations. In a few cases, even when I was able to get through almost the entire simulation, the last two operations that removed the excess material would appear to not complete, leaving some parts of the model with filled-in spaces between the other “arms” of the grid.

To simulate the entire process, I simulated all of the operations in Setup 1, saved the stock, then reopened the partially-milled stock in Setup 2 and simulated all of its operations to get the final result. This video shows the milling process (I'm not sure why it screen-recorded so weirdly): https://drive.google.com/file/d/17ETpTbmbmB_Xa7qA...

The final result is shown in the screenshot above!