Introduction: Mechanical Clock - Swiss Lever Escapement

Have you ever wondered what goes on inside your watch?

Modern watches use a type of escapement called the Swiss lever. This method of timekeeping requires a extreme level of precision and craftsmanship, making it a challenge to anyone trying to make one for themselves.

This is my take at a more modern version of a mechanical clock. Opposed to using the traditional and much simpler pendulum, I opted for a type of escapement called the Swiss Lever. I've always wanted to build a fully mechanical clock for myself, and I am amazed at the more compact escapements, such as this one. Learning watchmaking made me realise the level of precision and detail required, so I decided to take a crack at it.

The whole assembly is created with Fusion 360, and each part is 3d printed.

How it works:

This clock behaves similarly to a pendulum clock, but where the pendulum should be, a oscillating mass which controls an anchor that is actuated by the wheel is in place. The Oscillating mass is powered by a hairspring, and the hairspring seems to never lose energy because the anchor, actuated by the wheel, is constantly putting kinetic energy back into the system.

- The anchor locked by the wheel in place, and is unlocked when the osciallating mass forcefully changes the direction of the anchor.

- In this moment, the wheel pushes against the anchor, which pushes against the mass, storing more energy into the system.

- This is called 'impulse' and is what allows the clock to keep ticking

- The torsion springs energy is staggard by a constant cycle of the locking and impulse phases.

Attachments

Supplies

Attachments

Step 1: Assembling the Mainframe

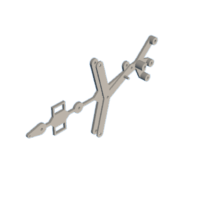

Using 3d printed parts from supplies, first assemble the torsion spring holder on top of the torsion spring, and assembling the mainframe, with the anchor and wheel in their respective places.

All moving parts can be fixed with the general 4.9mm or 4.8mm shaft. Preferabbly get a shaft that has a slightly resistive fit, then use sandpaper till it could rotate freely with minimal translational movement.

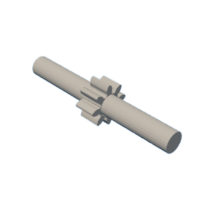

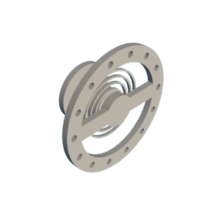

Step 2: Assembling the Escapement

In this step, you first put the jewel onto one of the 4.9 or 4.8mm shafts, fix a 2.9 mm shaft on the outermost hole, then attach the hairspring(the smallest spring) as shown in the picture.

After this is done you can put the module called 'weight' on top. Notice the numerous holes on the weight module. This can be used to put screws that can fit into a 4mm hole in place, and a nut at the end for extra weight.

Then, assemble the top half of the mainframe, using 4.9 or 4.8mm shafts to fix it in place as neccessary, and use 5mm spacers to raise the secondary platform above the first mainframe.

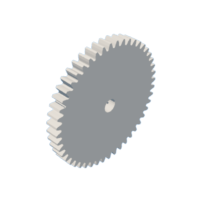

Step 3: Assembling the Gears + Second and Minute Hand

All gears can use the general 4.9mm shaft. Use spacers when neccesssary.

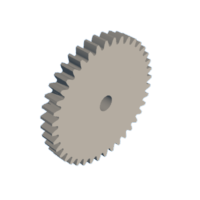

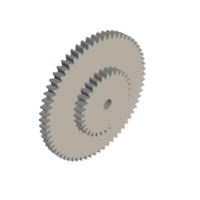

Start by assembling the 32 tooth on top of the central wheel, then attach as follows:

- 32 to 60-> 32 to 60-> 40(on the same shaft)-> 8 -> 48 to 8(48 is facing up, 8 is facing down) -> 80

- The numbers represent the amount of teeth each gear has

- The minute and second hand fit together, and is to be placed through the second 32 to 60 tooth gear

Step 4: Use It!

To use the clock, simply wind the torsion spring counter clockwise.

- it is easier to wind the spring back if you put the end you are turning at the edge of the table for easier grip on the mechanism.

- don't wind it up too much, as the rachet will skip, or the escapement will fail

Making this clock was a fun challenge and I hope you all learned something new after reading this instructable!