Introduction: DIY RGB LED 120mm Fan (Completely 3D Printed!)

Hi everyone! This is my entry for the New Year, New Skill Fusion 360 contest. I am a Construction Management student at Western Carolina University, but in my free time I love to design and 3D print functional and aesthetic things. I recently built a PC for 3D design work and wanted to personalize it a little bit. One of these upgrades I wanted to have on my build were some glowing ring lights around the 120mm fans located at the front of my case.

The lights I chose are some high-ish quality SUPER bright aRGB lights that generate a decent bit of heat, so I came up with a way to cool the LEDs behind the 3D printed diffuser without leaking too much light out the sides of the case. There are some weird airflow shenanigans that happen between the blade tip and the inside edge of the case in a 120mm fan case. From what I understand, if the case has a positive pressure inside, air will escape through the gap between the blades and the fans case creating a turbulent ring of air around the edge of the fan blades. In theory, the plan is for that escaping/entering/turbulent air to work its way behind the diffuser and cool the LEDs to prevent them from getting too hot. It doesn't need to be too much, just enough to disturb the airflow. I am not an aerodynamic professional, all I know is that this setup prevents the LEDs from overheating, which is a win in my book.

A new skill I used during this project was using section analysis to optimize the gap between the diffuser and LED strip.

Supplies

- Black PLA

- White PLA

- RGB strip

- 4 M4x50 bolts

- 4 M4 nuts (regular or locknuts, the former is recommended)

- RGB strip solderless connector

- 120mm fan

- method of controlling the LEDs

- extension cable for LEDs

Black PLA: realistically, this can be any color you want for your theme. This filament will make up the main body and aesthetic cover of the LED fan mod so when the LEDs are not on, this color will be more visible. I picked black because my PC case is black and that is where this LED mod is getting installed. I used snapmaker PLA, but PLA is PLA and whatever brand you like will work.

White PLA: the second color you choose needs to be white or clear. I have been experimenting with using white PLA printed very thin to act as a light diffusion material, I am talking about 1-3 layers thick at max. For my light diffusion component, I used cool white ESUN PLA. White GST3D PLA could be used here, but in my opinion it is too transparent, I wanted a more opaque filament to diffuse the LED light with. White ESUN PLA + https://www.amazon.com/dp/B01EKEMFQS?ref=nb_sb_ss_w_as-ypp-ro-model_ypp_ro_model_k0_1_9&&crid=M2I0FKRBKTVH&&sprefix=esun+pla+

RGB strip: you can use either 3 pin addressable RGB (aRGB) or regular 'ol 4 pin RGB strip lights. For this project I will be using the 3pin aRGB lights. "Addressable" means that every LED can be controlled individually by the controller, which means that an aRGB strip can do cool stuff like rainbows. The process will be roughly the same with both except for the fact that one is 3 pin and the other is 4 pin. I will touch more on this a bit later. I also recommend getting an LED strip where the LEDs are very close together on the strip, like the ones I have. Link to the strips I bought: https://www.amazon.com/gp/product/B09BDX42HL/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1)

RGB strip solderless connector: with these, it's just important to make sure you are getting 3 pin or 4 pin based on which type of LEDs you end up going with. I will eventually solder mine, as its better for longevity, but I will leave it up to you on what you end up going with. These things are ridiculously easy to work with and you can fix your mistakes relatively easily.

aRGB controller: inside a PC, many modern day components have RGB and aRGB headers on them that you can control through a software. since I am connecting a lot of LEDs to my GPU aRGB header, I am using an aRGB repeater which draws power from the power supply via a SATA connection.

Extension cable for LEDs: I scoured amazon for a long time trying to find 3 pin aRGB extension cables to use in my PC but to no avail, so in their absence I will be using 4 pin extension cables and just not using one of the wires. may cause some confusion later on (yours and mine) but we will get through it together and I won't detonate any LEDs.... maybe. Link is here:

https://www.amazon.com/gp/product/B072MLLF3P/ref=ppx_yo_dt_b_asin_title_o04_s01?ie=UTF8&psc=1

TOOLS:

- 3D printer

- scissors or flush cutters

- box cutter or razor blade

- M4 key

- wrench for M4 nut

- soldering iron (optional)

- wire stripper (optional)

Step 1: Printing the Files

Print instructions:

Infill: 10-15%

Walls: 2

Bed adhesion: optional, but brim if you generally have issues with getting parts to stick, I will never recommend using glue stick, give the bed a wash with some soap and water if recommend by the manufacturer and dry with a paper towel if the parts start to warp.

No Supports (unless the diffuser starts to warp... then you might need them)

All files have been optimized to work with the shrinkage of printing in PLA

Step 2: Measuring and Cutting LED Strips

Next we do a dry fit of the LEDs before we cut them. If you are using the same LED strips as me, there are 51-53 LEDs per fan ring. Different LED strips will have different spacing between the LED chips themselves so if you aren't using these exact LED strips, you will have to measure yourself.

Fold one LED over like the picture above and and hook that LED through one of the slots on the inside ring of the LED ring body and coil the LED strip along the inside lip. Pay attention to the direction of the arrows. Cut it once it loops back around.

Step 3: Wiring LEDs

In this step, soldering is optional. Personally I tested with the clip on connectors first and then soldered once I got it correct. The connection will be better if you solder, but the clip on connectors should work just fine. I'm not going to explain how to solder because It works basically the same way.

Ok, now it is time to wire up your LEDs by using a 4 pin extension cable as a 3 pin extension cable.

Cut a header off of the cable and strip about an inch of the thick black insulation off. You will see 4 wires.

3 pin aRGB:

Skip straight to the next blurb if you get confused easily (Don't worry I also get confused easily). Forget everything you know about wire colors for a sec. those 4 wires are Ground, Red, Green, and Blue. aRGB LEDs work on a completely different principal that I will not explain because I have exams this week and there are people on youtube that can do a better job than me. ALL YOU NEED TO KNOW is that the black wire is +5v and it is the one the arrow is pointing to. By looking at the picture above comparing a 3pin and a 4pin, you can see that the 4pin does not have a labeled ground, but the Blue pin is in the same location as the 3pins ground, this means that the blue wire is now ground. Same goes for green, its the signal wire. just cut off the red wire because you don't need it anymore.

If that made no sense to you, do not worry about it, just look here:

Black: +5v

Green: Signal

Red: cut it

Blue: Ground

If you are holding the LED strip like I am with the arrows facing the right (which is important, they will only work if the arrows are pointing away from your solder connection) the top down ordering of wires are:

Top: Blue

Middle: Green

Bottom: Black

4pin RGB:

Just line the wire colors up with what they are on the LED strip, Red to Red, Green to Green, Blue to Blue, and Black to 12v

Next step is to test it to see if your wire colors came out correctly. I recommend cutting off one pixel from the strip and testing your wire setup on just one so you don't kill the whole strip if you wire it incorrectly. If using the solderless connectors, you may need to trim down the sides of the strip on the LEDto get it to fit in the connector, just make sure you don't damage the resistor This is basically just practice for the real thing. Once you are ready to solder or clamp on a connector, attach it to the folded over LED on the strip.

IMPORTANT: You need to make sure that the arrows are pointing away from your solder connection, if you do this backwards, you could fry the aRGB 3 pin LEDs

ALSO IMPORTANT: If using 3 pin aRGB LED strips with the extension cable just as I have shown, the arrow on the extension cable need to line up with the header pin marked "5v" on the board which is driving your LEDs. Make sure you do not flip this around. If your LEDs are not working or only green, you messed up and you need to double check your wiring.

I like to use heat shrink on solder connections, it is recommended. I suck at soldering sorry.

Step 4: Peeling Off the Sticker and Attaching LEDs

Arguably one of the more "non-reversable" steps of this process.

My recommendation for peeling off the LED sticker is to take you razor blade and carefully put it between the strip and the sticker backing, then twist the blade to tear the sticker right after your solder connection to start where you you will peel off the sticker.

I recommend peeling off an inch or so of the sticker back at a time.

Getting the LEDs in the correct place can be a little complicated. The bottom edge of the LED strip needs to be pressed flush with the bottom lip of the body in order to have the diffuser clear the LEDs to provide the space to cool them. I recommend pushing down with your index finger on the edge of the strip as you stick it to the wall with your thumb. Check the images above to see an example of me applying pressure with my index finger. Just walk your way around the entire strip to get good fitment.

IF LEDs STRIP IS NOT STICKY AFTER PEELING OFF STICKER BACK:

If you peel the sticker back off of the LEDs and find that the strip is not sticky, do not panic. The adhesive likely got stuck to the paper backing during soldering. all you need to do is the razor blade trick but farther down the strip. When you cut it, peel it back towards the solder connection and the adhesive should "unstick" from the paper and you can just push it back on the LED strip and be good to go.

Step 5: Assembly and Installation

All that's left now is the final assembly and install.

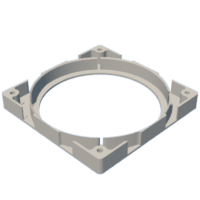

How you install it and where you put it is ultimately up to you, but I opted to put the RGB ring fans at the front of my PC case. For each light ring you will need 4 M4x50 screws and their accompanying bolts. All 3 printed parts will sandwich together with the top plate on top, diffuser in the middle, and the body on the bottom. If this is confusing, just look at the pictures, I took a lot of them. I recommend putting the fan on the back of the stack, as this is the aesthetic I was originally going for, but it could easily go either way. This fan was just a fan I had laying around that I used for measuring purposes... your fan should have blades on it.

I recommend hand tightening the screws. If you are using lock nuts (which I recommend over "regular" nuts) you will need a wrench and key to get them on, just don't crank them as tight as you can force it, just get it to a tightness which wont be able to easily vibrate loose.

Step 6: FAQ

Q: Why didn't I just buy RGB fans?

A: I really didn't like any of the looks of ones currently on the market. I have had a certain aesthetic in mind for this project, I wanted my RGB fans to look a certain way and nothing on the market currently satisfied what I wanted. So I made my own

Q: What makes these different from other RGB fans?

A: for one, the LEDs contained in these rings are much denser. there are 52-54 individual lights contained in one ring, this makes for some smooth LED "animations" or effects as the lights are so close they seem to pass the light from one to the other without any significant dark spots between the LED pixels. These LEDs are also massively brighter than premanufactured LED fan rings, bright enough to leave spots in your vision if you look at them without the diffuser. Bright also translates to the amount of heat produced, so these ring lights have a feature of being actively cooled by the fan itself. You'll notice that the diffuser has all sorts of cutouts in it, these are holes designed to increase the airflow over the LEDs to keep them cool.

Q: Why not use a commercially available light diffusing material instead of a 3D printed part?

A: The goal of this project was to make something that anybody with access to a 3D printer could make for themselves. I try to stay away from "niche" materials such as light diffusers because of how uncommon or expensive they can be online, not to mention finding a reputable and reliable seller to post the link for. This is why the light diffuser is 3D printed. Printing the light diffuser yourself out of white PLA also has the added benefit of being cheaper than anything commercially available and you don't need to do a ton of "cone math" to figure out how large and what strange shape of diffusion material you would need to create the sloped surface. I will play more with 3D printed diffusion components soon.

Q: What kind of LED driver are you using?

A: I am running my LEDs off of a 3-pin aRGB connector on my EVGA graphics card. If you are installing these in a PC, you could use your motherboard, I just chose my GPU because I liked the aRGB options better. I also recommend an RGB repeater if you plan on using multiple of these. These use a SATA power connector to supply the LEDs with power straight from the power supply. Something like the Corsair Commander or a cheap $15 one from amazon.

Please ask any and all questions you may have.

Thank you for reading this far.

Second Prize in the

New Year, New Skill Student Design Challenge