Introduction: Diy 3d Printed Axial Flux Generator&motor2

Hello, I am currently an electrical engineering student at Ulsan University in Ulsan, Korea. This is the first time I am posting my product on an Autodesk instructable.

Currently, as eco-friendly businesses are emerging due to global warming, electric vehicles are being mentioned a lot in the media. I was also interested in electric vehicles. I was particularly interested in the mechanism of the driving motor of this electric vehicle. So, for educational purposes and as a hobby, I made an Axial flux motor, a power motor used in Mercedes-Benz electric vehicles, with a 3D printer.

1. Motor operation video:

https://youtube.com/shorts/nZOSKriP3TE?si=MhP31xbssDl5GuQa

2.Motor circuit diagram:

https://youtube.com/v/SEvCtlEv9mc?si=8ERCLMvLMzko2yFj

3. Video of a motor operating as a generator:

https://youtube.com/v/142aNaD5coE?si=v7tgKgihxhPWrd2E

4. Modeling assembly video:

https://youtu.be/9-d7VQjLpJ8?si=UWPsTBcdFQSvqRir

5.STL_file:

https://grabcad.com/library/diy-3d-printed-axial-flux-generator-motor2-1

https://www.thingiverse.com/thing:6634709

6.https://youtu.be/2GnJRIuoVQA?si=AM51PqO2jQUCo6DX

7.https://youtu.be/0p7ja2s9ugs?si=fhK2S3rnA28wrPPW

*Modeling was done directly using a program called Inventor.

Supplies

The materials used in this project are

1. [M5 bolt and nut]x10

2.[Bearing=806zz]

3.[Tapping screw for M5]

4.[Axis=>

Length: 100mm

Diameter:8mm

]X1

5.Coil=>

diameter 0.8mm

6.[Neodymium Magnet 5T]x12

7.[ESC 40a 4CELL]x1

8.[cable tie]

9.[paper punching machine]

10.[3d printer]

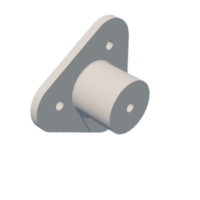

Step 1: PART PRINTING1

Print motor rotation parts.

Step 2: PART PRINTING2

Print motor case parts.

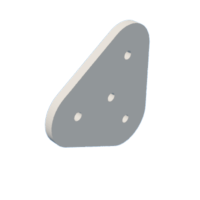

Step 3: COIL WINDING1

This is a fixture for winding the coil. Here, the coil was used with a thickness of 1mm. The bolt used is M5 brass material.

Step 4: COIL WINDING2

Wind the coil 110 times by hand.

Step 5: COIL WINDING2

In this way, the triangle-shaped coil is completed.

Step 6: COIL WINDING3

Makes 6 of these.

*(The square metal visible in the photo is a converter.

Converts the 3-phase induced electromotive force generated when using the motor as a generator into direct current power. )

Step 7: Attaching Bearings and Axles to Case Parts

Install the shaft and bearings on the printed case part. Here, the shaft is 100mm long and 8mm in diameter, and the bearing is 806zz

Step 8: Mounting the Coil to the Case Part1

Attach the 6 triangle coils you made to the case parts. Secure with cable ties.

Step 9: Mounting the Coil to the Case Part2

Secure the remaining coils with cable ties.

Step 10: Wiring the Motor Coil 1

This is the motor coil wiring diagram.

There are three phases in total: Phase A, Phase B, and Phase C.

The coil wiring is Y-connected.

This final line is also like this

Connect the coil.

******

ESC=>Speed controller is 40A 4cell (rated voltage: 14.8v, 3.7v per cell)

Here, ESC converts direct current power into 3-phase power and excites each phase A, B, and C per hour.

It plays a role.

Step 11: Wiring the Motor Coil 2

Connect each coil Y according to the wiring diagram.

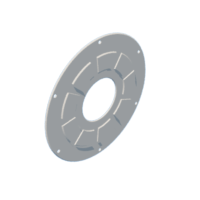

Step 12: Cutting Sheet Metal1

Cut the steel sheet into a circle to fix the magnet to the rotating part of the motor.

Step 13: Cutting Sheet Metal2

Bolt to a rotating part printed on a circular steel plate.

We conclude. Here, a punching machine is used on a circular steel plate.

Used to create bolt insertion holes.

Step 14: Cutting Sheet Metal3

Attach the prepared magnet to the circular iron plate.

Additionally, strong adhesive is applied.

Step 15: Check Coil Wiring Operation

Perform a continuity test with a hook-on meter or multimeter to check whether the coils are wired correctly and check the resistance value of each coil.

Step 16: Combine Each Printed Part.

Combine each printed part.

[Assembly]:

https://youtu.be/9-d7VQjLpJ8?si=UdKYsCsSL2245KDS

Attachments

Step 17: Completion

completion ^^

Attachments

Step 18: Check Motor Waveform

To verify that the motor is operating correctly, use an oscilloscope to check whether a sine wave appears in each phase. If not, please check the coil wiring again!

[test]:

https://youtu.be/eq9CBu-UdhU?si=4L1-OF7XKnlePEE-

Step 19: Analyzing Electric Motor Electromagnetism

You can just skip this process.

If you have a program called ansys maxwell,

Try it as an experiment