Introduction: Mold and Connector for Injection Molding

Injection molding is a manufacturing process of melting material and inserting it into a mold. This machine works by injecting plastic ore which is heated in the machine into the mold and then removing the plastic when the mold is cold.

The main goal of this project is to create a fitting for a mold that will be used to support educational activities for the Mechanical Engineering department of the HAN University of Applied Sciences, demonstrating injection molding during the 1st year of studies.

The specific output of the mold is a key chain that reads HAN, made of (thermoplastic) plastic.

Step 1: Defining the Problems and Set of Requirements

The main objective of this project is to help develop the tools to experience the phases and challenges of injection molding for educational purposes.

The HAN already has a manual injection mold as in the above cover picture.

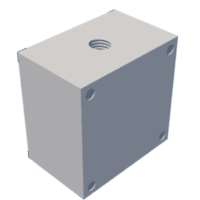

A prototype mold for the final product (from now on called "the key chain") is also available.

This project aims (outputs):

1) improving the existing mold (PDF file is provided in the attachment below).

2) creating (designing and producing) a connecting element for the mold and the injection molding.

3) advise about the thermoplastic type and PTEC (Production Techniques) to be used for the production of the key chain (testing of several materials samples will be used to access the quality of the made key chains and select the best one).

The mold, the connector, and the plastic material are the main products of this project. At the start, after knowing the function of these elements and setting the operational bordering conditions (i.e. injection pressure and melting temperature range of the available injection mold), a set of product requirements is needed to set what conditions must be met in the selection process.

Product Functions, points of attention: 1) The injection mold is manually operated 2) high temperatures can be reached which requires some users' safety. 3) The connector and the mold must be connected to each other and to the injection molding machine, see the schematic drawing above showing the relationship between injection mold, connector, and mold.

Bordering set conditions:

- mold geometry (see image)

- mold material: possibly keep current material (aluminum)

- pressure (injection) manual with maximum 955 KPa or approximately 9.5 bar of pressure (The force applied by an average human is considered from 300N to a lever. (See Step3 Design for the calculation).

- set range of temperatures (170-250 °C)

Fixed design requirements:

- easy to manufacture with available machines (connector)

- connector must fit with the existing thread of the injection mold 1-inch BSP Thread

- connector thread hard enough for dents not to occur.

Variable design parameter:

- low thermal expansion (connector) < 0.60 mm (measured on 250°C)

- good thermal conductivity k (connector) W/m K: as high as possible

- high thermal diffusivity α (connector) mm²/s: as high as possible (note: α = f(k))

- melting temperature as low as possible (key chain). Viscosity is also here considered.

- as cheap as possible (mold).

- high finished quality (key chain). Quality is defined when the key chain has a 1) continuous shape (no air gaps, doubles, incomplete parts) 2) the surface is not deflected or shrunk 3) Plastic doesn't show burnt marks. High key chain quality can be achieved by both improving the existing mold (e.g. placement of the injection point, adding air vents, clamping system) and when selecting the thermoplastic type for the key chain.

See also the attached table which summarizes the fixed and variable requirements.

Some considerations and possible suggestions will be made also about possible materials for the mold. Currently made of aluminum. For this thermal properties and price will be most considered.

The set of requirements will be used in the design phase to select the material, PTEC, and layout of the connector.

The plastic type and some PTEC characteristics are then further analyzed through testing of materials samples in different PTEC conditions. Finally, advice about the plastic type to be used is provided.

Last but not least, making a plan gives a clear vision of the time required and when certain tasks will be executed. This also helps to estimate when the project will be finished.

Attachments

Step 2: Planning

Project Planning

planning is made to ensure that the making of this project does not exceed the specified time limit. This project has a deadline before week 45th because it will be used by students as a learning tool for PTEC 2 (Production Technique). This planning was made on week 19th and has 13 working weeks to do the project until the deadline. To fulfill the free project criteria we must use 80 hours to finish the project. And here is the detail of the hours.

- Planning: 2 hours @block

- Research: 4 hours @block

- Manufacturing: 4 hours @block

- Testing: 4 hours @block

- Report: 3 hours @block

This project is taking a place at HAN. We do this project twice a week until the project is finished. During that 2 days, we mostly used it for doing research and manufacturing at different times. With this time planning, we achieved 80 working hours.

Step 3: Designing Phase

Research and calculation have been done in this design phase to ensure the products meet the right requirements. Moreover, 3D drawings are also made to visualize the result. Here are the explanations for the parts.

CONNECTOR - Material selection

Based on the set of requirements, the material for the connector must meet all the fixed requirements and selection can then be done based on the variable requirements. Below steel, stainless steel, aluminum, and brass which all meet the fixed requirements, are compared based on the variable requirements: 1) High thermal conductivity 2) High thermal diffusivity 3) Low thermal expansion.

- High Thermal Conductivity (W/m K)

Steel : 45

Stainless Steel : 15

Aluminum : 250

Brass : 110

- High Thermal Diffusivity (mm²/s)

This is the formula to calculate thermal diffusivity α = k/(ρCp)

α: Thermal diffusivity, k: thermal conductivity, ρ: Density, and Cp: specific heat. This is the result of the calculation.

Steel : 11.7

Stainless Steel : 4.2

Aluminum : 97

Brass : 36.5

- Low Thermal Expansion (cm)

This formula is used to calculate Thermal Expansion △L = L α△T. The PDF file below shows the missing variables for the formula.

△L: Change in length, L: Total initial length (10 cm), α: Thermal coefficient expansion, △T: Change in temperature (250-30=220 C).

Steel : 0.033

Stainless Steel : 0.04

Aluminum : 0.055

Brass : 0.047

Based on the data above, brass is the most suitable material for the connector. It fulfills the fixed requirements and it has better thermal properties (part of the variable req.) compared with stainless steel and steel. Due to its higher hardness (Rockwell B-Scale), brass can withstand the pressure (on the thread), that is applied during the injecting process, better than aluminum which considers a softer metal. The hardness of brass is between 22-133 (average 77.5 RBS) compared to aluminum (29-96, average 62,5 RBS). Aluminum has then the tendency for dents to occur. Therefore, aluminum does not meet the specified criteria because of the softness of the material compared to brass.

CHOICE => Brass is then the selected material.

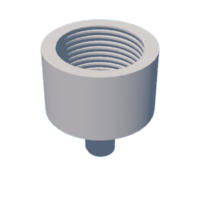

CONNECTOR - Drawings elaboration

There are then 3 fixed design requirements that must be met, namely 1) the connector can be fitted with 1 Inch BSP male thread to the injection molding machine barrel. 2) The connector can be clamped by a 40mmØ heating element. 3) The connector can be connected to the mold.

The prototype design has a length of 45mm with the widest diameter of 40mmØ and the smallest at 10.15mmØ (see the picture above). In addition, on the connection point to the mold (10.15mmØ), there is also an inlet hole that has a size of 4mmØ for passing melted thermoplastic to the mold.

MOLD - Pieces of Advice for improvement

The mold is a prototype that HAN already developed. The prototype consists of two blocks of the mold with the letter HAN inside them. To make this a working piece, an additional design and improvement need to be added. 1) The mold must have an intake hole for molten thermoplastic. 2) The mold must have the connecting point (thread) to be able to connect to the connector. The thread and the intake hole must be in the center of the mold to produce a symmetrical result. This is to prevent air stuck at the edges of the mold. 3) Adding an air vent is necessary to get rid of the air while injecting the liquified thermoplastic. One air vent is placed on the bottom of the mold and two vents are placed on the bottom edge of the mold. 4) Changing the angle of the letter is needed to prevent the air bubble stuck on it. Some of the ways are to make the letter more angled or V-shaped to prevent air bubbles and also to help the ejecting process. The picture of the mold can be seen above

Besides aluminum, copper can also be a suitable material for making this mold. Copper has a higher thermal conductivity than aluminum and also it is classified as a soft metal. However, because this is still in the prototype stage, there will be a lot of tests and errors, and a lot of materials is used, therefore, the price (3x more expensive) is also one of the considerations. The material properties can be seen in the PDF below.

APPENDIX - Injection Pressure Calculation (used in Step1 to estimate one of the bordering set conditions).

A certain pressure difference will appear in the connection point between the mold and the connector. It will affect the applied pressure and reduce the pressure on the connector and the mold. Here are the calculations for the pressure difference.

Calculating the torque created by the lever to the gear

τ = r ⋅ F1

τ = 0.5 ⋅ 300

τ= 150

τ = torque (N⋅m), r = lever length (circular lever)(m), F1 = force created by the lever (normal human force) (N)

Calculating the force created by the gear to the piston

F2 = τ / r

F2 = 150 / 0.05

F2 = 3000

τ = torque (N⋅m), r = radius of the gear (m), F2 = force created by the gear (N)

Calculating the pressure created by the lever

P = F2 / A

P = 3000 / π ⋅ 0.01^2

P = 954929.65 Pascal or 9.55 Bar

P = Pressure, F2 = Force created by the gear (kg⋅m/s^2), A = Piston area (m^2)

The pressure so calculated is then used in the below calculation.

Calculating the melting viscosity

Q (mm^3/s)= A ⋅ v

𝛾 (s^-1)= 32 ⋅ Q / π ⋅ D^3

(Pa)= P ⋅ D / 4 ⋅ L

η ( Pa⋅s) =/ 𝛾

Q = 314.15 ⋅ 50 = 15707.96

𝛾 = 32 ⋅ 15707.96 / π ⋅ 4^3 = 2499.99

= 954929.65 ⋅ 4 / 4 ⋅ 23 = 41518.6

= 954929.65 ⋅ 4 / 4 ⋅ 23 = 41518.6

η = 41518.68 / 2499.99 = 16.63

Q= volume flow rate (mm^3/s) , A= piston area (mm^2), v= piston rate (mm/s), 𝛾= Shear rate (s^-1) ,  =shear stress (Pa) , D= inside diameter (inlet) (mm), P= pressure applied by lever, as calculated in the previous point (Pa) , L= capillary length (mm), η= melt viscosity (Pa ⋅ s)

=shear stress (Pa) , D= inside diameter (inlet) (mm), P= pressure applied by lever, as calculated in the previous point (Pa) , L= capillary length (mm), η= melt viscosity (Pa ⋅ s)

Calculating the pressure drop in the connector

ΔP1 = (6η / tin) ⋅ (R2 / d)^2 ⋅ ln(R2 / R1) (R1 and R2 can be found in the picture above)

ΔP1 = (6 ⋅ 16.63 / 2 ) ⋅ (30 / 4)^2 ⋅ ln(30 / 4)

ΔP1 = 5654.45

ΔP1 = Pressure difference on the connector (Pa), η = melting viscosity (Pa ⋅ s), tin = injection time (s), R2 = radius of the barrel i.e. piston radius (mm), d = thickness of the molten plastic (mm), R1= inlet gate (mm)

Calculating the pressure drop in the mold (rectangular cavity)

ΔP2 = 12 ⋅ L ⋅ η ⋅ Q / W⋅ h^3

ΔP2 = 12 ⋅ 50 ⋅ 16.63 ⋅ 15707 / 40 ⋅ 10^3

ΔP = 3918.11

ΔP2 = Pressure difference on the mold (Pa), L = product length (mm), η = melting viscosity (Pa s), Q = volume flow rate (mm^3/s), W = product width 9 (mm), h = product height (mm)

CONCLUSION: From the calculation above shows that there is a pressure difference between the applied pressure and the connector + the mold. The total pressure between the connector and the mold is around 9572.56 pascal [ ΔP2 (3918.11) + ΔP2 (5654.45)] and results in a reduction in applied pressure from 954929.65 Pascal or 9.55 Bar to 945357.09 pascals or 9.45 Bar ( [ P (954929.65) - ΔP (9572.56) ].

Step 4: Supplies for Manufacturing

Material list:

- Aluminum plate 60x60x32 (mm)

- Brass rod Ø42mm, 47,45mm L

Tools used:

- Lathe: This machine is used to form a brass rod from a cylindrical shape into a shape designed as a connector. This machine also plays an important role in making thread and opening holes because it keeps the product in a symmetrical position.

- Pressed drill: This machine is used to punch holes in the mold that will be used for opening and threading. This machine is used because it can make straight and precise holes compared to hand drills.

- CNC machine: This machine is used to make shapes from molds. This machine is often used in the engineering world to make molds because of its very high accuracy and precision. Therefore, this machine is used because the mold design has a complicated shape and requires high detail to avoid product defects.

Step 5: Manufacturing Phase: Connector

Based on the previous material selection, brass is used to manufacture the connector. Brass is available at HAN in rods with a size of 47.45mm in length and Ø42mm in diameter. This is used to manufacture the connector accordingly to the design drawings.

For forming the main shape of the connector, a lathe machine is used for the whole making process. Here are the steps that have been taken:

- Use a turning tool attached to the lathe machine to reduce the workpiece length from 47.45mm to 45mm.

- Use a turning tool to reduce the diameter from Ø42mm to Ø40mm (the whole rod)

- Use a turning tool to reduce one side of the workpiece diameter from Ø40mm to Ø10.15mm over a 10 mm length (creating so the mold connection).

- Use a turning tool to produce a ramp transition between two different diameters.

- Drill a hole with an M10 drill bit at the larger end of the workpiece (Ø40mm side) to make the boring process easier (this process is for making a 1-inch BSP female thread).

- Use a boring tool to reduce the inner diameter until it reaches Ø30mm inner diameter for 22mm in depth.

- Use one inch BSP tap to make the female thread in the opening hole (Ø30mm diameter hole of the above step).

- Use an M10 die on the other end of the workpiece (Ø10.15mm diameter) to make a male thread for the connection to the mold. (Using straight cutting oil is recommended to make the result smoother and less effort on tapping)

- Drill a 4mm intake hole in the center of the Connector.

In this case, a 4mm intake hole is drilled because is the perfect size of the intake hole. If the intake hole is small, is hard for the material to get into the mold and it will cool down quickly, if the hole is too wide, the material will not get equal heating which means some of the material will melt (near the brass) and the material that in the middle of the intake hole is still cold. This must be prevented to avoid the faster cooling of the material.

In addition, the reason why both steps are made in the Lathe machine is wanting to make the result of the workpiece symmetric and accurate, unlike taking out and using a table vice.

There is a defect in this product due to incorrect use of the machine during processing. however, this defect does not affect the use of the product. This defect is found on the outside of the product which is shaped around the product and has a depth of about 1 mm.

Step 6: Manufacturing Phase: Mold

The mold is a prototype that is already available at HAN. The mold needs to be developed and improved to make it as a working piece. The molds have a size of 60x60x32 (in millimeters). Several steps need to be done before the mold can be placed and used for the demonstration with the injection molding machine (and the above-manufactured connector). Here are the several steps that need to be taken :

- Use 4 pairs of screws and bolts (M5) to tighten the mold (and drill a hole between the two mold's plates, so the result will be symmetrical - see next step).

- Drill the main intake hole with the size of a 4mm drill bit for a 10mm depth.

- Drill 7mm down to the main intake hole with the 8.5mm drill bit for the thread (8.5mm is selected for an M10 tap, based on the above 'tap chart - metric coarse tapping drill size').

- Tap the hole with an M10 tap to make the female thread. (Using straight cutting oil is recommended to make the result smoother and less effort on tapping)

- Make air vents at the bottom of the mold with a small-sized file.

One of the molds has 3 air vents to make the process easier. It's placed at the bottom of every edge of the mold. An extra air hole is being placed because the previous test shows an air bubble on the edge; this is some action to prevent that from happening.

Step 7: Thermoplastics Materials Properties

Material selection is an important phase in this project. If the material is not suitable, it will affect the quality of the final molded product. Therefore, only suitable materials for injection molding are used for this project.

Three materials have been tried in this step, namely: HPDE (High-Density Polyethylene), PS (Polystyrene), and PP (Polypropylene). The results of the tested samples have been later used to access the level of finishing quality as defined in the variable requirements.

Information about the tested thermoplastics:

Melting point:

HDPE: 126°C - 135°C (later tested at 200°C due to a mistake)

PS: 210°C - 249°C (tested at 235 °C)

PP: 160°C - 163°C (tested at 170 °C)

The data above it shows that PS has a higher melting point than the other the others. It means that working with polystyrene needs more time due to heating the whole setup. This would also result in higher energy consumption but based on the result comparison, this material gives the best finishing quality compared with others.

Volume and mass:

The volume of the mold is approximately 20000-28000 mm3. This is calculated by making an approximation, assuming the shape of the key chain to be a parallelepiped with dimensions l length 50mm, b width 10-14mm (without and with the thickness of the letters), h height 40mm ( hence the volume is l x b x h). 22500 mm3 is used for the mass calculation below.

HDPE: ρ 960 [kg/m³] ==> mass 21.6 gr

PS: ρ 1060 [kg/m³] ==> mass 23.85 gr

PP: ρ 900 [kg/m³] ==> mass 20.25 gr

Step 8: Product Testing

Using Polypropylene, High-Density Polyethylene, and Polystyrene several prototypes of the keychain have been made and the resulting samples have been compared (see the PDF on step 9). The process of producing the key chain takes a place on the injection molding machine with the limits that have been determined from the research and calculations that have been done. The result from research and calculations will be used for manufacturing the key chain. Here is the step-by-step for manufacturing the key chain by using the set limits.

PROCEDURE:

The injection mold machine is turned on and heated up, then the granulated plastic is added, and left to melt for a certain period of time. Afterward, the plastic is pressed into the mold. The step-by-step procedure is explained below.

NOTE: The display on the machine is showing the current power that the machine use. The power used is directly proportional to the temperature. The temperatures have been obtained experimentally (this information is gained by measuring the temperature with a temperature gun after a certain power was set). Based on excel the following trend line is obtained to calculate the temperature y in the function of the read power x:y = 0.7852x - 81.1 ( can be found in PDF file below)

315 = 170°C

350 = 190°C

385 = 215°C

390 = 225°C

400 = 235°C

410 = 245°C

STEP-BY-STEP Injection Molding Process:

Preparation 1:

- Preheat the barrel at 20°C above the average melting temperature, i.e. to 255/220/190°C PS/HDPE/PP respectively for 10 minutes.

- Continue by lowering the temperature to235/200/170°C for another 10 minutes for PS/HDPE/PP respectively (The temperature needs to be higher because the nozzle of the mold is small). An infrared temperature meter cannot measure the temperature of the mold. however, point the temperature meter to the barrel or connector to see the current temperature.

These processes need to be measured by an infrared temperature meter.

Preparation 2:

- Calculate the amount of plastic that going to fit in the mold and add 20% for the external access. (approximately 23.86/21.6/20.25gram PS/HDPE/PP respectively).

- The granule should be put into the barrel while waiting 5 minutes to melt

Injecting step:

- Press down the injection mold lever until the lever cannon move further. After removing the mold from the machine, press the lever again to release the rest of the plastic in the barrel.

Final step:

- Remove the mold for the machine using a heat-resistant glove and wash it with water to make the cooling process faster.

- Clean up all the access plastic that is still in the machine.

Step 9: Result

The samples showed several differences from one another. Many parameters can influence the final result, for example, low temperature, small airhole, loose mold, slow injection, and cold mold. In the ATTACHED FILE the tested samples are compared in relation to the problems encountered.

CONCLUSION:

From the pictures above, we can notice that one of the recurring problems is gaps in the continuity of the letters. This could be solved by changing the shape of the latter of the mold. The current letters HAN on the mold have 90-degree sharp edges; this could result in air being stuck at the edges. A 'V' shape on the edges (i.e. angle<90-degree) could help solve this problem.

Compared with manufacturers that use high-pressure injection molding, manual Injection molding has approximately ±100 kg of pressure compared with the bigger machine that can deliver up to 5 tons. Some of the observed defects could be solved by using higher-pressure injection molding machines such as deformation in shape due to fast shrinkage that is related to the cooling time.

Based on the tested material samples HDPE showed the best finishing quality (as defined in the variable requirements).

Due to the key chain having a thick main body, therefore, base on the results, HPDE and PS is can give a high finished quality compared with PP.

Attachments

Step 10: REFERENCES

https://www.aqua-calc.com/calculate/volume-to-weight

https://www.cavitymold.com/injection-molding-of-polystyrene/

https://designerdata.nl/materials/plastics/thermo-plastics/polystyrene

https://www.polymerdatabase.com/Commercial%20Polymers/HDPE.html

https://polymerdatabase.com/Commercial%20Polymers/PP.html

https://goodcalculators.com/thermal-expansion-calculator/

https://www.toray.eu/eu/plastics/torelina/technical/tec_017.html