Introduction: How to Waterproof Your Electronics or PCBs

In this instructable we’re going to discuss methods for protecting a circuit from the environment and this applies in general to printed circuit boards but you can take these tips and tricks and use them in other applications as well.

This will mostly not be the scientific and engineering way of doing things, but more a practical and affordable approach, using chemicals that can be bought easily and used at home. I will show you a few different methods, tell you their advantages and disadvantages as well as places where you can purchase the supplies needed.

Step 1: Watch the Video!

The video describes all the methods shown here so I recommend watching the video first to get an overview of each method, the advantages & disadvantages that I find through various tests of the proposed solutions.

Step 2: Source the Required Chemicals

These are chemicals that I usually keep in my electronics lab so I don't have to wait for them to be delivered when a certain project needs it:

- Nail polish, get this from the dollar store.

- PCB Varnish Spray: TME, Amazon. This particular type and model is available in the EU but if you are in a different region you might want to search for what is available locally.

- UV Curable Soldermask: Aliexpress, Ebay, Amazon.

- Zoomable LED UV Flashlight: Aliexpress, Ebay.

- Kafuter 705 Transparent Silicone Adhesive: Aliexpress, Ebay.

Do not use your wife's nail polish, do not go through her stash. You've been warned! Get the cheap stuff from the dollar store.

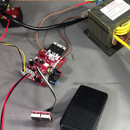

Step 3: The Different Methods

Method #1 - Clear Nail Varnish

This is probably the easiest and most common method hobbyists use to try and prevent moisture and dust from getting on a circuit board. It has the advantage of being very cheap, easy to find and easy to use but it also has some disadvantages that we’re going to discuss.Nail varnish will set pretty fast and become this rather hard coating on your circuit board.

So you probably want to have your circuit well tested before coating it with nail varnish, there is no going back. Also nail varnish since it’s designed for nails doesn’t like the high temperatures so if your circuit is getting hot, the coating might get scorched and just peel away.Even with these disadvantages nail varnish has its place and will be used occasionally.

Method #2 - Special PCB Varnish

It’s likely you will find this type of product with a similar name from a different manufacturer, this is for the European market, I believe it’s made in Poland and it’s relatively easy to find it in Europe. If you are in the US you might have different brands selling a similar solution. This is basically a coating in the form of a spray, so it’s easy to apply it evenly across the entire circuit board. Once it hardens, it remains transparent and creates a hard protection layer but still maintains some flexibility that prevents it from cracking if you have some flexing in your pcb. On the can it also says that you can solder through it, i haven’t tried that, but I would imagine it just melts at the point of solder. So this lacquer is a bit more optimized towards our application, this is probably my go to solution when I need to protect a pcb from moisture for example, I highly recommend you get yourself a can of this stuff

Method #3 - UV Curable Soldermask

This makes a lot of sense because well soldermask has been used from the beginning of pcb manufacturing to protect the copper. It has great temperature stability, great adhesion really ideal for protecting some exposed copper or a small modification done to a board. You can get uv curable solder mask in a variety of colors, you can find this stuff on aliexpress, it comes in a syringe form and it’s very inexpensive. Then you will need an UV flashlight, put a drop of this, shine the UV light and in 30 seconds the stuff will harden to a nice protection layer.

But this also has some limitations, for example it’s pretty liquid stuff, so you can only do a thin protection layer with this stuff and it works best on flat surfaces. You can’t for example coat an entire assembled pcb in this stuff, it’s just not practical and you will not get good results. It works best for flat stuff like exposed copper on a pcb or small mods and repair wires.

Method #4 - Clear Silicone Adhesive

My next solution involves this recently discovered silicone adhesive, it’s made by this company with a name that’s rather difficult to pronounce but it’s model number 705. This is Transparent silicone adhesive, specifically for electronics. They claim it’s non conductive, it has good adhesion and good temperature stability. So this is something new to me, I haven’t tested it over longer periods of time to see if it’s good long-term but so far I like what I’m seeing.It’s rather soft you can pierce this with a multimeter probe and do some measurements and I believe it will still maintain a decent amount of protection even after it’s being pierced judging by the density of the material. This has the advantage that you can also use it to secure various elements to a pcb, to stop them from flapping in the breeze.

Step 4: Final Thoughts

There are certainly other methods you can use to protect your electronics from the environment, for example I could also mention conformal coating or potting compounds but those are not exactly hobby grade methods because the chemicals involved usually come in large quantities which are difficult to ship because of their MSDS and also difficult to handle in a typical home environment.

There is a blog post on the subject if you would like to send me some feedback you can do so in the comments and you can also checkout my Youtube channel for more awesome projects: Voltlog Youtube Channel.