Introduction: Inside the Machine: a Digital Animation

"Hi everyone. For this contest, I decided to create a digital sculpture rather than a physical one. I built a highly detailed 3D model of a standard 12V DC motor and created an animation where it 'explodes' in mid-air to reveal its internal parts.

In this project, I will walk you through my entire process from modeling the copper windings to animating the explosion. I’ll also briefly explain what each component actually does inside the motor, combining my background in electrical engineering with digital art."

I disassembled motors to study how the rotor, stator, and brushes fit together. This research phase was crucial to ensure that my digital model would be mechanically accurate.

Before I modeled this 12V motor, I wanted to understand its Timeline. The device we use today to power everything from toys to robots didn't just appear; it is the result of 200 years of scientific curiosity.

The story of the electric motor is the story of humans mastering the invisible force of magnetism. It began in 1821, when Michael Faraday dipped a wire into a pool of mercury and watched it spin around a magnet, the first time humanity successfully converted electricity into motion.

1821 (The Discovery): Michael Faraday demonstrates the principle of electromagnetic rotation.

1832 (The First Commutator): William Sturgeon invents the first DC electric motor capable of turning machinery.

1834 (The Patent): Thomas Davenport builds the first real battery powered electric motor used to run a model train.

1873 (The Industrial Age): Zénobe Gramme demonstrates that the motor is reversible (it can be a generator too), kickstarting the modern industrial revolution.

2025 (The Digital Era): Today, I am using Fusion 360 to digitally deconstruct this 19th-century invention, revealing the enduring beauty of its design."😊

Wikipedia, Timeline of the electric motor: https://en.wikipedia.org/wiki/Timeline_of_the_electric_motor

Fusion: https://a360.co/44bUMbA

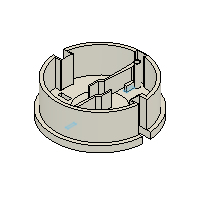

motor

Supplies

To bring the concept to life, I relied on three core supplies

- 12V DC Motor: "This was my primary reference. I needed the real object in hand to check angles, clearances, and the exact dimensions of components that are often missing from standard datasheets."

- Digital Vernier Caliper: "This tool was essential for precision. I used the caliper to measure every single part, the shaft diameter, the thickness of the housing, and the width of the magnets ensuring the digital model was a perfect mechanical replica."

- PC with Fusion 360: "This was the digital studio. Fusion 360 allowed me to model the geometry parametrically, but more importantly, it let me choreograph the animation and generate the final cinematic renders."

Step 1: Measuring and Reverse Engineering

Before opening Fusion 360, I needed a plan. I took the physical 12V motor and measured every critical dimension using the digital vernier calipers.

I measured the shaft diameter, the outer casing length, and the distance between the mounting holes. I sketched a rough diagram in my notebook and noted down all these values. Creating this 'cheat sheet' first was important, it meant that once I started 3D modeling, I could just type in the numbers without having to stop and measure the motor every two minutes.

Step 2: Designing the Main Body (The Stator)

With my measurements ready, I opened Fusion 360 to start the actual modeling. I began with the Stator, which is the stationary outer shell of the motor.

I started by sketching a simple circle on the ground plane using the exact diameter I measured earlier. I used the Extrude tool to pull that circle up into a cylinder, creating the main housing.

1. The Base Sketch: First, I selected the top plane in Fusion 360 and drew a 2D circle. I input the exact diameter from my caliper measurements to ensure scale accuracy.

2. The Extrusion: I used the Extrude tool to turn that 2D circle into a 3D cylinder. By pulling the arrow upwards, I gave the motor its length. This created the solid block of material that would become the housing.

3. Cutting the Details: A real motor isn't just a solid cylinder; it has screw holes and ventilation slots.

- I selected the top face of the cylinder and created a new sketch.

- I drew small circles for the mounting screw holes and rectangular shapes for the cooling vents.

- I selected these new profiles and used the Extrude command again, but this time I switched the operation from 'Join' to 'Cut'.

This subtracted the material from the solid body, creating perfect holes and vents. I repeated this 'Sketch-Extrude-Cut' process to carve out the inside of the cylinder, creating the hollow space where the rotor would eventually sit."

Step 3: The Rear Enclosure and Brushes

Once the metal body was finished, I moved to the back of the motor—the Rear Enclosure. In the real world, this is a plastic cap that holds the electrical terminals.

I modeled this part to fit snugly into the back of the steel case, adding the two small metal tabs where wires would normally connect.

The Challenge of the Brushes: Inside this plastic cap sit the 'Brushes' the tiny copper brushes that transfer electricity to the spinning shaft. This is an incredibly complex mechanism with tiny springs and copper shunts. I realized that modeling every microscopic detail here would make the mesh too messy.

Instead, I decided to make a creative adaptation. I slightly simplified the brush mechanism in the 3D model. I focused on capturing the look and location of the brushes rather than perfect mechanical accuracy

Step 4: The Rotor, the Coils, and the Commutator

Next, I moved to the heart of the machine: the spinning Rotor. This was the most complex part of the modeling process because it combines structural steel with organic copper shapes.

1. Modelling the Armature (The Core): I started by modelling the central shaft. Then, I sketched the profile of a single metal 'limb' (or pole) of the armature. Instead of drawing every single one manually, I used a smart workflow: I modelled just one, then used the with rectangular array to duplicate it. This created the perfect, gear-like geometry of the iron core.

2. The Copper Windings (The Visual Highlight): To visualize the copper wires, I didn't want a simple block texture. I sketched an Elliptical Path winding around the armature poles. I then used the Pipe command in Fusion 360 to follow that path. This turned the 2D line into a 3D solid tube, making it look like a thick bundle of real copper wire wound tight around the core.

3. The Commutator: Finally, I placed the Commutator on the front of the shaft. This is the segmented copper ring that sits just behind the brushes.

I want to highlight why these parts matter.

- The Rotor/Coils: When electricity flows through these copper 'pipes,' the rotor becomes a temporary magnet (an electromagnet).

- The Commutator: This is the clever 'switch.' As the rotor spins, the commutator physically rubs against the brushes. Every time it turns half a circle, it reverses the direction of the electricity. This reversal flips the magnetic field, pushing the rotor away from the outer magnets and keeping the motor spinning endlessly. Without this part, the motor would just get stuck!"

Step 5: The Permanent Magnets

ith the rotor and casing done, I was missing one vital component: the Permanent Magnets. In a DC motor, these aren't just flat fridge magnets; they are curved to fit perfectly inside the round casing.

1. Modeling the Shape: I went back to the main Stator body. On the inside face, I sketched two curved profiles (arcs) opposite each other. I used the Extrude tool to pull these shapes out, creating two solid, curved plates that line the inside of the steel shell. I made sure to leave a tiny 'air gap' between these magnets and the rotor—if they touched in the model, it would look like a manufacturing error!

How It Actually Works: These magnets are the 'pushers.'

- The Rotor (which we made in the last step) creates a magnetic field that changes constantly.

- These Permanent Magnets create a magnetic field that stays still (Static Field).

- The Magic: Because the Rotor is always switching its polarity (thanks to the commutator), it is constantly being repelled by these permanent magnets. It tries to push away, which forces it to spin. Without these two curved magnets, the rotor would just sit there, buzzing and getting hot."

Step 6: The Art of Rendering

Once the modeling was complete, I moved to the Render Workspace. This is where the project shifts from engineering to art. A grey 3D model is just data; a render is an emotion. I didn't just hit the 'capture' button; I carefully tuned the settings to create a cinematic look.

1. The Materials (Textures): I applied physical textures to every component to make them feel real.

- For the Housing: I used 'Satin Steel' but increased the Roughness slider slightly. Perfect metal looks fake; adding a bit of roughness makes it look used and industrial.

- For the Windings: I used 'Polished Copper.' I wanted these to be the star of the show, so I made them slightly reflective to balance the light reflection.

2. The Environment (The Lighting): I stepped away from the default white background, which looks like a textbook diagram.

- Background: I changed the color to creates 'Chiaroscuro' (high contrast), making the bright copper coils pop against the darkness.

- Lighting: I used a This places the light source behind the object, creating a glowing outline around the metal edges.

3. The Camera Settings: To make the image look like a photograph, I enabled Depth of Field.

- Focus: I clicked specifically on the Copper Commutator to keep it sharp.

- Blur: I set the blur (F-stop) so that the back of the motor is slightly out of focus. This guides the viewer's eye exactly where I want them to look.

Step 7: Bringing It to Life (The Animation)

This was the most challenging part of the project because it was my first time ever using the Animation Workspace in Fusion 360.

1. The Learning Curve: Since I was new to this, I spent time watching 'The Fusion Essentials' YouTube channel tutorials to understand the basics. I learned that animation isn't just about moving parts; it’s about timing.

2. The Explosion Strategy: I used the 'Transform Components' tool to manually grab each part of the motor.

- I didn't use the automatic 'Auto-Explode' button because it looked too messy.

- Instead, I manually pulled the Stator Housing to the left and the Rotor Shaft to the right along the y-axis.

- I dragged the End Cap, rotor and magnets.

3. The Timeline: The secret was in the timeline at the side of the screen. I adjusted the bars so that the End cap moves first, and then just a split second later—the rotor and magnet float out. This slight delay (staggering) made the animation feel elegant, rather than just snapping apart instantly."

Step 8: The Result

Here the scene; Suddenly, the machine opens up. The internal components—the plastic enclosure, the curved magnets, and the complex rotor—slide out smoothly along the Y-axis. It looks as if the motor is being "gutted," leaving the hollow shell behind.

the internal mechanism hovers outside its casing, allowing the viewer to inspect the delicate parts usually hidden by steel.

Thank you for taking the time to view my project

Since this is my very first attempt at creating an animation in Fusion 360, I am still learning the ropes of digital art. I tried my best to make the "Exploded View" look as cinematic and mechanically accurate as possible, but I know there is always room for improvement.

If you enjoyed this fusion of Engineering, I would really appreciate your votes❤️