Introduction: Heirloom Chest

This project is going to be fairly detailed on a number of fronts.

- The Design

- The Build

- Engraving Letters

- The Finish

Hope you are able to get something out of this and I'd love to see what you build.

Let's begin.

Step 1: The Design

For this project, the client wanted a chest that can hold memories and be passed down through the family. With this in mind, it needs to be built to stand the test of time. ...and rowdy children.

I started out with a couple drawings and sent them to the client. One with legs and the other as a simple box. They chose the latter. Either design was fine with me because I didn't draw something, or really give an option on something I didn't think I would enjoy building.

They wanted this to be at the foot of their bed so I based most of my measurements on that. Then I went on to drawing up the construction and material breakdown. I used knotty pine as the material for a couple of reasons: Their budget and to assist in the appearance they were looking for.

Step 2: The Build

I built the chest walls a panel at a time. Each panel would consist of a top and bottom piece with grooves cut and slats with tenons to fit.

With solid wood, you need to factor in wood expansion. Through the seasons, wood has a tendency to shrink and expand in the summer, winter and rainy seasons. Yes, even inside your house. There's no getting around this unless you use plywood. But in our case, we're using solid wood and need to allow for the movement.

Here's how:

- The tenons are cut to be snug in the grooves. Not super tight, but enough that they won't rattle around.

- I left them unglued. This way, they can slide a bit if they need to. If I glued them down and they shrank, they could split the wood. I want this thing to look aged, but not break over time.

- I left 1/32" gaps between the slats. This gave the wood room to move. Wood is strong and alive. You can strap it down all you want and it still has the possibility to push things apart.

To attach the end pieces, I used my biscuit jointer. It's perfect for things like this since gluing things to the end grain isn't structurally sound.

Once the panels were built, I went ahead and finished the inside with a dark walnut danish oil. As much as you can do to finish your cabinet before you put it together, do it!

This oil doesn't take long to dry, so assembly happened soon after I applied the inside finish. Because I was planning to paint this piece, butt joints will do just fine. The joint is also long grain on long grain so glue and brad nails will make for a strong joint. Technically, the glue will outlast the nails.

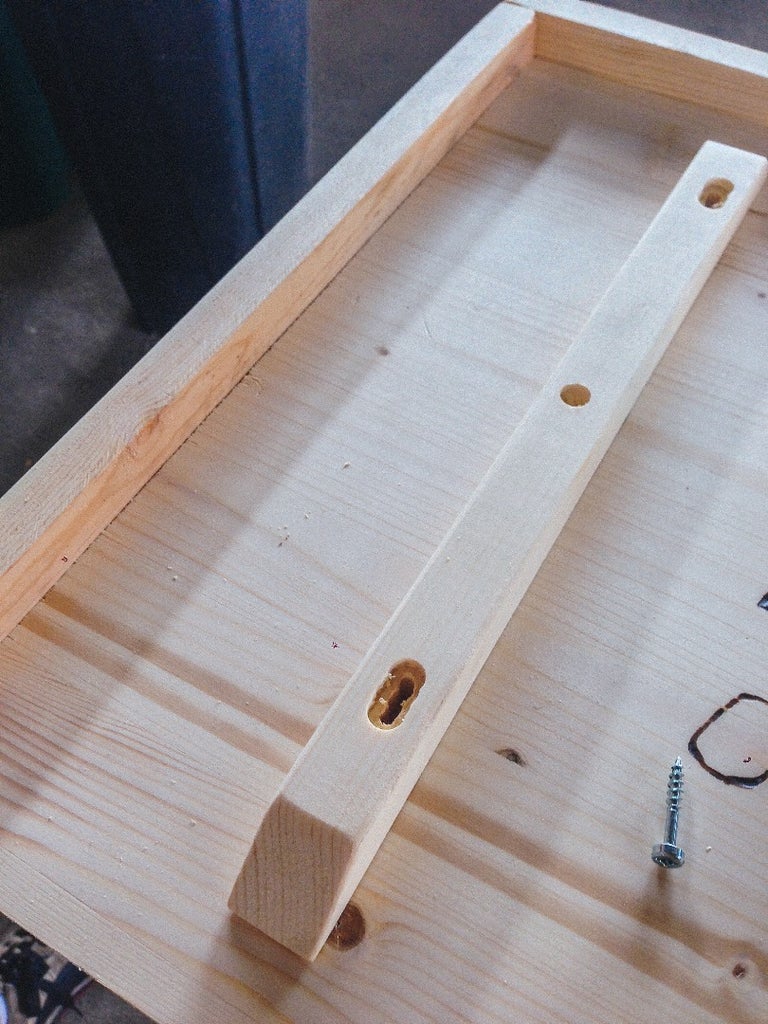

For the top, I laminated several pieces together for one large board. I did this so I could engrave their names in the top later. To keep the laminated pieces straight over time, I added 2 support runners underneath with slots to allow for wood expansion.

Now to apply the trim and make the top. I placed the top on top and that all told me where the trim would lie.

Step 3: Engraving

For the top, I engraved their name. They wanted their last name and the word legacy written under it. You'll see a larger view of that in the Finishing Step. Not sure why I don't have a natural finish shot of it. Oh well. I made a layout in Photoshop and printed it out for a stencil and gently used my router. This was a nerve-wracking thing to do since this was the most visible piece of the chest.

Under the lid, they wanted their kids names and birthdates written. I penciled everything and etched that with my wood burner. You can see the burning in the cover image of this project.

Step 4: The Finish

For the worn look, I layered three different finishes to be sanded through.

First, I stained the piece dark. This made the trunk look like crap. Luckily, this is just the undercoat.

Over the stain, I used milk paints. Milk painting is one of the oldest forms of painting. You can achieve a completely perfect finish or a rough, spotty, textury finish. It's all in how you mix and apply it. I went for a fairly smooth finish knowing that I'd sand through it.

The first coat of milk paint was a really light gray.

You don't have to be perfect here since it's just the middle coat. It was also a good chance to practice as I had never used this stuff before. It also dries super quick. A soon as I was done walking around the piece to apply the first coat, it was already dry where I started.

Now to the next coat. I went fairly dark and added a tiny bit of blue to it.

The next morning, I went out with 150 grit sand paper and wore the piece out. Some question what method you go through to wear a piece out. I typically only sand places that would have been touched the most over the years. Around handles, lid, corners and other places that stick out.

As you can see, I have 3 layers that I can reveal to. It adds a lot of depth to the piece.

Step 5: The Hardware

The top was fairly tricky to attach to the piano hinge. Once I got a couple screws in, I was good to go. I drilled pilot holes since I was so close to the edge, I didn't want to split the wood. I used my 'yankee drill' for this. They are perfect for this.

To keep the lid from flopping all over, I bought a lid bracket that keeps the lid from swinging too far back. It add's a seriousness to the piece, in my opinion.

Step 6: The Finish

I did a couple coats of water based polyurethane. I really like this stuff because of the fast drying time. It was perfect for this piece. Over that, I waxed it.

Hope you enjoyed seeing the progress!