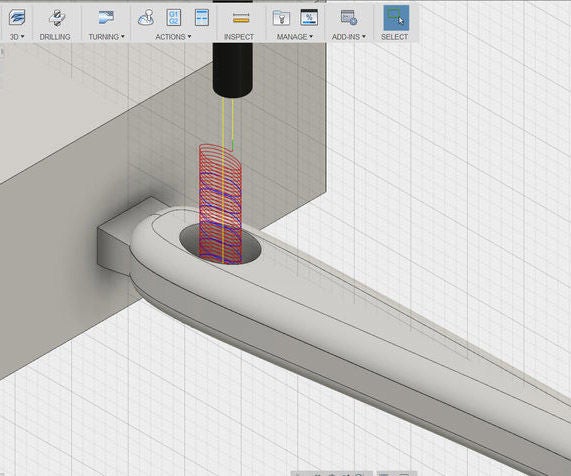

Welcome to 3D CAM! In this class, you will learn Computer Aided Manufacturing (CAM) skills for 3D surfacing using Fusion 360. Fusion 360 is software that can be used both for design (CAD) and manufacturing. After following step-by-step instructions to create 3D toolpaths for a wooden serving spoon, you will learn how to machine it on a CNC router.

This class requires no previous experience with 3D toolpathing. However, you should have an understanding of CNC fundamentals and 2D CAM. Check out ou…

Show moreWelcome to 3D CAM! In this class, you will learn Computer Aided Manufacturing (CAM) skills for 3D surfacing using Fusion 360. Fusion 360 is software that can be used both for design (CAD) and manufacturing. After following step-by-step instructions to create 3D toolpaths for a wooden serving spoon, you will learn how to machine it on a CNC router.

This class requires no previous experience with 3D toolpathing. However, you should have an understanding of CNC fundamentals and 2D CAM. Check out our CNC class and 2D CAD and CAM class to learn more. Although in this class we will be programming toolpaths specifically for a DMS router, what you will learn about machining strategy and 3D CAM will still apply to other CNC routers.