Introduction: Making 3D Printed Circuit Boards With Tinkercad

Printed Circuit Boards, or PCBs, are an integral core in electronic devices. A PCB allows for electronic components like LEDs, resistors, and switches to be connected to one another permanently in order to make an electronic device. PCBs are comprised of two materials, conductors and insulators. The conductor acts as a path for electricity to flow between components. Insulators keeps electricity from flowing between paths and where we don't want it to go.

Creating a professional-grade PCB requires expensive tooling and are more commonly sourced from places like PCBWay.There are however many ways to make a DIY PCB such as CNC milling or acid etching, but these methods can also be costly, time consuming, and challenging for beginners.

Through this Instructable, I will be sharing an easy method to make DIY PCBs using Tinkercad, a 3D modeling program for all, a 3D printer, and some conductive filament!

Step 1: Prototyping Your Circuit

Before making a PCB, it's always a good idea to prototype your circuit using a breadboard and components. Tinkercad is of course well known for its 3D modeling capabilities but it also has a powerful circuit simulation features as well! You can use Tinkercad Circuits to put resistors, LEDs, batteries, and other components together as if they were on your workbench right in front of you. Check out more info about Tinkercad Circuits in my tutorials or one of my other instructables.

By prototyping your PCB, you can be sure your components will function as you intend them to and work out any bugs or wiring issues before putting time and material into manufacturing your printed circuit board.

Step 2: Planning Your PCB

Once you finish your prototype, it's time to plan out your PCB's layout. This is different than the breadboard prototype in the previous step as we will be planning out the tracks and pads that allow your components to fit together. Components are mounted to pads which are connected to one another using tracks.

This can be challenging to plan by hand with more complex circuits as you need to ensure all components connect from one to the next without crossing positive and negative tracks, as well as leave enough room for the components to be installed next to each other. If you're running out of room, you can make a multi-layer PCB that has sets of tracks separated by insulating (normal) filament. This gives you a lot more flexibility in space and layout, but also increases difficulty in planning.

There are plenty of programs that can help design your PCB like Autodesk EAGLE or Fritzing. While these programs are really intended to design PCBs for CNC milling or industry production, they are powerful tools that make mapping tracks and pads easier than planning by hand for complex designs.

In addition to planning where our tracks and pads need to be, it's also important to know the dimensions of your components. In the next step, we will be modeling our pads and if they aren't in the right spot, our components will not fit into the final board!

Step 3: Modeling Your Tracks and Pads

Now that we've planned out our PCB layout, it's time to model it! The first part we will be modeling are the pads and tracks our components will be connected to that will be printed using conductive filament. These parts can be drawn by grouping basic shapes like cylinders and boxes together. 3D printing PCBs really allows for limitless design possibilities, but here's a few standard dimensions I used to get you started:

- Pad Diameter - 4 mm

- Pad Through Hole - 1 mm

- Track Width - 2 mm

- Pad / Track Height - 2 mm

- PCB Thickness - 2 mm

There are ways to optimize the performance of your conductive filament in relation to pad width and height that we will be discussing in a later step. You'll also find that designing your PCB is very repetitive. Once one pad is modeled, duplicate it as many times as needed and use the ruler tool or work plane grid to space them out as planned in the previous step. Then use stretched boxes to create tracks between each pad.

You can also import SVG vector files that were drawn using vector design programs like Adobe Illustrator, Gravit Designer, or Inkscape. PCB design programs like EAGLE and Fritzing can also export files which can be converted to SVGs that you can import right into your Tinkercad design. Importing a vector file is not required to 3D print a PCB, but you may find vector design programs easier to work with for complex multi-layer designs.

Step 4: Finishing Your Model

After the tracks and pads are modeled, we need to design the rest of the circuit board that will act as an insulator between the conductive tracks. One of the coolest capabilities in this type of production method is that 3D printing allows you to design your board in any shape you'd like! Start by designing the general board around your tracks.

Once the outer board is drawn, we need to remove a cavity for the tracks / pads to sit into the insulator material. The easiest way to do this is to make a duplicate of our track/pad shapes and set them to be a hole. Align the hole shape onto the board and group the two shapes together. This should cut a cavity in the shape of your tracks / pads. Lastly, take the original track / pad model and overlay it with the cut out board. This hole does not need to go all the way through.

Cool Design Tip - The holes for your tracks do not need to pass all the way through your board. If you hole does pass all the way through, the conductive tracks will be exposed on both the top and bottom of your circuit board. If the hole does not pass all the way through, the bottom (or top depending on orientation) will be insulated. One method is not necessary better than the other, but they may serve different purposes.

Once completed, we need to export our model as individual shapes (one for the insulator material and one for the conductive material). Select one model at a time, the click Export. The "the selected shape" box should be checked at the top of this window. Choose your 3D file type, and export the model to your computer.

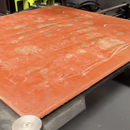

Step 5: 3D Printing Your PCB

As mentioned in previous steps, we will be using two different filaments to make our PCBs. For the insulator material, any normal PLA, PETg, or other choice of filament will do (I am using PolyLite PLA).

For the conductive material, we will need to use a conductive filament. There are a handful of conductive filaments out there but I've had the most success with Protopasta's Conductive PLA. This amazing filament prints with ease using the exact same settings as typical PLA filaments!

Do you need a dual head 3D printer to make 3D printed PCBs? No. You could design your model in such a way that allowed the insulator material and conductive material to reach different heights so filaments can be changed mid way though the print (assuming you used PLA with conductive PLA etc). You could also 3D print the insulator material and the conductive material separately, then assemble and glue them together post printing. However, these methods have their own set of challenges in comparison to dual head printing. If you do have access to a dual head 3D printer, you will be able to merge and assign each exported shape to the appropriate filament in your slicer software.

If your model calls for supports, I recommend you use the conductive PLA to create them in order to avoid insulating areas that should be conductive.

You should also keep your fill density for the conductive parts as high as possible to ensure as much surface area contact between layers to increase conductivity. We'll discuss this further this in the "Performance" step.

Step 6: Assembly

Once printed, it's time to add our components! As the through holes are only 1mm, it's highly probable that your holes will fill in during printing. To open them, you could us a pin (heat it to make it easier) or a small drill bit. I use a 1/32" upcut bit from my CNC Mill to drill out the holes with ease.

Once drilled, insert your components which should fit snugly into the board. To secure them in place, I like to use a soldering iron to heat and melt the conductive filament around the component legs. This will ruin the tip of your soldering iron so I recommend you use a tip dedicated to working with plastic! Alternatively, you could "cold solder"the components in place using a Conductive Ink Pen or Electrically Conductive Adhesive.

Once inserted, ensure all of the components are separated by insulating material. If additional insulation is needed, try using Liquid Electrical Tape.

Step 7: Performance

I'm sure you're now wondering how well these PCBs work....right? Overall, it works. But is it as good as a copper PCB? Or a breadboard and some wires? In short....no. To help explain why, let's compare the volume resistivity of some common materials. Volume Resistivity is the resistance to current loss or leakage through the body of material. Essentially, higher volume resistivity = lower conductivity(worse performance) so small numbers are good in this comparison.

- Copper, a highly conductive material, has a volume resistivity of 0.00000168 Ω⋅cm

- Aluminum Foil, a conductive household metal, has a volume resistivity of 2.65 Ω⋅cm

- Protopasta Conductive PLA has a volume resistivity of 30 Ω⋅cmperpendicular to layers

- Protopasta Conductive PLA has a volume resistivity of 115 Ω⋅cmthrough layers

So all in all, conductive PLA is conductive and works well for low voltage analog circuits. One important note is the difference in resistivity between perpendicular to layers in comparison to through layers. This means that current flows far more easily across a single 3D printed layer rather than through the vertical layers across a model. That means that you will see an increase in performance with tracks that are wider than they are tall. For more info on these stats, see Protopasta's detailed FAQ here.

From personal experience, my students and I have had lots of success with circuits using basic LEDs, DC motors, solar panels, or simple integrated circuits like 555 timers. We've had more sporadic performance when working with microcontrollers and PWM signals for things like servo motors and digital sensors.

Step 8: Endless Possibilities to Be Made!

As I'm sure you've now realized, conductive filament is pretty incredible stuff that unlocks a world of possibilities! With conductive filament, 3D printing technology, and software as easy to use as Tinkercad, really anything is possible when making aesthetically beautiful PCBs and unique creations. I hope you find this instructable informative and inspiring as you create awesome things!

Thank you for reading and happy making!

Runner Up in the

PCB Challenge