Introduction: Wooden LEGO Duck

I have been obsessed with LEGO ever since I can remember. Those small plastic building blocks were definitely one of my favorite toys as a kid and I still buy LEGO sets from time to time, even though I am in my thirties now (I have also written three Instructables that have to do with LEGO so far).

As a new mother my son is definitely still too young for the small LEGO pieces, but he has a bunch of LEGO PRIMOS.

I have known for a few years that the LEGO company has also produced wooden toys and wanted to buy one. Sadly they are rare and most of the time really expensive. The wooden LEGO duck is by far my favorite toy of that line, but I was never able to buy it. So I finally decided to make my own. The bonus of making one myself is that I can give it to my son and not worry about its value.

The special thing about it is that when it moves it opens and closes its beak. I hope that you will have as much fun with it as I do.

Step 1: A Brief LEGO History

Many probably don't know, but before the founder of LEGO Ole Kirk Kristiansen produced the small plastic bricks, he solely produced wooden toys.

In 1934 he came up with the name "LEGO", which stems from the Danish words "LEg GOdt", meaning "playing well". Ole Kirk always said that "children deserve the best" and later adopted the motto "only the best is good enough".

After solely producing wooden toys until 1948, Ole Kirk purchased a plastic injection molding machine that would change LEGO forever and make it the household name it is today. From that moment on, he began replacing the wooden toys with plastic ones.

It took until 1958 until a patent was filed for what became the modern LEGO brick. They were a vast improvement over LEGO’s earlier Automatic Binding Bricks.

The wooden lego duck was first produced in 1935 and was fabricated up until LEGO stopped making wooden toys in 1960. It is without a doubt the most famous wooden toy LEGO ever produced.

If you would like to see more wooden LEGO toys than go ahead and check out this photostream.

Step 2: Replicating the Original

There are many different versions of the lego duck, so I had to decide, which one I would like to replicate. I decided to go with the most famous version, but use a wire as the hinge for the head and not a wooden pole (this version was also produced). Later Ole Kirk switched over to making the entire mechanism out of wire. You can of course build and paint the duck however you would like.

Before starting I had to figure out the mechanism. I wanted to take a closer look at the original duck in the LEGO house, but sadly couldn't due to COVID-19. So I started looking around the web and found this technical drawing. While it shows a newer version of the duck (with a wire mechanism and not a wooden one) it was really helpful, but as you can see in the picture all the measurements were removed. After some more research, I found this full building guide of a copy of the LEGO duck made from plastic bricks. Luckily on page 4 for there is a small snipped of the drawing with measurements, so I was able to scale everything to the correct size.

So my duck should be extremely close to the original one.

As for the wood I decided to go with larch since I bought a vintage toy (a broken one I am planning on fixing) and I am very sure that it is made from larch.

Step 3: What You Need

Here is what you need to make your own wooden LEGO duck:

Material

- Wood (4 mm, 8 mm, and 18 mm thick). As explained in the last step I used larch. Sadly I can't plane 4 mm thin. Therefore I used plywood for these parts.

- 6 mm round wooden pole (two 63 mm long pieces and one about 108 mm long)

- 1 mm wire (I tried thicker wire, but couldn't bend it) and thinner wire is too flimsy

- Paint: red, green, blue, black, white, brown, dark yellow*

- Varnish*

- Spray Adhesive Glue

- Carbon Copy Paper (I used this one (#CommissionsEarned**))

- Nails (three 1.5 mm x 20 mm)

- Optional: primer

Tools

- Scroll saw

- Drill press (1.5 mm; 2 mm; 3 mm; 6 mm; 7 mm; 10 mm drill bits)

- Disc sander

- Pliers

- Scissors

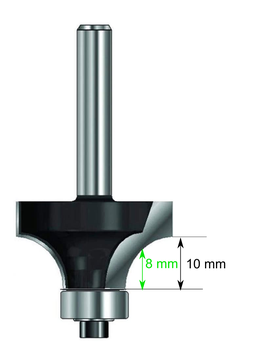

- Router (rounding cutter: diameter 32.7 mm, radius 10 mm with a bearing)

- Paintbrushes

- Clamps

- Optional: 44 m hole saw

* Please make sure that all the paints and varnishes are safe to use for toys. In Europe, they have to comply with DIN EN 71/3 "Safety of toys - Part 3: Migration of certain elements". Check the can, it should have a label on it.

** As an Amazon Associate I earn from qualifying purchases.

Step 4: Let's Get Started

Start by downloading the templates from the last step and print them. Apply spray adhesive to the back and stick them to the wood that matches the thickness that is noted on the paper.

Please make sure to align the grain along the length of the duck. The template also includes the wheels, should you not want to use a hole saw. To cut the other 8 mm pieces a circular saw may be better than a scroll saw. But I recently got my scroll saw and wanted to practice straight lines.

Step 5: Sawing

Now on to cutting the pieces. I used a scroll saw to so. There are black lines, blue lines, and green lines.

The blue lines are needed so that you can hold the pieces during the routing and should help you with getting better corners.

So in the first go, cut along the lines that are thicker in the first image of this step. You should cut precisely around the black lines and somehow close along the blue lines as shown in the second picture.

As you can see in the picture I didn't cut too close to the line on the 4 mm pieces since I had some tear out and figured that I could easily sand them to the correct size, as shown in the third picture.

Step 6: Routing

Now onto the routing. I got the bit I needed but had to find out that it didn't fit into my router. So I had to remove the base plate. I wanted to round the corners, but just slightly and not all the way. So instead of using the whole radius of 10 mm I used about 8 mm, as shown in the image on the left.

In the end, the pieces should look like as shown in the last picture. Make sure to round both sides.

Step 7: Sawing #2

Now back to the scroll saw. Simply cut along all the black lines. As you can see in the third picture, I forgot the inside of the front of the duck and had to remove it later.

Step 8: Drilling

Onto the drilling. Most of it is pretty straightforward. The sizes of the holes are noted on the template. I used a hole saw to cut the wheels, as you can see in the second picture.

The green lines on the front piece of the duck marks a 7 mm hole that needs to be drilled. Mark the center of the hole on top of the duck and drill all the way through. Make sure that the piece is standing perfectly upright otherwise the mechanism won't work.

Step 9: Assembly

Before the assembly, all the pieces need to be sanded. But make sure not to remove the paper from the bottom pieces as shown in the first picture, since you will need them for alignment later on.

Simply glue the wings to the body pieces as shown in the second picture.

Then glue the eyes to the top of the head of the duck as shown in the third picture. I used a piece of wire for the alignment.

As you can see in the last picture I marked where the moving part goes and sanded some of it away so that the head can move smoothly.

Step 10: Assembling the Bottom

Now cut the wooden pole to the correct length. The axles need to be 63 mm long and the wooden pole that moves the head about 108 mm.

The wheels and the duck aren't centered. Therefore you have to make sure that the arrows are pointing to the front and the thinner part underneath the holes has to be on the bottom as shown in the second and third picture.

Step 11: Adding the Duck to the Bottom

In order to attach the duck to the bottom, I used a vice. I tried using a clamp on my prototypes. but it didn't work too well.

Place the duck in the center and use your 108 mm pole to align it. The pole has to go through the 10 mm hole in the bottom and 7 mm hole that goes through the front of the duck. To glue the pieces together, I used weights as shown in the third picture.

Once the glue is dried I used nails to add some more stability as shown in the last picture.

Step 12: Painting

Onto the painting. The plywood I used had a defect, so before painting, I filled it with wood filler.

The original LEGO wood toy I own is not primed, but I decided to prime mine so that the paint stays on it better.

There are many different versions of the duck out there so you can, of course, paint it however you would like.

I have uploaded my color scheme to this step, which is a direct copy of the original one. Feel free to use it. There are two files, one for each side. I used carbon copy paper to trace the lines onto the duck, as shown in the third picture.

I painted one color at a time, but if you have paint that has better opacity than mine you might want to think about using base colors and adding the details ontop (it took me about five layers for each color).

I found a fun little story about varnishing the toys:

Godtfred Kirk (Ole Kirk's son) is laying the finishing touches on a consignment of wooden LEGO ducks. This means applying coats of varnish, and finally bringing the boxes with the finished toy ducks to the train station for dispatch. Back at the workshop, Godtfred proudly announces to his father that he has done something really clever and saved the company money. – “How did you manage that?” asks Ole Kirk. – “I gave the ducks just two coats of varnish, not three as we usually do,” is Godtfred Kirk’s answer. Back comes his father’s prompt response: – “You will immediately fetch those ducks back, give them the last coat of varnish, pack them and return them to the station! And you will do it on your own – even if it takes you all night!”

So, of course, we are going to add three coats of varnish.

Attachments

Step 13: The Mechnism

Next, we are going to attach the mechanism to the axle. I marked the middle of the axle and place the small distance piece onto it. I was afraid that it could break if I would directly drive the nail into it and therefore predrilled a 1.5 mm hole. To sink in the nail head I drill another short 4 mm hole into it.

Place the piece into your toy and drive a nail into it. Afterward, I covered the hole with some glue and sanded it smooth.

Step 14: Attaching the Wheels

Now attach the wheels and paint the visible parts of the axles red.

At this point, we are going to dry-fit the mechanism. Place the wooden pole through the top of the neck and place the head onto it. Depending on how well you cut and aligned the pieces the length may be slightly off. Turn the front wheel and check whether the length of the poles is right. If so, use a 1 mm wire and attach the head to the body as shown in the last picture. Otherwise, shorten it slightly and test again.

Congratulation, you are done. I hope you have fun with it!