Introduction: GO BIG OR GO HOME: GIANT LED CLOCK!

If you’ve ever wanted a clock ![]() that doesn’t just tell time but demands attention, this project is for you. I wanted to build something bold, bright, and impossible to ignore—so instead of making a tiny tabletop display, I decided to go big… really big. This Giant LED Clock is designed with oversized 7-segment digits, custom 3D-printed parts, NeoPixel LED strips, and a sturdy MDF frame to hold everything together. This project is a custom 7-segment digital clock built using NeoPixel LEDs

that doesn’t just tell time but demands attention, this project is for you. I wanted to build something bold, bright, and impossible to ignore—so instead of making a tiny tabletop display, I decided to go big… really big. This Giant LED Clock is designed with oversized 7-segment digits, custom 3D-printed parts, NeoPixel LED strips, and a sturdy MDF frame to hold everything together. This project is a custom 7-segment digital clock built using NeoPixel LEDs ![]() controlled by an ESP32, all powered through a stable buck-boost power supply.

controlled by an ESP32, all powered through a stable buck-boost power supply.

To bring the display to life, I 3D-designed each of the seven segments (a, b, c, d, e, f, g) and printed them as individual light modules. Each segment is paired with a white 3D-printed diffuser cover, designed in Autodesk Fusion 360, to create an even and elegant glow from the NeoPixel LEDs inside.

The clock structure combines digital fabrication with classic craftsmanship. The frame and base are made from MDF sheets, cut into four clean pieces to form a sturdy enclosure. Custom 3D-printed corner angles secure the panels together with screws, giving the clock a precise and durable build.

The result is a sleek, modern timepiece that showcases LED lighting![]() , microcontroller programming, and hybrid fabrication techniques—all wrapped into a unique functional design. Whether you’re into electronics, 3D printing, or creative clockmaking, this project brings all those elements together in one bright and stylish build.

, microcontroller programming, and hybrid fabrication techniques—all wrapped into a unique functional design. Whether you’re into electronics, 3D printing, or creative clockmaking, this project brings all those elements together in one bright and stylish build.

Each digit is large enough to be seen across the room, and the diffused LED segments give it the clean, modern look of a commercial display—except this one is fully DIY and completely customizable. From designing the 3D segments, to assembling the power circuit, to programming the ESP32, every part of this build embraces the “go big or go home” spirit. It’s bold, bright, and unapologetically oversized—and that’s exactly the point.

Supplies

Hardware:

- ESP32 - ESP-WROOM-32

- Neopixel LEDs

-

- - 3D printer

- White and Black PLA Filament

- MDF sheet or Cardboard

- Connecting Wires

- Wire Cutter

- Plier

- Scissors, cutter

- Male Jumper Wires

- Solder Iron

- Power cable

- Power Supply 5V Output

- Female Header

- Laser Cutter or Handsaw

- Black Spray Paint

- Measuring tapes

- Markers/pencils

- Double sided tape and Paper tape

- Drill Machine

- Screw driver

- Screws - M3 10mm

- M3 Nuts

Software:

- Arduino IDE v2.3.6

- Autodesk Fusion 360

- Ultimaker CURA (for 3D Printing)

Step 1: Clock Design

This clock ![]() is designed as a fully custom, modern 7-segment digital display built using NeoPixel LEDs

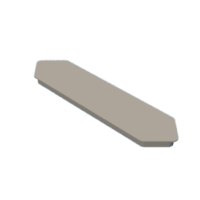

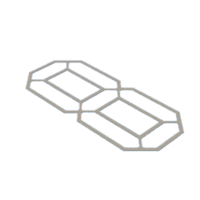

is designed as a fully custom, modern 7-segment digital display built using NeoPixel LEDs ![]() and an ESP32 microcontroller. Each of the seven segments for every digit is individually 3D-designed and printed to form a modular, easy-to-assemble display structure. The segments are shaped to match the traditional 7-segment layout—a, b, c, d, e, f, and g—and each piece is printed in black to minimize light leakage.

and an ESP32 microcontroller. Each of the seven segments for every digit is individually 3D-designed and printed to form a modular, easy-to-assemble display structure. The segments are shaped to match the traditional 7-segment layout—a, b, c, d, e, f, and g—and each piece is printed in black to minimize light leakage.

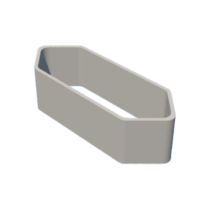

To create a smooth and even illumination effect, every segment is fitted with a 3D-printed white diffusing cover. This cover softens the LED brightness, eliminates hotspots, and gives the clock a clean, professional appearance when lit.

The electronics are driven by an ESP32, which controls the timing, animations, and color effects of the NeoPixel LEDs. Power is supplied through a buck-boost converter, ensuring the LEDs and microcontroller receive a stable voltage regardless of input supply variations.

For the physical enclosure, a frame and base are built from MDF sheet, cut into four pieces to form a rectangular body around the display. These pieces are connected using 3D-printed corner brackets and secured with screws, giving the structure strength and ensuring precise alignment. The combination of MDF and 3D-printed components results in a robust, clean-looking frame that highlights the glowing digital segments.

Overall, the design blends 3D printing, electronics, woodworking, and LED diffusion techniques to create a bright, attractive, and highly customizable digital clock suitable for any workspace or home setting.

Step 2: 3D Printing the Segments

Each of the seven segments—a, b, c, d, e, f, and g—was first designed in Autodesk Fusion 360.

The shapes were modeled to match the proportions of a traditional 7-segment display, with hollow interiors to house the NeoPixel LED strips. Mounting slots and alignment edges were added to ensure that each segment fits together accurately when assembled.

![]() Actions required:

Actions required:

Using the provided 3D design files, start by printing all the segment pieces in black PLA. Black works great because it prevents light from leaking out of the sides and keeps the glow focused through the diffuser.

For the segment sizes:

- The b, c, e, and f segments are all the same size. I used Segment.stl for these.

- The a, g, and d segments are also the same size, but slightly smaller than the others. For these, I used SmallSegment.stl

- For the colon dots (: ), I used a circular piece with a diameter of 29mm, which matches nicely with the digit proportions and the file is dotBody.stl

Feel free to use the same dimensions or tweak them based on how big or small you want your digits to be. Larger digits look impressive but require more LEDs; smaller digits are easier to mount and power.

Each segment also has a matching white diffuser designed to soften the LED brightness and give a clean, uniform glow. Print these diffusers in white or translucent PLA.

Similarly for the diffusers the files are whiteCover.stl and SmallWhiteCover.stl

enclosure

Step 3: Cleaning and Preparing the 3D-Printed Pieces

Once all the parts are fresh off the printer, give them a little cleanup to make everything fit and look perfect. You can go ahead and use any suitable method that you want.

![]() Actions required:

Actions required:

1. Remove Support Material

If any supports were generated during printing, gently remove them using pliers or your fingers. Take your time—PLA can snap if handled roughly.

2. Trim Extra Stringing

Use a precision knife or small scissors to trim any stray strings of filament that may have formed between edges.

3. Light Sanding

Lightly sand the outer edges of the black segments to smooth out any rough surfaces.

For the diffusers, sanding the inner edges helps them fit better. Use:

- 220–400 grit sandpaper

- Gentle pressure (diffusers are thin)

4. Test Fit the Diffusers

Before gluing or pressing anything in place, test-fit each diffuser onto its corresponding black segment.

- If it’s too tight, sand the inner lip a bit.

- If it’s too loose, you can add a tiny drop of hot glue during final assembly.

5. Clean the LED Cavity

Make sure the inner cavity (where the LEDs will be placed) is free from dust or leftover filament. A small paintbrush or air blower works perfectly for this.

6. Final Dust-Off

Before mounting LEDs, give each piece a quick dust-off so nothing blocks the light diffusion later.

Step 4: Base Preperation

I have used the base piece of MDF for assembling the LEDs and and 7-segment pieces.

![]() Actions required:

Actions required:

Start by preparing the base on which the entire clock structure will be mounted. For this project, cut MDF sheet pieces of following sizes

1) 50 × 30 cm (Base of the frame)

2) 51 x 30 cm 2 Units (for top and bottom of frame)

3) 10cm x 30cm 2 Units (For left and right of the frame)

MDF (Medium Density Fiberboard) can be cut using various tools depending on the thickness of the sheet and the tools available to you. I used a rotary cutter to cut both the base and the frame pieces, but if you have access to a laser cutter that supports lengths over 50 cm, that is an excellent option for achieving clean, precise cuts.

![]() Safety Tips!

Safety Tips!

- MDF contains fine particles and resin—always cut it with proper dust extraction.

- Wear a dust mask or respirator, safety glasses, and hearing protection.

- Work outdoors or in a well-ventilated area when possible.

Step 5: Drilling and Spray Paint

![]() Actions required:

Actions required:

Take your 7-segment stencil(we printed in previous section) and begin marking the layout of the four digits on the board. Be sure to measure accurately and maintain consistent spacing between the digits for a balanced and clean appearance. Also mark the positions of the two circular colon dots that will sit between the hour and minute digits.

You can also use the DXF file for the project as a reference to and dimensions to take reference.

Then we can mark Dots using the marker at the end of each segment to drill the hole for the LED wiring, basically there will be two holes for each segment and each dot of the colon (from one the led wire will go in and from one the led wire will come out).

Then use a drill with 3-4mm drill bit to drill the hole at each marked position.

Once this cutting and drilling are done, apply a coat of black spray paint. Spray evenly across the surface to avoid streaks, then allow the paint to fully dry. A smooth, matte-black background helps enhance the visibility of the illuminated 7-segment display.

Step 6: Alternate Base (Optional)

If MDF is not available, feel free to use cardboard. Cutting cardboard is much easy than MDF, no doubt but if you want a sturdy structure for your clock, I would prefer MDF or even plywood of 3 to 4 mm thickness.

And follow the same actions in the step 5.

I have prepared the base of cardboard sheet as well to check if the Clock looks good and if it is functional. So, yes, the cardboard base should also work if you don't want to go the long way.

1) Do the marking for the same dimensions.

2) Black Spray Paint

3) Use the Stencil to do the marking of the digits locations

4) Stick the LED Strips

5) Make the holes for the LEDs (This is a cardboard so you can use scissors or simple screwdriver as well)

Step 7: Preparing the Segments

![]() Actions required:

Actions required:

Start preparing each 3D-printed segment by attaching the white diffuser cover onto the black segment frame. Start by picking up one of your black 3D-printed segments. Make sure the surface is clean and free from any leftover support material or dust.

Next, take the matching white diffuser piece. These diffusers are purposely designed to be slightly larger so they can press-fit tightly onto the segment.

Align the diffuser with the top edge of the black segment frame, making sure it’s straight. Then, gently press it down along the frame, applying even pressure with your fingers. You’ll feel it snap or slide into place as it locks in. Move along the length to ensure all sides are securely seated.

Repeat this process for all your segments. Once done, you’ll have clean, professional-looking LED segments with smooth, even light diffusion—perfect for your giant digital clock.

Step 8: Cover With Parchment Paper (Alternate)

Yes! I tried with parchment paper/butter paper as well, just to see how well it diffuses the light. And works well too! I have also used a different cavity caps for this method that helps to stick paper on the segments. You can do this as well or if you want you can go ahead with the glue gun method and paste the paper in sideways of the segment.

Make sure each diffuser is just a bit larger than the LED cavity on the black segment piece so that it press-fits securely into place.

Step 9: LEDs Preparation

I have used stardom style WS2812B RGB individually addressable Pixel LED Strip. This one needs a 5V power supply adapter and a controller to work.

To create one complete digit of the 7-segment display, we need to prepare LED strips for each segment. Each digit is made up of seven segments, and depending on the size of the digit you choose, the number of LEDs per segment may vary.

In my design, the digit dimensions are 220mm × 90mm, so I selected the following LED counts for each segment:

- 3 segments use 2 LEDs each

- 4 segments use 3 LEDs each

This combination provided the right brightness and coverage for my chosen digit size. If your digit is larger or smaller, you can adjust the number of LEDs accordingly—more LEDs for larger digits, fewer for smaller ones.

Since the clock uses four digits, the total number of LED strips required is:

- 12 strips of 2 LEDs (3 per digit × 4 digits)

- 16 strips of 3 LEDs (4 per digit × 4 digits)

In addition, the clock’s colon (:) between the hour and minute display uses 1 LED for each dot, so you will need two individual LEDs for the colon.

Once your layout is finalized, cut the LED strip into the required lengths using a sharp pair of scissors.

![]() Safety Tips!

Safety Tips!

- Cut Only at Marked Points:

- LED strips have clearly marked cut lines (usually with a scissor icon). Only cut at these points to avoid damaging the internal connections or rendering the LED segment unusable.

- Choose Reverse-Polarity-Protected Strips:

- It’s a good idea to select LED strips that include reverse polarity protection. If the wires are accidentally connected backward, these strips are less likely to get damaged—saving you costly mistakes and time.

Step 10: LEDs Assembly

Since, the strip comes in inbuilt adhesive method, do not worry about sticking them on the base.

![]() Actions required:

Actions required:

Before placing any LEDs, begin by planning the path of data flow across the 7-segment digit. Using a pencil or marker, lightly map out the direction of the data transfer directly on the painted MDF base. This step ensures that all LED strips will be connected in the correct sequence and that the data flows smoothly from one segment to the next. You can refer to the reference images for proper orientation.

For this design, the data will flow in the following order:

g ➡︎ b ➡︎ a ➡︎ f ➡︎ e ➡︎ d ➡︎ c

This sequence is chosen to simplify wiring and maintain a clean layout on the back side.

Next, pay close attention to the DIN (Data In) and DOUT (Data Out) markings on each LED strip. These arrows indicate the direction in which the data can travel. Align each strip so that the DIN of the next segment correctly receives data from the DOUT of the previous one. Begin pasting the LED strips to the base following this exact order.

For best illumination, try to place every LED strip exactly in the center of each 7-segment block. Proper centering ensures even brightness and prevents hotspots or dim edges when the diffusion covers are placed on top.

Start with the first segment by placing the LED strip labeled “g”. This will serve as the starting point of the entire digit, ensuring that data enters the LED chain in the correct order. Make sure to connect both the data line and power wires correctly as you begin this first segment.

Step 11: LEDs Wiring

For each of the InOut terminal - +5V, GND and Din/Dout I have used 3 connecting wires of approximately 5 cm.

![]() Actions required:

Actions required:

Once all the LED strips are positioned on the base in the correct sequence, the next step is to begin soldering the electrical connections between each segment. Every NeoPixel strip includes three terminals:

- 5V (VCC) – for power

- GND – for ground

- DIN / DOUT – for data flow

Start by connecting the DOUT of one segment to the DIN of the next. These connections must follow the exact data flow path you mapped earlier. Using short, flexible wires for these data links keeps the backside of the MDF board clean and prevents clutter. When soldering, aim for joints that are shiny, smooth, and fully bonded to the copper pads. A dull or lumpy solder joint can create poor connections that lead to unpredictable LED flickering or failures. Good soldering now will save you from future troubleshooting.

And don’t worry if it isn’t perfect on the first try—I didn’t get the wiring correct in one go either! I myself did the soldering twice or thrice.![]()

After the data connections are complete, move on to soldering the 5V and GND lines. These can be connected using a power bus, where all segments share a common positive and ground wire. This method ensures consistent brightness across the entire digit and reduces chances of voltage drop.

If you prefer, you can solder all three lines—5V, GND, and Data—at the same time. I also used this approach, and it turned out to be much faster and more efficient. Just make sure to use different colored wires for each connection (for example: red for 5V, blue for GND, and black for Data, like I did). Color-coding your wiring will make it easier to track each connection, especially when you’re working with multiple segments and yes, it looks better.

Once all wires are soldered, verify your work using a multimeter. Check continuity from DIN to DOUT across every segment and confirm that each LED strip is properly connected. This quick test ensures that everything is wired correctly before powering it up with the ESP32 and you won't have to waste time in fixing wiring issues later.

Step 12: Power Circuit Aseembly

Now that your LED segments are wired, it’s time to set up the power system that will keep the ESP32 and all the NeoPixel LEDs running smoothly. LEDs can be a bit picky about their voltage, so a clean and stable power setup makes a huge difference.

![]() Actions required:

Actions required:

1. Mount the Buck-Boost Converter

Start by placing the buck-boost converter on the backside of the MDF base or inside the frame—wherever you find it easiest to access later.

Make sure it’s mounted securely using:

- Double-sided tape, or

- A 3D-printed holder, or

- Small screws (if your module supports it)

This converter ensures the LEDs receive a stable 5V output even if your input voltage fluctuates.

2. Adjust the Output Voltage

Before connecting anything, set the buck-boost converter to the correct voltage.

- Connect the module to your input power source

- Use a multimeter to measure the output

- Turn the adjustment screw slowly until it reads 5.0V

Take your time here—feeding incorrect voltage can damage both the LEDs and the ESP32.

3. Connect Power Lines from the Buck-Boost Converter

Once your output voltage is stable, connect the converter’s 5V and GND lines to your LED power bus.

- 5V Output → 5V Bus Line

- GND Output → Ground Bus Line

Make sure your wires are thick enough (22AWG or similar) to handle the current for all LED strips.

4. Powering the ESP32

Next, power the ESP32 using one of the following methods:

Option A: Direct 5V Input (Recommended)

Connect the same 5V and GND from the converter to the ESP32’s:

- 5V pin

- GND pin

This keeps everything running off one clean power supply.

Option B: USB Power

You can also power the ESP32 via USB, but make sure both the USB ground and LED ground are connected together.

Otherwise, the LEDs may behave unpredictably.

5. Add a Capacitor for Stability (Optional but Recommended)

I have not, but you can!

To avoid sudden current spikes that can reset the ESP32, add a large electrolytic capacitor (around 1000 µF, 6.3V or higher) across the 5V and GND lines near the first LED segment.

6. About the Resistor on the Data Line

You don't have to add an additional resistor, since this LED strip has got an in-built resistor to protect the LEDs from accidental voltage spikes and makes data transfer more reliable.

7. Secure All Connections

Once all wiring looks good:

- Heat-shrink your solder joints

- Bundle wires neatly with masking tape on the back of the frame

- Keep power and data wires separate when possible

A clean layout not only looks better but makes fixing issues much easier later.

8. Final Power Test

Before running any code:

- Double-check voltage with a multimeter

- Confirm all grounds are connected

- Power on the buck-boost converter

- Make sure nothing heats up or smells odd

If everything looks good—you’re ready to plug in the ESP32 and run your first LED test!![]()

Step 13: Understanding the Code

1. As we are using FastLED Library to control the Neopixel LEDs we need to install the FastLED Library

So you need to go to Arduino IDE → Sketch → Include Library → Manage Libraries

Search: "FastLED" then Install

2. Copy Files given below to Your Sketch Folder

Place these three files in the same folder as your `.ino` file:

- `pixelHeader.h`

- `pixelHeader.cpp`

- `pixelClock.ino`

3. Verify Your Hardware

- **LED Strip**: WS2812B or compatible (WS2811, SK6812)

- **Data Pin**: Note which GPIO pin (default example uses pin 5)

- **LED Count**: Count total LEDs in your module

- **Power**: 5V supply, adequate current (60mA per LED at full white)

🔧 Configuration

Basic Configuration (in your .ino file)

Color Configuration

```

Brightness

⚠️ **Start with low brightness** (20-50) to:

- Protect your eyes during testing

- Reduce power consumption

- Extend LED lifespan

Setting the Wifi Credentials

Step 14: Testing

Alright—once all the LED strips are wired, the power circuit is in place, and the ESP32 is connected, it’s time to test everything. This step makes sure your wiring is correct before you fully assemble the clock, so you don’t have to tear things apart later.

![]() Actions required:

Actions required:

1. Do a Quick Visual Check

Before powering anything:

- Make sure no wires are touching or crossing accidentally

- Verify that all solder joints look clean, shiny, and solid

- Check that 5V, GND, DIN, and DOUT wires haven’t been mixed up

- Confirm your power bus lines run correctly to all segments

This is your last chance to catch a loose or ugly solder joint without powering things up.

2. Verify Continuity with a Multimeter

Set your multimeter to continuity mode and do a quick run-through:

- DIN → DOUT: check that each segment passes the signal forward

- 5V line: confirm all segments are connected to the positive bus

- GND line: confirm all grounds are common

- No shorts: check that 5V and GND are NOT accidentally connected

If you hear unexpected beeps between 5V and GND—stop and find the short.

3. Power On the Buck-Boost Converter Alone

Before connecting the LEDs:

- Power the converter

- Confirm the output still reads 5.0V

- Check if anything heats up (it shouldn’t!)

If voltage looks stable, move on.

4. Connect the LED Power Bus

Now plug the LED strips into the 5V and GND lines.

Power up again:

- All LEDs should remain OFF (this is normal)

- If any LED flashes randomly or stays lit, it may mean a wiring issue

If all looks calm, you’re good to proceed.

5. Upload a Simple LED Test Code to ESP32

Use a basic NeoPixel test sketch—like:

- Turn all LEDs red

- Then green

- Then blue

- Then a rainbow sweep

This makes it VERY easy to identify a bad segment.

You don’t need your final clock code yet—just a simple check pattern.

6. Watch the LEDs Carefully

As the test runs, look for:

- A segment that doesn’t light up

- Wrong colors

- Flickering

- LEDs lighting in reverse order

- The signal stopping partway through (common DIN/DOUT mix-up)

If the first few LEDs work but others don’t, it almost always means:

- A bad solder joint

- A reversed DIN/DOUT connection

- A wire broke during bending

Touch these wires lightly—sometimes the behavior changes and reveals the fault.

7. Check Power Stability

While your test animation is running:

- Measure voltage on the first and last LED strip

- It should be close to 5V everywhere

- If the last segment is significantly lower (e.g., 4.5V), add another power injection point

Stable power = stable colors.

8. Stress Test (Optional but Helpful)

Set all LEDs to full white brightness for a few seconds.

This draws maximum current.

Check for:

- Dimming

- Color shift

- ESP32 randomly resetting

- Wires heating up

If everything stays stable—you’re golden.

9. Final Clean-Up

Once the system behaves perfectly:

- Unplug it

- Secure wires with zip ties or hot glue

- Make sure connectors won’t pull loose during assembly

- Install diffusers and frame pieces

And you’re officially ready to move on to the final build!![]()

Step 15: Frame Joints Preperation

![]() Actions required:

Actions required:

In this step, you’ll be assembling the 3D-printed corner brackets that will hold the MDF frame together. Start by taking one of the brackets and locating the small recessed slot designed to hold a nut. Insert the nut into this pocket—make sure it sits flat and properly aligned so the screw can catch the threads.

Next, take a screw and insert it through the hole on the opposite side of the bracket. As you tighten the screw, it will pull the nut securely into place inside the slot. You can tighten it by hand at first and then snug it down with a screwdriver to make sure it’s firm.

Repeat the same process for the remaining brackets. Once assembled, these corner brackets will act as strong connectors that you’ll use later to fasten your MDF frame pieces together cleanly and securely.

Step 16: Final Assembly

![]() Actions required:

Actions required:

In this step, you’ll be running a full-segment test on your LED digits—this is important to confirm that all your wiring, solder joints, and data connections are correct before closing everything up.

To do this, upload a simple test code (like an “all-on” or “88:88” pattern). When the code runs, the ESP32 will send data into the DIN of the first segment, and the signal will travel through each DOUT → DIN connection you soldered earlier.

You should see the display show 88:88 first. This pattern lights up every segment (a–g for all digits plus both colon LEDs). This lets you check:

- All solder joints are connected properly

- No segments are swapped or wired backwards

- The entire data chain is flowing smoothly

- Brightness is even (meaning your 5V and GND rails are stable)

After that, the display will cycle through a few different numbers. This helps you check whether individual segments respond correctly when only certain LEDs are supposed to be lit.

If something looks off—like a dim segment, flicker, or a digit not lighting—this is the perfect time to fix it. It’s much easier now than after assembling the frame.

By the end of this test, once you see all segments light smoothly and consistently, you’ll know your LED wiring is solid and ready for final assembly.

Step 17: Final Assembly Guide

You’ve got all your segments wired, the LEDs tested, and the frame pieces ready — now it’s time to bring everything together into your finished clock.

![]() Actions required:

Actions required:

1. Prepare the MDF Base & Frame

- Make sure the MDF base (50 × 30 cm) is fully dry after painting.

- Align your 3D-printed segments (a to g + colon dots) on the marked outlines.

- Do a quick dry placement:

- Check spacing between digits

- Ensure wires have enough space to route beneath

- Confirm colon dots line up nicely in the center

If everything looks good, move ahead.

2. Mount the 3D Segments

- Take some screws and mount on both corners of the segmenet such that the segment can snug fit on both the screws.

a. Attach the Black Segment Bodies

- Use hot glue or double-sided tape (foam tape works best).

- Press each piece firmly onto the MDF so it doesn’t move while wiring underneath.

b. Insert the Diffusers

- Once LEDs inside each segment are working, snap or press-fit the white diffusers onto each segment.

- If they feel loose, add one tiny drop of glue on a corner only, so you can still remove them in the future.

Your digits will now look like an actual digital clock!

3. Organize and Route the Wiring

- Flip the board to access the underside.

- Bundle the three wires (5V, GND, Data) using:

- Zip ties

- Cable clips

- Hot glue anchors

- Make sure data wires follow the exact flow you planned earlier:

- g → b → a → f → e → d → c → next digit → colon

- Keep 5V and GND running as two neat “power rails” across all digits.

- Label wires if needed — future you will thank you.

4. Mount the ESP32 and Buck/Boost Converter

- Place the ESP32 on the back side of the base using screws or double-sided tape.

- Mount the buck/boost module next to it for short, tidy power connections.

- Connect:

- Buck/boost 5V → LED 5V rail

- GND → LED GND rail

- ESP32 GND → LED GND

- ESP32 Data Pin (D5 or whichever you selected) → First LED DIN

Tip (Optional):

Add a 330Ω resistor to the data line and a 1000 µF capacitor across 5V & GND for extra stability.

5. Closing the Frame

Attach the 3D-printed corner angles to the four MDF frame pieces and screw them together.

Then mount this frame around the base like a picture frame for a clean, finished look.

Now your clock physically looks complete. Time to bring it to life!![]()

Step 18: Troubleshooting Guide

Even in small projects, a lot can go wrong! Even if you follow every step perfectly, LED clocks love to surprise you with tiny issues. And that is why, I have listed down a few troubleshooting points just to be sure that you get it all right in one shot and most common problems can be fixed quickly.

1. Some LEDs Are Not Lighting Up

Possible Causes ![]()

- Wrong DIN/DOUT direction

- A cold/loose solder joint

- A damaged LED at the beginning of a strip

How to Fix ![]()

- Trace the signal path and confirm every strip’s DIN receives data from the previous strip’s DOUT

- Reflow (reheat) any dull or uneven solder joints

- If one LED in a strip is dead, the whole chain after it stops working—replace that section if needed

2. LEDs Light Up But Colors Look Wrong

Possible Causes ![]()

- Incorrect LED type selected in the code (e.g., GRB vs RGB)

- Weak ground connection

- Voltage drop at the far end

How to Fix ![]()

- Check the NEOPIXEL_COLOR_ORDER in the code

- Recheck all GND connections—NeoPixels behave strangely without a solid ground

- Measure voltage at the last LED; if low, add power injection

3. Random Flickering or Glitching

Possible Causes ![]()

- Interference on the data line

- Long wires between segments

- Floating or disconnected GND

How to Fix ![]()

- Add a 330–470Ω resistor to the data line near the first LED

- Keep data wires short and neat

- Make sure ESP32 GND and LED GND are connected firmly

4. Entire Digit Not Working

Possible Causes ![]()

- Power wire to that digit is broken

- DIN at the first segment is not receiving signal

- Misaligned 3D-printed segment causing LED short

How to Fix ![]()

- Check continuity from the power bus to that digit

- Test that the first segment of that digit is getting correct voltage

- Slightly pull on each wire — if one pops off, re-solder

5. ESP32 Keeps Restarting

Possible Causes ![]()

- Power supply cannot handle the current

- Short in wiring

- All LEDs set to full brightness at once (high current spike)

How to Fix ![]()

- Use a buck/boost converter rated for 3A or more

- Reduce brightness in code (strip.setBrightness(80))

- Check for shorts between 5V and GND with multimeter

6. Some Segments Glow Dimly Even When OFF

Possible Causes ![]()

- Stray voltage or wrong grounding

- Data pin set to input instead of output

- Leakage because of very long GND lines

How to Fix ![]()

- Confirm the data pin is initialized properly in setup code

- Strengthen the GND connection

- Add a small capacitor (100–1000 µF) across 5V and GND near the LED input

7. Colon LEDs (:) Not Working

Possible Causes ![]()

- They were wired after the last digit, but didn’t receive correct DOUT

- Incorrect number of LEDs defined in code

How to Fix ![]()

- Verify colon DIN is fed from the last digit’s DOUT

- Update total LED count in the software

- Make sure the colon LED polarity matches the strip direction

8. LEDs Turn ON But Are Very Dim

Possible Causes ![]()

- Diffusers blocking too much light

- Wrong brightness set in code

- Low voltage from power supply

How to Fix ![]()

- Increase brightness carefully

- Re-check voltage at LED input

- Try powering only one digit to see if brightness improves

9. The Test Pattern Runs But Time Display Is Wrong

Possible Causes ![]()

- Incorrect segment mapping in code

- Wrong order of g → b → a → f → e → d → c

- One segment receiving data out-of-order

How to Fix ![]()

- Match each segment ID with the code’s segment list

- Re-check the drawn flow arrows on your base

- Make sure wiring order matches your physical digit layout

10. Nothing Works at All

Possible Causes ![]()

- Main power not reaching the strips

- ESP32 not powered or stuck in boot mode

- Power polarity reversed (common!)

How to Fix ![]()

- Measure 5V and GND right at the first LED

- Make sure ESP32 is connected to correct input

- Double-check polarity at every joint

Step 19: Final Programming & Display Calibration

![]() Actions required:

Actions required:

Start loading the finished clock code onto the ESP32 and verifying that everything works exactly as expected. Start by connecting your ESP32 to your laptop via USB. Open your Arduino IDE or preferred coding environment and upload the final program that handles timekeeping, LED updates, brightness control, and colon blinking.

Once the code is uploaded, place the clock in a dark or dim environment to clearly see how each segment illuminates. Check the digits on the physical clock while referencing your design files or simulation on the screen. Ensure the numbers are properly aligned, all segments light evenly, and no LEDs flicker or misbehave.

If needed, make small adjustments in the code—such as brightness, animation timing, or segment mapping—and reupload until your display looks crisp and accurate. This step ensures your giant LED clock is fully calibrated and ready for everyday use.

Step 20: The Result

![]() No further Actions required

No further Actions required ![]() :

:

The final build works exactly as intended: the 7-segment digital clock lights up with bright, evenly-diffused LEDs, and all four digits update smoothly in real time. The white diffusers give each segment a clean, professional look, and the colon LEDs sync perfectly with the main display. Thanks to the stable 5V power circuit and the correct DIN→DOUT wiring sequence, the animations run without flicker, lag, or brightness drops. Overall, the clock is solid, accurate, visually appealing, and ready for everyday use.![]()

If you face any difficulties in executing the project do comment below, I would love to help you out.![]()