Introduction: DIY Glowing Phone Case From Laundry Detergent + Aluminum Mold / Fantastic!

Hello, friends! Today, let’s start with something curious — this phone case.

During the day, it charges from regular light, and at night it glows like real phosphor. And yes, I made it myself — from whitening laundry powder and a couple of other ingredients I’ll share with you in a moment.

We’ll also make an aluminum CNC mold for injection molding. This mold can produce phone cases or any other parts from our silicone glowing mix in just a few seconds. But let’s go step by step.

Supplies

- Laundry detergent (which contains the components listed below)

- Baking soda

- Starch

- Silicone sanitary sealant — I’ll tell you more about it a bit later

- CNC aluminum mold

- Respirator

- Gloves

- And a few other accessories.

Step 1: Making the Glowing Mix

I start with whitening laundry powder — it contains anionic and nonionic surfactants, zeolites, phosphonates, polycarboxylates, enzymes, and optical brightener.

Inside, along with the white powder, there are blue granules.

I measure out 10 g of powder.

Add a bit of starch (for viscosity).

About 5 g of baking soda — to alkalize and stabilize the optical brightener.

The optical brightener absorbs ultraviolet light and re-emits it as a soft blue glow — like a white T-shirt under UV light in a club. Baking soda helps release these molecules, while zeolites and polycarboxylates prevent them from clumping.

As a binder, I use oxime-based silicone sealant — in an alkaline environment, it disperses the particles better and protects them.

Step 2: First Purpose of the Mold

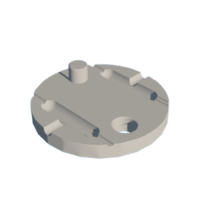

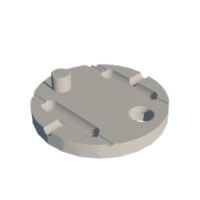

This mold was originally made for wire insulation and preliminary testing. I sent the two-part model for manufacturing to JLCCNC. JLCCNC is your trusted CNC machining partner — fast, affordable, and high-precision. Whether you’re making a prototype or starting mass production, they bring your ideas to life exactly as designed.

Why choose them:

💰 Great pricing — from one part to thousands, no hidden fees.

⚡ Speed — parts manufactured and shipped in just 3 business days.

🎯 Reliable quality — 3-, 4-, and 5-axis machines with dimension and surface checks at every stage.

🛠️ Material choice — aluminum, brass, stainless steel, and more.

Ordering was super easy: I uploaded the ready file (you can upload several), selected the material (aluminum), the finish (anodized or sandblasted), paid — and that’s it.

A week later, the mold was in my hands. Perfectly smooth, no burrs, and the parts come out easily without any release agent.

📌 Special Offer:

Starting at just $1, click here to get the $70 coupon at JLCCNC: https://jlccnc.com/?from=cncruh

#JLCCNC #romanursuhack #INSTRUCTABLES

Inside the mold, there are two configurations: for connecting two wires and for three — useful for testing different setups.

Step 3: Hot Glue Test

First, I poured in transparent glue — it set perfectly, no bubbles. Then I tried red glue — it’s denser, cools slower, but holds the shape even better.

Next, I want to design an injection mold for full-size silicone phone cases, figurines, and other parts. But before that, it’s important to see how the mix and mold construction behave in practice.

Step 4: Silicone Case Experiment

I rolled silicone into a 3–4 mm sheet, placed the phone, and fixed it with paper. I checked where the material pressed tighter and where it was softer — this will help perfect the future mold.

Step 5: Glow Test

I charged the piece under the sun, then went into the dark — it glowed with a soft greenish-blue light. With yellow dye, it turned into a beautiful bright green shade.

Conclusion

The wire mold handled the task perfectly and proved that the technology works. Now it’s time to move on to molds for full-scale case production and other elements. In the meantime, we already have a working prototype that can be charged with light and admired in the dark.