Introduction: Dead Drop Spike V.1

This is a project I made a little while ago as a birthday present for my friend Daniela who introduced me to geocaching. It is based on several designs I saw in a book on spy gadgets. They would have been used for passing stolen documents and film between an agent and their handler, storing money and documents as well as other tasks.

I've just completed an Instructable for version 2. It adds a locking lid and a D-ring to seal it.

Here's what you need to make your own:

Tools:

• Pipe cutter (optional)

• Hacksaw

• Metal working lathe with cross slide

• Drill or drill press (optional)

• 1/4 inch drill bit

• Mill and 1/4 inch milling bit (optional)

• Countersink (optional)

• Needle nosed pliers

• 1/8 inch diameter nail

• Applicator (and mixing dish if using 2 part epoxy)

Materials:

• 3/4 inch external diameter, 5/8 internal diameter, aluminum pipe, 3 1/2 inches long

• 3/4 inch internal diameter aluminum pipe, 1 1/8 inches long (The external diameter does not really matter. The piece I used was about 7/8.)

• Two sections of 3/4 inch diameter aluminum rod. One section 1 5/8 inches long, the other 1 1/8 inches long

• 8 inches of 1/16 of an inch diameter SS wire

• Epoxy intended for use with metal

• Strong string

Step 1: The Sidewall and Point (the Body)

Cut the 3/4 inch external diameter pipe to length (3 1/2 inches). If you are using a pipe cutter be sure to round off the burr that is formed. This will make up the side wall of the spike.

On the lathe turn a 1/2 inch long section from the end of the 1 5/8 inches long section of 3/4 inch aluminum rod down to a 5/8 diameter.

On the lathe turn a point on the opposite end from the one you just turned down.

This piece will be the point.

These two parts make up the body.

Step 2: The Collar and Top (the Lid)

Cut a 1 1/8 inch long section of 3/4 inch internal diameter pipe. This piece will be the collar.

A. Take the 1 1/8 inches section of 3/4 inch rod and drill a 5/8 inch deep hole in one end.

B. (optional) Mill two 3/8 of an inch long, 1/4 inch wide, grooves on opposite sides of the undrilled end.

C. If you have milled the grooves, then drill a hole 1/4 of an inch from the end from one groove to the other. If you have not, then drill a 1/4 inch hole through the rod 1/4 of an inch from the undrilled end and countersink the holes. This piece will be the top.

These are two of the three parts that make up the lid.

Step 3: The Spindle

Bend the wire over the nail at a point as close to the center of the wire as possible. Trim the ends of the wire so that it is 3 1/2 inches long. This piece will be the spindle.

This is the third part of the lid.

Step 4: Gluing

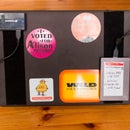

Test fit all parts together as shown in the above image. Glue all parts together following the instructions for your epoxy.

It is easier to glue the spindle into the top before gluing the collar on.

At this point, you can put the lid in the lathe to round off the upper edge of the collar, however it is not necessary.

After the glue has dried, tie the string through the hole in the lid.

Step 5: You're Done

There are a few ways that you can wind paper onto the spindle. The spindle has space for a strip of paper up to 2 3/4 inches long. The way I have set it up is to make a small notebook out of waterproof paper. I think it would be slightly easier on the notebook if you thread it onto the spindle just past the staple, however, if you are using it for geocaching and it will be handled by people who are unfamiliar with the spike, I would suggest threading the notebook around its middle as it is less likely for it to slip off when you are opening and closing the spike.

Participated in the

Spy Challenge

Participated in the

Make It Real Challenge