Introduction: LED Egg Night Light

There's no better weapon against the monsters under the bed than a night light.

And there's no cuter night light than an egg shaped one! Follow along with me as I show you how to model and make a 3D printed LED Egg Night Light of your very own!

To design/model this project, I used Tinkercad– a FREE browser-based 3D modeling program by Autodesk – which is very simple to use, even if you're a complete newbie!

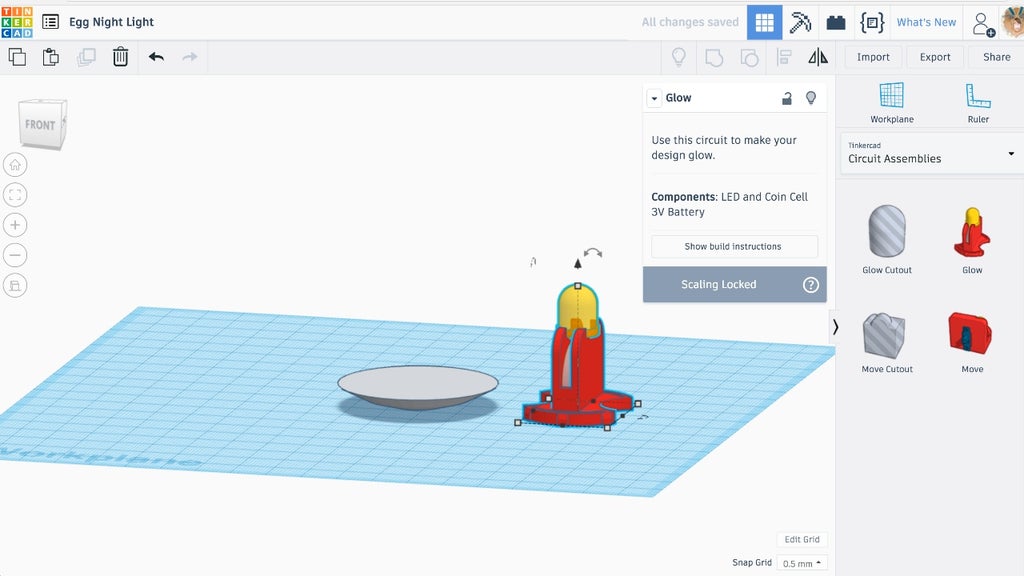

Tinkercad recently added two Circuit Assemblies to their shape menu offerings, one of which is the Glow Assembly, a plug-and-play LED circuit shape that I used to make my Egg shine bright.

NOTE: I won't be covering Tinkercad navigation tools or program functions in this instructable. If you're completely new to the program and either don't know where to start, or are having trouble following along, have a quick read through Lesson 2 of my co-worker JON-A-TRON's Easy 3D Printing Class. It covers everything you need to know to get started from scratch in Tinkercad!

Step 1: Supplies

Before we dive into modeling our night light, I'm going to go over the supplies and tools you'll need to make a physical, finished project.

3D PRINTING TOOLS

You can absolutely follow along with this project without actually 3D printing anything or making the LED Glow circuit (i.e.: you can just do the 3D modeling part), but if you do want to end up with a physical version of the night light, here are the tools and supplies you'll need in order to make it.

- 3D Printer*

- PLA filament that matches your printer

- Wide painter's tape

- Credit card for smoothing out the tape on the print surface

- Rubbing alcohol or an alcohol based lens cleaner

- Sharp chisel (optional)

*To read a great overview of good quality hobby 3D printers – and to find info on where to have your pieces printed if you don't own, or want to own, a 3D printer – read through lesson 1 of JON-A-TRON's Easy 3D Printing Class!

ASSEMBLY TOOL & SUPPLIES

The Glow Assembly was designed to be easy to put together. (Nice work Tinkercad team!) So easy in fact, that you only need 1 simple tool for that (wire cutters) and two other things for egg assembly:

- Wire cutters

- Super glue or E6000 adhesive

- Exacto knife or box cutter blade (not pictured)

GLOW ELECTRONIC COMPONENTS

The parts you need to make ONE Glow circuit assembly are:

- (x1) 3V coin cell battery - ($1.95)

- (x1) 10mm LED - ($0.50)

TOTAL COST (before tax & shipping): $2.45*

*Sparkfun prices subject to change over time.

Tinkercad has made it super convenient to shop for the electronic parts for the Glow Assembly by creating a Glow SparkFun cart that has both parts needed already in it. Their cart includes a yellow LED. If you'd like to swap out or add a different color to your cart (I used a white one for maximum egg-ness), I've provided the SparkFun links below:

IMPORTANT: Coin cell batteries can cause serious injury if swallowed. Keep coin cell batteries out of reach of small children!

Step 2: Sign in to Tinkercad and Create New Design

Go to the Tinkercad website and sign in if you already have an account, or sign up if you don't.

Once you're signed in, click on create CREATE NEW DESIGN to generate a new project workplane.

The page will come already named with funny made up words. Highlight the name by clicking on the words and change it to something project related, like Egg Night Light.

Now we're ready to model our project!

Step 3: Resizing & Dividing the Egg

At the beginning of each 3D modeling step, I've included a soundless how-to video for you to follow along with. I've also included still images below each video that break down the process.

In this step, I show you how to best cut the egg into the two parts we need to make the night light.

Ok, let's make a thing!

- Click on the SHAPES dropdown menu on the right hand side of the screen.

- Click on EXTRAS.

- From the EXTRAS menu, click and drag an EGG shape onto the workplane.

- Resize the egg to be 80mm x 80mm by selecting the egg, holding shift, and clicking and dragging one of the corner white boxes OR by typing 80 into the white length and width dimension boxes.

- Go back to the BASIC SHAPES menu and drag a BOX onto the workplane.

- Make the height of the BOX 6.5mm.

- Switch to a TOP view and ORTHOGRAPHIC (bottom circle in lefthand menu) perspective.

- Resize the BOX so that the length and width are big enough to cover the entire egg, like pictured.

- Go to the FRONT view.

- Select both the egg and the box.

- DUPLICATE both shapes by clicking on the icon that looks like multiple layers of paper in the top left corner of the screen.

- Hold down SHIFT, click on the egg and drag the duplicates to the left of the originals.

- Select the box on the right and make it a HOLE.

- Select both the right egg and box and GROUP them.

This action removes the bottom part of the egg that was covered by the BOX HOLE.

- Next, click and drag a NEW WORKPLANE from the top right corner of the screen (next to the Ruler) and place it on top of the remaining box on the left (This allows any new shapes brought onto the workplane to sit exactly on top of the box shape).

- To get rid of the temporary workplane, click on the white space that surrounds the egg on the right (where the original workplane should be, and will be again).

- Resize the new BOX so that it completely covers the rest of the left egg.

- Select the lower box (the one that is 6.5mm high) and DELETE it.

- Make the remaining box a HOLE.

- Select both the left egg and the box hole and GROUP them.

You will be left with just a little bottom bit of the egg that matches up with the top part of the other egg!

Step 4: Shelling the Egg 'Shade': Part 1

This video segment will show you how to SHELL the egg top so that you end up with a very thin 3D printed wall that the inner LED will be able to shine/glow through. We will also add some extra material thickness to the bottom of the egg top to accommodate the GLOW CUTOUT (the hole that the Glow LED holder will press fit into).

- Move the egg bottom off the workplane.

- Lower the egg top so that it's sitting on the workplane.

- Select the egg top and DUPLICATE it.

- Hold SHIFT and resize the duplicated egg to 77mm x 77mm.

Remember that a duplicated shape will layer itself right on top of the original, but don't worry, it's the duplicate's dimension boxes that are highlighted after duplication.

- Select the outside (original) egg top and make it TRANSPARENT. Doing this will allow you to see how the inner and outer egg tops are aligned.

- Select both the inner and outer egg tops.

- Click on ALIGN, which is the 'line with two boxes to its right' icon in the upper right hand corner of the workplane screen.

- Click on the middle black dot in all three directions. This will center the inner egg top within the outer.

- Highlight the inner egg top only by selecting both, holding down SHIFT, and then clicking on the outer egg – which will deselect it – leaving the inner egg top still selected.

- Make the inner egg top a HOLE.

- Next, bring a CYLINDER shape onto the workplane from the BASIC SHAPES menu.

- Resize the cylinder so that it's 36.5 x 36.5 x 4mm.

- Bring a GLOW CUTOUT onto the workplane from the CIRCUIT ASSEMBLIES menu.

- Select all three shapes and click on ALIGN.

- Click on the middle black dots of the WIDTH and LENGTH only, and NOT THE HEIGHT.

Step 5: Shelling the Egg 'Shade': Part 2

In this step, we'll finish shelling the egg top – before moving onto building the egg bottom and the legs.

- Select both the inner and outer egg tops and then GROUP them.

This creates negative space inside the egg top and 1.5mm thick (thin) wall that is the perfect thinness for the LED light to shine through!

This is what your grouped egg top, or 'shade', will look like (when transparent).

- Select the egg top and un-click Transparent.

Congrats! You have finished the egg 'shade'! Now on to the bottom and legs...

Step 6: Importing and Adding the Move Assembly

In this short step, we will add a MOVE ASSEMBLY that will hold the battery and LED to the egg bottom.

- Move the egg top off the workplane and the egg bottom onto it.

- Go to the CIRCUIT ASSEMBLIES menu and drag a GLOW holder onto the workplane.

You'll notice that a sub-menu pops up with more info when the GLOW shape is selected. An important thing to note is that the SCALING IS LOCKED on both the holder and the cutout. What this means is that you can move them up and down and all around, but you can't resize them.

This restriction is in place because specific, real life, electronic components need to fit into the holder, once printed, and the holder needs to fit into that specific sized hole that we used the GLOW CUTOUT to create in the egg top/shade.

- Select both the egg bottom and the Glow holder.

- ALIGN them by clicking on the middle black dots on both the width and length sides (not the height).

- Select the GLOW holder and raise it 6.5mm off the workplane so that it is sitting atop the egg bottom.

- Select both the holder and the egg bottom and click on GROUP.

- Rotate the newly combines shapes 90° so that the '+' sign on the holder is facing you.

Step 7: Making the Legs

Now, we will make the legs for our night light.

- Move the holder off to the side of the workplane.

- From the EXTRAS shape menu, drag in one CHICK FOOT resize it to be 37.07mm wide x 41mm long.

- Duplicate the newly enlarged foot and drag it to the right while holding SHIFT.

- Go to the TOP view and rotate the left foot -22° and the right foot 22°.

- Rove the right foot towards the left until they overlap about .4mm (like pictured).

- Select both feet and GROUP them, so that they become one piece.

Step 8: Making a HOLE Version of the Legs

In order to make the leg holes in the egg bottom piece, we need to make another set of legs that have a slightly larger diameter in order to create a good tolerance fit for the printed ones.

- Drag a CYLINDER onto the workplane from the BASIC SHAPES menu.

- Resize the cylinder to 4.75 x 4.75 x 12mm.

- Move the small cylinder to the top of the left leg and duplicate it, moving the new one to the top of the right.

- Go to the TOP view and turn the SNAP GRID off.

- Zoom in and place the cylinders so that they are centered on each leg.

- Select the legs and cylinders and DUPLICATE them.

- Move the duplicate set to the side.

- Select the legs and cylinders of the original set and GROUP them, making them one piece.

Step 9: Adding Leg Holes to the Egg Bottom

Now we'll use the grouped legs to create the holes in the underside of the egg bottom.

- Select the egg bottom/holder and it TRANSPARENT.

- Then raise it up and move it so that it's sitting on top of the legs, with the top of the legs ALMOST meeting the line where the egg bottom and GLOW holder are joined.

- Select the legs and the egg bottom/holder and ALIGN them, by clicking on the middle black dots on the width and length sides only, NOT the height.

- Make the legs a HOLE.

- Select the egg bottom/holder and un-click TRANSPARENT.

- Select both the legs HOLE and the egg bottom/holder and click on GROUP. This will create holes in the bottom of the 3D printed egg holder that the printed set of legs will fit into.

Step 10: Checking Your Work

This is a quick step! We'll remove the added cylinders from the remaining leg set and line all the parts up to make sure that everything is going to fit together nicely once printed.

- Select the egg top/shade, egg bottom/holder, and legs.

- ALIGN them by clicking the black dots in the middle of the width and length. DO NOT align the height.

- Select the egg top/shade and raise it up until it is sitting on top of the egg bottom.

- Make both egg parts TRANSPARENT so you can see how the parts are aligning.

- If you're satisfied, un-click TRANSPARENT on both egg parts in anticipation of exporting them for printing.

Step 11: Export Your EGG Files for 3D Printing

Now that you have your parts modeled, it's time to start exporting them as STL files. These STL files will be used to generate your 3D prints! There's one more thing we need to do to the legs to prep them for successful 3D printing, so we'll start by exporting the egg parts.

- Select one egg part at a time, in this case the egg top/shade and click EXPORT.

- Click on the STL button.

- Repeat for the remaining egg bottom part.

Step 12: One More Step for Leg Printing Success!

3D printers don't love printing tall thin objects. To help them with this, it's best to build a thin wall, that is slightly taller than the object, around these kinds of shapes to help keep the filament flowing. Because the legs are so thin and spindly, I highly recommend doing this for this part.

Here's how it's done!

- Move the egg parts that you've already exported off the workplane.

- Drag in a CYLINDER from the BASIC SHAPES menu.

- Make it TRANSPARENT and switch to the TOP view.

- Resize the cylinder to encircle the legs, leaving at least 0.3mm space between the cylinder and the legs.

- Make the height of the cylinder a bit taller than the legs.

- DUPLICATE the cylinder.

- Resize the duplicate to be 4mm smaller and taller than the original.

- From a TOP view, adjust the size of the duplicate so that it creates an even wall thickness between the two cylinders.

- ALIGN the two cylinders.

- Select both cylinders and GROUP them.

Now you're left with a thin wall all the way around your legs.

- Select the wall and un-click TRANSPARENT.

Now it's time to export the legs, along with the wall, as an STL file.

- Select both the legs and the wall.

- Click EXPORT.

- Click the STL button.

And that's it!! You have finished creating your part files in Tinkercad. Congratulations!!!

Next up, 3D printing... :D

Step 13: Print Your Parts!

Now it's time to 3D print your parts!

Print the two egg parts at: 20% fill and the legs at: 100% fill –and BOTH with RAFTS. Do not include supports.

If you've never 3D printed before, read through Lessons 3 & 4 of my co-worker JON-A-TRON's free Easy 3D Printing class. He takes you step-by-step through the process of slicing and printing.

IMPORTANT: The legs are strong, but can snap apart if you try to remove the print from the print bed using the legs. Instead, use a sharp blade to gently ease them off the surface.

Step 14: Putting It All Together!

Now that you have all your parts printed and the circuit parts (coin cell battery & LED) have arrived from SparkFun, it's time to put everything together!

REMEMBER: You'll need some super glue or e6000 adhesive and a sharp blade (exacto knife or box cutter) for this step.

- CAREFULLY, use a sharp blade to clean out any material that is keeping the holes on the egg bottom from a perfect circle. Ask a parent or teacher for help if you aren't comfortable using a blade.

- Try putting the legs in the holes. If they don't fit, keep using the blade to remove a little material at a time until they do.

The GLOW CUTOUT was designed to provide a tight press fit for the GLOW holder. For this application, it's important that the egg top/shade be easy to take off and put back on, so we'll need to shave down the CUTOUT hole a bit.

- Very carefully, use a sharp blade to remove a small amount of material all around the opening in the egg top.

- Repeat this process until the egg bottom/holder goes in and holds in place, but is easy to remove.

- Leave the two egg parts together.

- Add a small amount of glue/adhesive to each leg hole on the egg bottom.

- Press the legs into place.

- Quickly, before the glue dries, place the completed shape on the table and check that the alignment of the legs is correct from all angles. The egg should be straight up and down.

- Let the glue dry.

- Then remove the now glued together leg/egg bottom combo.

- Place the coin cell battery in the holder with the POSITIVE (+) side of the battery facing the same way as the '+' sign on the holder.

- Use your wire cutters to trim about 1/2" off of each LED pin, making sure to keep the length differences.

NOTE: The longer pin is POSITIVE (+), the shorter one NEGATIVE (-) and the difference in pin lengths is how you know which is which.

- Insert the LED into the holder, with the longer POSITIVE (+) pin going in the side of the holder with the '+'.

If you've done it right, the LED should light up!

The only thing left to do is put the top/shade on and get busy scaring away the closet monsters!!

The powers of the Egg Night light are not limited to bedrooms. Use them to add a bit of cute ambiance to any night time setting!

Step 15: Psssst.....

If you'd like to have your own night light, but don't want to go through the process of modeling your own, here are the downloadable STL files for your 3D printing pleasure!

Step 16: Where to Go From Here?

If you've enjoyed this project and would like to learn more about the Tinkercad Circuit Assemblies, including the MOVE ASSEMBLY (a holder that contains a coin cell battery, small vibrating motor, and switch), check out my FREE 3D Printing with Circuits Class!

Happy making everyone and be sure to add photos to the comments section if you make your own LED Egg Night Light!

- Paige

Participated in the

Plastics Contest