Introduction: LM386 Tube Amp [homage]

I recently built the Bike Tyre Speaker and it really needed a little LM386 mono amp to boost the sound, as I wanted to 'Play It Loud'!

My fascination with electronics started from dissecting old electrical equipment just to see what was inside...

...beauty and intrigue...

...what are those bits...

...I started to learn how to put my own electronics together, building a LM386 amp as my second electronics project.

It really is a great little circuit for beginners to try.

For this project I wanted to capture some of that beauty within and what better than the vacuum tube as an embodiment of seeing the 'working' inside...

...the glorification of the humble into an aesthetic beauty.

This humble little amp build takes the aesthetic qualities of the vacuum amp to make an intriguing little object that is...

...great to look at, glowing red when switched on like a vacuum tube...

...the power source on show and easy to get to...

...and the on / volume knob made with a found object, an old bike derailleur jockey wheel to materially tie the amp to the Bike Tyre Speaker.

The two projects are made for each other!

Unfortunately the sound from an LM386 amp will never match the rich + warm tones of a vacuum tube amp, though if you ask me, if it looks this good, it makes it sound good as well!

Step 1: Design

My initial concept sketch caught the essence of the amp...

...a sweet little thing that would look great sitting on a display shelf just begging to be used.

The base of the amp to be a block of wood...

...a battery upturned and slotted in, to give prominence to this rarely thought about part of electronic equipment and easy to get to...

...an upturned spice jar to house the electronic circuit, a simulacra of a vacuum tube...

...that would protect and glorify the mighty LM386 amp circuit...

...an old mountain bike jockey wheel that I had kicking around that felt good in the hand...

...and two audio sockets, one at each end. The position of these would be changed due to space limitations within.

I have added the actual built sizes to the drawing of 55mm wide x 165mm long x 40mm high.

I would suggest that you test the layout and sizes before starting based on the parts and components that you have.

Step 2: Bits + Pieces

There are a number of different parts to this project and I have split the materials into the differing parts.

As many as possible of the materials are scrap or re-used.

BASE

Birch ply strips approximately 50x175mm in size to make a width of just over 55mm = 7x9mm or 5x12mm thick

Old glass spice jar with plastic threaded lid

M6 or M4 metal threaded rod about 130mm

x2 nuts to fit the threaded rod

x2 washers

x1 domed nut to fit the threaded rod

Loose fitting springs to slide over the rod

ELECTRONICS

Amp

x1 10k potentionmeter with built in switch

x2 3.5mm mono screened audio chassis sockets

x1 PP3 9volt battery rechargable

Hiss suppression

x1 10k resistor

Lights

x3 red LEDs

Miscellaneous electronics

Some electronic wire

Some heat shrink wrap tubing or electrical tape

Old bike derailleur jockey wheel

Small piece of 20mm diameter black solid plastic rod

Small screw for fixing volume dial to potentiometer

Araldite two part glue

METAL ETCHING

Small piece of 1mm steel sheet approx. 50x100mm to be trimmed

Sticky backed vinyl for the stencil

Etching tool -

Old 12volt 1amp wall plug transformer [I had a 13.5v 1.5amp transformer to hand]

x1 long wire nail [mine 125mm long]

Piece of heat shrink wrap tube to fit or electrical tape

Thin piece of wire to attach cotton wool to nail

Tap water

Container to mix the salt water solution

GLASS STENCIL

Sticky backed vinyl for the stencil

TOOLS

General woodworking tools including -

Hole cutter/forstner bit

General electronic tools including -

Solder iron

Solder

Bread board [prototyping board]

Face mask for spraying

General basic metal cutting + drilling tools

Hot glue gun + glue sticks

Step 3: BASE

I decided to make the base with glued together pieces of Birch ply to add a striated interest to the base unit.

Alternatively a nice piece of wood or even a plastic box could work.

Cut the ply into strips slightly oversize to finish size, approximately 50x175mm

Cut enough to achieve a width of 55mm -

x7 pieces of 9mm thick ply or

x5 pieces of 12mm thick ply

or a combination of the two.

Add wood glue and stack the pieces together, clamp and leave to cure.

When cured, roughly square and size the block to the finished size required 55mm wide x 165mm long x 40mm high

Choose a good looking glass spice jar with a plastic lid that screws off.

Remove any spice from the jar, the label and the lid. If it has an additional flip cap, this can be discarded.

Find a hole cutter of the correct outer diameter of the plastic lid, mine was a hole saw cutter of around 40mm

Find the centre on the top of the ply block and drill squarely down to the depth of the plastic lid.

I then took out the bulk with a slightly narrower forstner bit.

Check the lids fit, should be a snug fit though will be glued in later.

Mark out position for the volume control wheel and the battery, I found this took a little of positioning and looking to see if they felt right.

Drill a hole for the stem of the volume potentionmeter, I used a router bit of the correct size though a standard drill will work as well.

To make the cut out slot for the batteryI made a MDF jig of the correct size with the addition of the router cutter guide.

Securely fix the jig in place and router out the slot. I decided I wanted the slot to cover the gold band at the top of the battery plus the thickness of the battery clip, in all about 15mm depth

Turning the ply block over carefully router out space for the wiresand potentionmeter to fit in.

Cut a little rebate around this cut out for a thin piece of ply to be cut in as a cover.

Drill a couple of 4mm holes from where the spice jar will fit into the bottom cutout for wires to go through...

...and another small hole from the battery slot to the bottom cut out.

Originally I wanted the 3.5mm audio sockets to go in the ends though I found I didn't have enough space...

...I relocated them within available space from the front besides the spice jar.

Drill the two holes, that match your audio connectors outer diameter,at a slight angle so they will sit square to the face after it is angled back...I made a simple ply angle guide to assist.

Cut and sand a slight angle to the block sides all around. I feel this slightly waisted look adds interest and allows the front lamination to show through.

Sand the edges and corners so it is pleasing to the eye and hands.

Step 4: Metal Etching

As the audio sockets were now located on the front, I decided to add a little metal plate with an etched graphic. The audio sockets would look as if they were the fixings for the plate.

Cut a stencil from some sticky backed vinyl sheet.

I am fortunate to have a Silhouette Cameo cutting machine that I can down load Illustrator files to, makes for super easy and accurate stencils. A careful hand and a sharp knife will do the job as well, though may take a little longer.

I also cut out the outside shape and the location of the audio jacks for ease of drilling in awhile.

I decided to use the graphics from the intro to the video that I made for the build PLAY IT LOUD which seems appropriate for an amp!

Stick the stencil to the 1mm thick steel sheet.

Now to make an etching machine -

Find an old working wall plug transformer, something around 12 volt 1amp is good. Mine was 13.5volt and 1.5amp and worked well.

Cut the transformer wire and connect crocodile clips to both the positive and negative ends. Mark the clips polarity.

Make the lengths of the wires different so less chance of the the clips touching and shorting if turned on and lying on the bench.

Get a long wire nail, i used a long 125mm long one.

Cut a piece of heat shrink tubing and slip over the nail leaving about 20mm clear at the head end and heat shrink.

Alternatively use some electrical tape.

Take a cotton wool pad and wrap over the nail head, attaching with some thin wire.

Now to etch

Make up some salt water solution, add a good amount of salt to a container and add water, I used hot water to help the salt to dissolve quicker, mix to a salty solution.

Attach the negative clip of the transformerto the nail...

...positive clip to the work piece.

Plug in the transformer.

Dip the cotton wall into the salt solution and apply to the stencil and hold down against the metal for a few seconds.

The metal will start to sizzle, it is etching.

Please do this in a well ventilated space as I am sure the fumes wont do you any good.

Etch all around the stencil and also etch the outer edge of the stencil to mark the shape to be cut out.

I went all over about three times to get a good deep etch.

The etched area will be black by the end.

Switch off the transformer.

Peel off the stencil and wipe the black off with a cloth...

...and admire your metal etching!

Mark the two holes with the end of a nail and drill for the audio connectors to poke through.

Cut the metal to the outer line shape that you have etched and file to a nice finish.

I wanted to enhance the etch so I sprayed black paint over the front and left to dry...

...then sand the front leaving the black within the etched graphics.

Cool!

Step 5: Electronics

I am a beginner in electronics and this is a really nice easy circuit to build.

I have to thank Deno Segovis of Hack A Week for this schematic and he has a great tutorial on exactly how to build it and how it works.

I added an additional little Hiss Suppression component, though unfortunately I can't remember who the source was for this, please let me know in the comments if you know and I will gladly credit them.

I wont give a full description of how to build this circuit as the Hack A Week tutorial tells you all you need to know, though some general points for this project -

I built the circuit on a bread board to check that all was working.

Tin all the component ends with solder, be careful with the LM386 chip as they don't like too much heat.

Solder all the components directly to each other, no circuit perf board is required.

Very carefully bend the tabs of the LM386 IC out flat so it can fit inside the glass jar and so that it looks intriguing within the glass jar.

When all of the circuit is soldered together you will need to make the scaffolding.

Hot glue the glass spice jar lid into the socket in the ply base block and unscrew the glass jar leaving the cap flush with the top of the ply block.

Cut a piece of threaded rod, I used M6 stainless steel threaded rod that I had left over from the Bike Shed Wardrobeto fit within the glass jar when in position.

Drill a hole through the bottom of the glass jar lid in the ply block for the threaded rod.

Screw on a domed nut to one end of the threaded rod...

...thread some springs up the threaded rod, a little loose as the circuit wires needs to be threaded through it.

Add a washer + nut to the other end and poke through the hole in the ply block and fix firmly with another nut and washer on the bottom side.

Attach the circuit to the scaffolding by threading the wires through the springs and twisting the wires to secure.

Poke the wires through the pre-drilled holes to poke out the bottom of the block.

Arrange the circuit components so they look interesting and make sure that no bare wires are touching to avoid any shorting.

Fix the battery to the battery clip, poke its wires through its slots hole and hot glue the clip to the bottom of the slot, push firmly into the slot and remove the battery when the glue has cured.

Wire up three red LEDs with their 470ohm resistors [9volt supply] and fit at the base of the threaded rod within the cap so that they will shine up the inside of the glass jar.

Twist connect all of the wires at the bottom of the base and as of the schematic solder them together, adding some heat shrink tubing to protect from shorting.

Check the polarity of the potentionmeter switch tabs and wire the battery to it. Fit the potentionmeter in place.

Screw the bottom ply cover in place.

If all has gone well the circuit should now work when the battery is fitted and the amp is turned on.

Step 6: Make a Vacuum Tube!

To make our 'vacuum tube' look as authentic as possible it needs some graphics on the back.

Real vacuum tubes will often have a logo, serial number and often place of manufacture stamped onto the glass...

...and ours needs one as well!

Make another vinyl stencil of your own design...

...check which is the back face and stick on the stencil.

Mask the rest of the glass jar with some masking tape and spray white.

Remove the stencil and you have a cool little finishing touch.

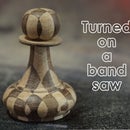

Step 7: Volume Dial

The volume dial of this amp was always going to be the jockey wheel from an old mountain bike derailleur as it would link the amp directly with the Bike Tyre Speaker that is its companion.

And it looks cool!

I needed to fill in the centre hole and I found a 20mm diameter black plastic rod in my workshop.

Drill a hole to match the potentiometer stem in the centre of the rod to the required depth.

Open up the jockey wheel centre hole with a coping saw and final finish with a file or a abrasive drum on a Dremel multi tool.

Glue the two together.

When cured sand off the rod flush with the jockey wheel on the top face.

Drill a small hole in the top centre for a small black coloured fixing screw that will screw into the top of the potentiometer stem.

Step 8: Put It All Together

So nearly finished...

...Carefully slide the glass spice jar over the electronics and screw onto the base...

...fit the jockey wheel volume control...

...fix the metal etched plate to the audio connectors with a little Araldite glue to hold firmly in place...

...push in the battery...

...plug in your MP3...

...and connect up your speaker...

...and PLAY IT LOUD!

If you like this project then I would really appreciate your vote in the Amps + Speakers Competition. Thanks.

This project is part of my YouTube series where I try to make cool and interesting projects.

Please check out my channel if you want to see more of the projects, if not there will be more coming to Instructables soon.

Why not check out what I am up to with pricklysauce.com

And also catch me on Facebook + Twitter

Just started on Instagram!

Runner Up in the

Circuits Contest 2016

First Prize in the

Amps and Speakers Contest 2016

Participated in the

Epilog Contest 8