Introduction: Freefall Pendulum Clock

This project is an electro mechanical pendulum clock with a difference.

The main difference being in how the pendulum operates, rather than using the period between successive swings as in a conventional clock this clock uses the total time from when the pendulum starts to when it stops swinging. How this is accomplished is explained in the text.

The vast majority of the clock is 3D printed with the exception of the control which is electronic.

Used the prefix Freefall as its function may be clearer in recognition rather than from a scientific perspective as an Underdamped Pendulum Clock.

Size: 50(H) x 179(W) x 13(D)

Supply: 5V / 90mA

Updates:

1: The GIF is the full swing sequence compress into ~8 seconds. However, it may give the impression that the bob on the end of the pendulum is bouncing which is not the case. To more clearly illustrate the process I have added a longer video sequence taking ~38 seconds. 15 Dec 2025

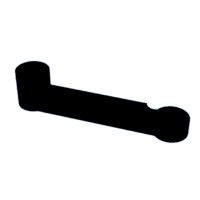

2: Updated the hanger to increase the thickness by 3mm to improve vertical alignment. 20 Dec 2025

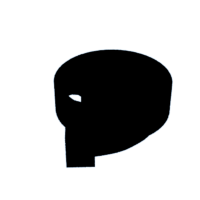

3: Modified the design of the semicog to add a flange coupling connector as the stresses at the fixing centre proved too great resulting in slippage. 20 Dec 2025

4: Changed the location of the motor sensor from the right to the left to allow the semigear to fully clear the pendulum gear rather than stopping just after releasing the gear to prevent gear lock. 21 Dec 2025

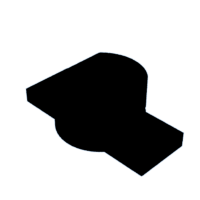

5: Modified the design of the catcher from two pieces to one piece, removes the requirement for one screw simplifying printing and installation. 24 Dec 2025

6: Updated the circuit to include current source charging for the timing capacitor and using the control pin to vary the time period. This is to allow variation of the dead time delay when the pendulum stops to adjust the time faster or slower inconjunction with an optimised pendulum. 2 Jan 2026

Attachments

Supplies

Pin headers - Straight through hole single row

In line sockets 2.54mm pitch 3 pin - Qty 4

1kR SMD 1206 - Qty 4

1k2R SMD 1206 - Qty 1

10kR SMD 1206 - Qty 10

12kR SMD 1206 - Qty 1

2k2R SMD 1206 - Qty 1

47kR SMD 1206 - Qty 2

100kR SMD 1206 - Qty 1

100nF SMD 1206 - Qty 9

10nF SMD 1206 - Qty 1

20uF/10V Electrolytic Thru hole - Qty 1

100uF/10V Electrolytic Thru hole - Qty 1

FMMT624 NPN SOT23-3 - Qty 5

TL551 SOIC-8 - Qty 2

ZXMS6006 INTELLIIFET SOT223-3

DRV5032 TO92-3 - Qty 2

Springs 0.3(wire) x 3(dia) x 10(L) mm

Bearing 15(OD) x 13(ID) x 4(H) x 5(Bore) mm - Qty 2

Bearing [MF63ZZ] 7.2(OD) x 6(ID) x 2.5(H) x 3(Bore) mm

Brass rod 2(dia) x 20(L)min mm - Qty 2

Brass rod 3(dia) x 50(L)min mm - Qty 3

Brass rod 5(dia) x 110(L)min mm

Stainless Steel Rods 6(dia) x 215(L) mm - Qty 4

M2.5 X 10mm machine screws - Qty 4

M2.5 X 10mm machine screws

M2.5 X 12mm machine screws

M2.5 x 15mm machine screws

M2.5 X 25mm machine screws

M2 x 8mm self tapping screws - Qty 2

M3 x 10mm machine screws - Qty 5

M3 x 8mm machine screws - Qty 13

M3 x 12mm machine screws

M3 x 15mm machine screws

M3 x 25mm machine screws

M3 threaded standoff 15mm - Qty 4

Micro metal gear motor (1006:1 , 14RPM)

Flange Coupling Connector 3mm centre

May prove more cost effective to buy a range of values rather than individual values unless you already have them available. Some components may also have a MOL greater than the quantity specified in the component list.

No affiliation to any of the suppliers, feel free to obtain the supplies from your preferred supplier if applicatble.

Links valid at the time of publication.

Tools

3D Printer

Needle files

Sanding paper

Craft knife

Soldering Iron

Solder

Adhesive tape

Wire cutters

Screwdriver (tip profile subject to screw head)

Pencil

Drill

Drill bit 1.5mm

Drill bit 2mm

Drill bit 3mm

Drill bit 6mm

Wire Wrapping Tool

Step 1: Background

Thinking about a number of clock projects I had in mind a more mechanically operated clock more closely resembling a traditional clock. But at the same time I envisioned something a little different.

A pendulum clock but one with a difference sprung to mind.

I decided that there would no microcontroller or RTC but there would be some sort of electronic control.

The electronics would control the pendulum and the pendulum would control the clock.

The result was an undamped (freefall), pendulum clock.

This is a first version as a result of this process identifying a number of areas to be revisited which I have identified in the text.

The result is a functioning clock if not the most accurate but part of the challenge was turning an idea into reaity.

Step 2: CAD Design

The 3D printed elements were designed using BlocksCAD, with all sliced using Cura 5.8.1 and printed on a Elegoo Neptune 4 Pro.

Attachments

tipper_armescp2.stl

tipper_armescp2.stl tipper_armspacer.stl

tipper_armspacer.stl tipper_cup.stl

tipper_cup.stl tipper_dials.stl

tipper_dials.stl tipper_drivepawl.stl

tipper_drivepawl.stl tipper_escape30.stl

tipper_escape30.stl tipper_escpt1.stl

tipper_escpt1.stl tipper_frame1.stl

tipper_frame1.stl tipper_frame2.stl

tipper_frame2.stl tipper_frame3.stl

tipper_frame3.stl tipper_hourhand.stl

tipper_hourhand.stl tipper_lever.stl

tipper_lever.stl tipper_lockpawl.stl

tipper_lockpawl.stl tipper_minutehand.stl

tipper_minutehand.stl tipper_mtr_support.stl

tipper_mtr_support.stl tipper4_2ndsupport.stl

tipper4_2ndsupport.stl tipper4_armsupport.stl

tipper4_armsupport.stl tipper4_cogs_sensor4.stl

tipper4_cogs_sensor4.stl tipper4_corner2.stl

tipper4_corner2.stl tipper4_pendbase.stl

tipper4_pendbase.stl tipper4_pendhanger.stl

tipper4_pendhanger.stl tipper4_pivot2.stl

tipper4_pivot2.stl tipper4_uprights3.stl

tipper4_uprights3.stl tippercogs3_bev20t.stl

tippercogs3_bev20t.stl tippercogs4_sensorcov.stl

tippercogs4_sensorcov.stl pcbholder.stl

pcbholder.stl magdrive3_cog60ep_p75.stl

magdrive3_cog60ep_p75.stl magdrive3_cogs60_p75.stl

magdrive3_cogs60_p75.stl magdrive3_dualcogs1560_p75.stl

magdrive3_dualcogs1560_p75.stl magdrive3_dualcogs2060.stl

magdrive3_dualcogs2060.stl magdrive3_escape_spacer.stl

magdrive3_escape_spacer.stl magdrive3_spacer.stl

magdrive3_spacer.stl tipper4_hanger2.stl

tipper4_hanger2.stl tippercogs3_bevsemicog7t3rev.stl

tippercogs3_bevsemicog7t3rev.stl tipper_catcher.stl

tipper_catcher.stl

Step 3: 3D Printing

Filament: PLA in any colour as suits personal choice.

Layer Height: 0.15mm

Infill: 100%

Bed Adhesion: Skirt

No supports

All parts are correctly orientated within the files for printing directly.

Its recommended to print the gears individually to minimise possible displacement errors.

Although, PLA has been used other materials with superior wear properties could be used to minimise wear. Such as Nylon or ABS (Not exhaustive as other materials will likely exist that may be equally or more superior for the task.)

Step 4: Circuit

The pendulum is operated by the electic motor attached to a semi gear wheel which rotates against a a full gear wheel that raises it from its stationary vertical position to a position above the horizontal.

Once the semi gear has rotated past its last tooth the motor stops and the pendulum falls and will continue to swing until it eventually stops.

The pendulum having stopped the motor will restart to repeat the swing.

At the top of its pre start condition it will advance the clock 1 minute.

This activity is controlled by the electronic circuit in conjunction with two sensors.

The sensors are Hall effect types which in conjunction with magnets monitor the motor and the pendulum.

The magnet associated with the motor is fitted to the semi gear towards the end of the the toothed section.

When the magnet is in close proximity to the sensor the motor will stop or restart if it has previously stopped and the conditions that initiate the motor are met.

In line with the bottom of the vertical position of the pendulum at rest is fitted a Hall sensor and at the end of the pendulum is fitted a magnet.

The proximity of the magnet to the sensor and the delay between successive swings determines whether the pendulum is in motion or has stopped.

Whilst the pendulum continues to swing the MMV (monostable multivibrator), is retriggered preventing it timing out.

When it stops the MMV will timeout.

The MMV is created using a 555 timer or equivalent.

The timeout for the MMV ends when the voltage across the timing capacitor (Ct), reaches 75% of Vcc but if it discharges before this level the timeout period can be extended.

This is accomplished by connecting a transistor pair cross the capacitor (Ct), which when switched on presents a low resistance path across the capacitor, discharging the capacitor

With the transistor pair off Ct charges via Rt.

The MMV timeout = 1.1*Ct*Rt = 1.1 * 22uF * 220K = 5.324 seconds

At switch on the MMV output is low due to the POR (power on reset), RC network connected to the Reset pin.

A similar POR is applied to the D type FF's

The MMV is triggered when the output of the Hall sensor goes high in the absence of a magnetic field each time the pendulum swings passed the sensor.

Clock pulses from another 555 timer trigger the MMV during the time the pendulum swings past the sensor preventing it timing out as long as the pendulum is swinging..

This clock pulse also gates the D type FF

The output of the MMV is simultaneously fed to the D input of the D type flip flop (FF), via an RC delay (~5mS min), and a network of NAND gates. The output of the D type is also fed to this NAND network.

Additionally, the motor Hall sensor also connects to this NAND network.

At switch on with the pendulum at rest and the motor stationary both sensor outputs are low.

The output of the Nand network clocks a D type FF configured as a Divide by 2 counter, its output is low but is inverted and drives a *SMART FET that switches the motor on.

The motor begins to turn raising the pendulum and both their sensor outputs are high.

The MMV is triggered and the clock of the counter goes low.

When the motor has competed its cycle the Motor sensor transitions from a high to a low output amd the MMV and its companion D type FF both have high outputs. The output of the NAND network goes high and the motor switches off.

The pendulum swings and the output of its sensor pulses with each transition retriggering the MMV.

Once the pendulum stops the output of the sensor goes low which disables the clock pulses sent to the MMV.

The MMV will timeout and both its output and that of the D type will go low.

However, the MMV will cause the output of the NAND network to go high to low, the delayed pulse from the D type will cause the output of the NAND network to go low to high. Clocking the counter and changing its output state.

This will restart the motor for the next cycle.

There are three LED indicators, Mstat (motor enable), when on motor enabled, SSI (swing sensor), on when the pendulum is at or passes the vertical position, MSI(motor sensor), on when the motor is at the home position.

*I opted to use a IntelliFET as this has the advantage of being self protecting (over voltage, over current & over temperature), particularly if the motor stalls.

Step 5: PCB

The PCB is double sided and was designed using EagleCAD and manufactured at OSHpark.

Its always worth visually examining the board and checking vias with a DMM to ensure connectivity, particularly if they will be hidden by a component as its much easier to remedy prior to assembly.

Board Size: 79.79(W) x 59.7(D)mm with 3mm mounting holes in each of the 4 corners.

The majority of the components are SMD with a few thru hole capacitors, LED's and the pin headers.

Optionally the LED's can be mounted in a prominent location (at the front of the clock), remote from the PCB.

There are a small number of manual changes required which due to time constraints it was not possible to redesign the PCB in time. These changes do not require any modifications to the PCB itself just component changes.

1: C4/C15 connect a wire link at C4 or C15

2: D1 omit the component

3: C3/C14 populate one only.

Reflow soldering could be employed but hand soldering is also possible which is how I assembled it.

If hand soldering be extra vigilent for open and short circuits.

Use a magnifier to visually inspect between IC pads and component orientation, if in doubt check with a DMM prior to applying power.

Provision is made for connections to the PCB by pin headers or directly to the pads, if soldering direct to pads be sure to minimise resoldering and excessive heat to prevent pad lift.

Orientate, the PCB support such that the section with full holes are at the bottom and align the PCB with connects towards the same end.

Screw the PCB to the PCB support bracket with 4 x 2.5 x 10mm machine screws put plastic spacer washers between the PCB and support and fit nuts on the back.

Step 6: PCB Functional Check

Before fully fitting the PCB in place and wiring up all the sensors and the motor.

Its worthwhile checking that everything works as expected.

Having extra Hall sensors I soldered each of the sensors to 3 pin headers.

Verify the pendulum sensor.

Connect one Hall sensor to the pins referenced by SSI.

Apply power to the pins 0V and 5V.

Put a magnet against the front face of the Hall sensor and the LED should illuminate.

Remove the magnet and its associated LED should extinguish.

If the LED does not behave as described power off and recheck the circuit.

Remove power.

Verify the motor sensor.

Connect one Hall sensor to the pins referenced by MSI.

Apply power to the pins 0V and 5V.

Put a magnet against the front face of the Hall sensor and the LED should illuminate.

Remove the magnet and its associated LED should extinguish.

If the LED does not behave as described power off and recheck the circuit.

Remove power.

Verify the motor.

Once the individual sensors checks have been run the combined effects need to be verified.

Connect both Hall sensors to SSI and MSI.

Connect the motor to the pins Mtr (Red wire), and 5V (Black wire).

The motor will rotate clockwise or anti clockwise subject to the polarity or the supplies.

Apply two single magnets against each sensor. (MSI = L, SSI = L)

The motor LED should illuminate and the motor shaft (a slip of coloured tape will serve as a visual indication of operation and direction of rotation), should rotate.

Apply the following sequence to the sensors.

Where: H = No magnet, L = Magnet applied

SSI MSI ME

L L On following delay

H L ON

H H ON

L H OFF

L L On following delay

Step 7: The Main Support

One main support is used to connect all the various elements of the clock.

A bearing with a 5 mm bore is inserted in the top of the support.

This is a press fit and can be secure in place by pressing between the jaws of a vice.

Be sure to separate the support from the jaws of the vice with cardboard or something similar to protect the surfaces of the support.

Screw 4 x M3 x 15mm threaded standoffs at the the end of the horizontal arms (2 each side), facing in the opposite direction to the base direction, using 4 x M3 x 8mm machine screws.

Step 8: Motor Enclosure

A bearing with a 5 mm bore is inserted in the top of the motor enclosure.

This is a press fit and can be secure in place by pressing between the jaws of a vice.

Be sure to separate the support from the jaws of the vice with cardboard or something similar to protect the surfaces of the support.

Solder two wires (red & black), to the motor of 20cm each.

Feed these through the holes at the back of motor enclosure.

Press the front and rear halves of the enclosure together and secure with 2 x M3 x 15mm machine screws.

Feed the motor spindle through the back of the main support and orientate the arms horizontally

Attache the motor enclosure to the main support with 4 x M3 x 10mm machine screws.

Step 9: Pendulum Drive

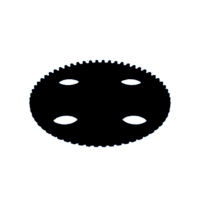

A micro metal gear motor (1006:1 , 14RPM), is connected to a 7 tooth semi gear, the teeth only covering 110 degrees of the circumference.

Prior to the start and end of the teeth are semicircular cutouts.

These cutouts allow the pendulum gear (30 teeth), to disengage with the semi gear.

The pendulum gear is connected to the spindle of the pendulum.

When the motor rotates the semi gear rotates until it engages with the pendulum gear and lifts the pendulum.

The pendulum will continue to rise until the semi gear disengages at which point the pendulum will freefall.

A Hall sensor inconjunction with a magnet attached to the semi gear stops the motor once the gear disengages.

Once the pendulum stops the motor will be switched on to raise the pendulum.

Assembly

Align the holes on the flange connector with the holes on the semi gear.

Fit 4 x M2.5 x 6 mm machine screws in to the four holes.

Ensuring the collar of the flange connector is closest to the motor and tighten the collar screws to ensure a secure fit.

Step 10: Motor Sensor

The motor sensor is a Hall sensor.

In this case its in a 3 pin TO92 package.

With the front of the package facing you, bend the leads back at 90 degrees away from you.

Pass the lead through the slot such that the main body of the component sits into the cavity.

Wire wrap or solder 3 x 20cm lengths of flexible wire to the leads of the sensor.

For clarity the wires should be colour coded e.g. Red - Vcc, Black - Gnd, White - Output

Solder the wires to a 3pin inline socket, ensuring the centre pin is connected to the White wire.

Connect the Red and Black wires to each of the outer pins.

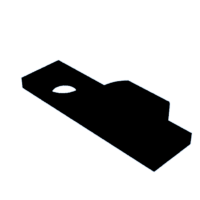

Screw the sensor plate to the sensor cover with the sensor sandwiched between the two and the sensor located to right hand side. Using 4 x M3 x 8mm screws.

Secure the motor sensor to the standoffs previously fitted to the Main support with 4 x M3 x 8mm machine screws

Step 11: The Pendulum

The pendulum consists of a steel tube the top end is attached to a T connector which enables it to be connected to the spindle.

With a 2.5mm drill bit open the 3 holes that will accept M3 x 8mm machine screws.

With a 3mm drill bit open up the vertical section of the T into which the steel tube of the pendulum wil fit.

Do not overforce the screws as they may strip the thread, split the plastic or in the case of the tube crush the body.

On the other end is a 3D printed ball consisting of 2 hollow hemispheres.

The lower hemisphere is attached to the end of the tube and the top hemishpere is a slip fit on the tube.

The duration of the swing can be manipulated by changing the weight or height of the bob.

Not applied in this version but the steel tube could be replaced with a threaded rod and plastic nuts either side of the bob to allow vertical adjustment and a steel nut on the end of the rod to which the magnet is attached.

Secure the pendulum to the 5mm brass rod with the 2 x m3 screws with the bottom centre of the bob (attached magnet), in line with the pendulum sensor.

Step 12: Pendulum Sensor

The pendulum sensor is a Hall sensor.

In this case its in a 3 pin TO92 package.

With the front of the package facing you, bend the leads back at 90 degrees away from you.

Pass the lead through the slot such that the main body of the component sits into the cavity.

Wire wrap or solder 3 x 35cm lengths of flexible wire to the leads of the sensor.

For clarity the wires should be colour coded e.g. Red - Vcc, Black - Gnd, White - Output

Solder the wires to a 3pin inline socket, ensuring the centre pin is connected to the White wire.

Connect the Red and Black wires to each of the outer pins.

Push 2 x 6(dia) mm steel straws in to the holes in the sensor plate with a visible length below the plate of 37mm.

Attach the wire to the outside of the right hand straw

Step 13: Clock Face

The clock face is printed as a separate element this allows customisation and this is held in place by a minimum of two screws although many more screw holes are positioned around both if required.

In its current form minutes are at the top (5 minute intervals), and hours (1 hour intervals), at the bottom.

The numbers are printed slightly raised which enables them to the easily hand painted as there is a well defined area which contains the paint, any overflow would fall down the side rather than bleeding sideways into a connect area on the same level which would obscure the number.

Step 14: The Clock Mechanism

The clock is in the main 3D printed with a few exceptions, these being brass rods, bearing and screws.

The time is displayed on two faces the upper one minutes and the lower one hours.

A total of four gears are required for the clock mechanism.

Two single gears (60, [60 with raised pillar; hours]), and two compound gears ([15/60 minutes], [20/60 setter])

A separate spacer is required to be placed under the 60 tooth gear with pillar.

The gears are held in place between three tiers with the associated alignment holes.

The tiers are secured with M2.5 machine screws 10mm from tier 1 to 2 and 25mm for tier 1 to 3

Time setting is easily acomplished by rotating the exposed gear [20/60], anticlockwise which will rotate both hands.

Forward rotation is not available due to the rachet mechanism.

At the bottom of the clock mechanism is a tab which is used to mount the ratchet mechanism.

The assembly sequence is shown in the supplied images.

Brass Rods

The two compound gears require a 3(dia) mm brass rod inserting in the centre hole, first open the hole with a 3mm drill bit and pressfit the rod into the centre with a pillar drill using a flat faced rod in the drill chuck.

The 15/60 gear requires a 47(L) mm rod.

The 20/60 gear requires a 37(L) mm rod.

The single gear 15/60 requires a 3(dia) x 37(L) mm brass rod.

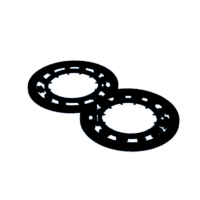

Bearings

3mm bore bearings are used to reduce friction.

Three are inserted on the first tier, one is inserted on the second tier and three inserted on the third tier.

The single 60 gear with the raised pillar for the hours requires a bearin in the top of the pillar.

These are a press fit but is difficulty is found with insertion, lightly spinning a 6mm drill bit in the hole may help.

Clock Face

Fit the clock face with 2 x M2 x 10mm self tapping screws.

Hands

Fit the hands which are a press fit.

The hands are distinctly different preventing mixing, the long hand with 3mm hole fits the upper dial and the short hand with the large opening fits the lower dial.

Step 15: Escapement Pt 1

The escapement is assembled as two main parts.

The first part consisting of a ratchet and pawl mechanism with other associated elements.

The ratchet gear has an integrated 30 tooth gear that interfaces to a single 60 tooth gear in the clock mechanism that drives the clock.

There are two pawls one locking and one driving.

The driving pawl is operated by the action of Escapement Pt 2

Some prepartion and assembly of the parts is required prior to use.

Locking Pawl

The locking pawl requires two holes to be opened out the centre hole with a 3mm drill bit and the off centre hole with a 2mm drill bit.

The hole were the other end of the spring will be attached should also be opened out with a 2mm drill bit.

Attach a 10mm extension spring with a 2.5mm machine screw to the off centre hole in the pawl.

In the location of the supporting body which aligns with the slot in the pawl open out the hole with a 1.5mm drill bit and press fit a 2mm x 10mm brass rod into the hole.

The pin can be inserted using a vice or pillar drill to press it in place.

A similar pin should also be inserted at a point at the lower right hand edge of the ratchet gear.

Place the slot in the pawl over the pin and fit the pawl in place with a M3 x 10mm machine screw and plain washer.

Do not over tighten the M3 screw as the pawl needs to move freely.

Attach the other end of the spring in place with an M2.5 x 10mm machine screw.

Driving Pawl

The driving pawl required 3 holes to be opened with a 2mm drill bit at holes 1, 4 & 6.

On to a M2.5 x 10mm machine screw slip one end of a 0.3x3x10mm spring and insert the screw in to hole 1 of the driving pawl. Repeat the same process for hole 6.

The lever requires 2 holes to be opened up with a drill bit, 3mm in hole 1 and 2.5mm in hole 5.

Fit a 2.5mm x 10mm machine screw in to hole 5 of the lever and secure this in hole 4 of the driving pawl.

Ensure the pawl and lever turn smoothly.

Place the large opening of the driving pawl over the brass pin.

Secure the lever in place with a M3 x 10mm machine screw.

Secure the free end on the tension spring with a M3 x 10mm machine screw in the hole nearest the lever fixing screw.

Secure the free end of the return spring with a M2.5 x 15mm machine screw in the last hole in the main body.

Testing the Escapement

Fit the ratchet gear between the pawls and secure in place with a M3 x 25mm machine screw.

Push the bottom of the lever forward.

This should move the gear round one position.

With tension spring keeping the driving pawl pulled towards the ratchet.

The locking pawl should be moved out of position then spring back into place preventing the gear reversing.

When released the return spring will pull the driving back to its start position.

There are addition holes on the main body to enable some adjustment, such as shorter springs.

The ratchet gear will need to be removed prior to fitting the clock mechanism.

Fit the Clock

Slide the tab on the clock into the cutout on the Escapement 1.

Refit the ratchet gear.

Check to ensure that the ratchet advances the clock 1 minute per step..

Step 16: Escapement Pt 2

The second part of the escapement is much simpler and consists of a pushing arm.

This part consists of 5 main elements

This arm is used to convert the radial motion of the pendulum into forward motion to activate the driving pawl.

The catch of the arm is positioned such that the pendulum makes contact just short of its maximum elevation.

If it is positioned much lower than this there is plenty of push but it can cause the gears to slip and affect the timing.

*The alternative is a slipping/clutch gear which protects the gears and motor making setting less critical.

I have not applied the slipping/clutch gear on this version.

Some prepartion and assembly of the parts is required prior to use.

With the longest piece orientated vertically and the side arm facing left.

Hole 1 at the bottom of the arm should be opened out with a 3mm drill bit.

Hole 8 up from the bottom should be opened out with a 2mm drill bit.

Holes 11, 13 and 23 should be opened out with a 2mm drill bit.

In to the 20mm spacer open out the hole with a 2mm drill bit.

Attach the catch to the spacer by its centre hole.

On the short left arm at the most extreme left (hole 1), open out the hole with a 2.5mm drill bit.

On the separate short piece (6 holes), with the piece orientated with the thicker sections to the right with a 2mm drill bit open out the two holes at positions 4 and 6.

Align the short piece (holes 4 & 6), to the longest piece (holes 11 & 13), and fit this to the back of the longest piece such that a ~5mm gap exists between the two parts and secure with 2 x M2.5 x 10mm machine screws.

Attach the cup to the side arm at hole 1 with a M3 x 6mm countersunk machine screw.

Attach the catcher to hole 23 of the longest piece with a M2.5 x 15mm machine screw.

Support Arm

The support for this arm has a curved slot and four horizontal hole at the front.

With the slot orientated at the top and the check the fit with a 2.5 x 15 mm screw and ensure it moves freely.

In to the third hole (hole 1 on the extreme left), open it out with a 2.5mm drill bit.

Attach hole 1 to the support arm at its 3rd hole with an M3 x 12mm machine screw and plain washer (sitting between the arm and support).

The support sits at the right hand side of the platform.

Step 17: Assembly

To the ledge bracket insert the two pendulum support tubes.

Screw the main support with attached motor support and motor sensor to the ledge bracket.

Attach the clock support and Escapement Pt 2 to the ledge support.

At this point securely attach the ledge support to a table or bench with gclamps or ratchet clamps, ensure they will not catch on the pendulum.

Attach the 20 tooth gear to the 5(dia) mm brass rod.

Feed the rod through the bearing in the main support and slip a spacer on the rod.

Continue to feed the rod through the next bearing and fit a spacer.

Secure both spacers against the motor support bearing but allow some clearance to allow free movement.

Attach the pendulum ensuring it aligns with the pendulum sensor.

Insert the two clock support tubes.

Slide the PCB support down the two tube with the PCB facing way from the back of the clock.

Connect the motor sensor to MSI

Connect the pendulum sensor to SSI

Connect the motor to Mtr (Red wire) and 5V (Black wire)

Fit the hanging bracket to the upper part of the clock with M2.5 screws.

Slide the clock down on onto the hanging bracket and the lever on Escapement Pt 1 meets with the cup on Escapement Pt2.

Manually check that the escapement still advances the clock.

Attach the USB-C breakout to the left side of the support with 2 x M2 x 8mm self tapping screws and plastic washers to keep the board level.

Connect V+ to 5V and V- to 0V on the PCB.

Step 18: Operation

Apply power via the USB connector.

Setting the Clock

The time can be adjusted at any time when the pendulum is freely swinging.

Simply turn the exposed gear anti clockwise to move the hands to the desired time.

The time can be set prior to the application of power or once power has been applied.

After a short delay the pendulum will be raised to advance the clock and swing freely until the pendulum stops.

After a short delay the process will be repeated.