Introduction: Make a Simple Spirit Level Jig for Knife Grinding (ala Bubble Jig). I Made It at Techshop

So when grinding the edge on a knife, one of the hard bits is keeping the angle you are holding the blad at consisteant as you go back and forth on both sides, especially when grinding the curved part.

This is especially true of flat grinding.

If you don't want to make it, or want to see how to use it, just go here, this guy invented the idea,

http://bubblejig.com/

Basically it's a magnet a bubble level and a 1 dimensional gimbal to allow you to adjust the angle.

Push a knife whos grind you wan to copy, say a Mora, to the sander, click the jig on to the blade,adjust till the buble is in the center of the level... you can now copy that angle exactly while grinding.

The Bubble jig guy sells wedges too, that are at the common knife grinding angles.

Also you can just use a adjustable protractor or angle finder.

but lets go through the steps on how to make your own for a couple bucks.

You need

1" or 1.5" aluminum angle 3" in length or more.

1 1/4in wing nut

2 1/4 in lock washers (see pics for the kind i used)

1 14in by 1.25in pan head machine screw

1 .75-1" diameter rare earth magnet

1 cheap bubble level, i could only find the ones with 2 levels(like this), so i just cut it apart.

Epoxy.

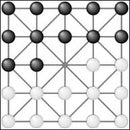

You can see a completed bubble jig in the bottom let corner of this pic, I'll try to get a better one up later.

I made it at Techshop!

Step 1: Mark and Cut 2 X 1" Pieces of Angle

Mark and cut 2 x 1" pieces of angle

Step 2: File the Edges Clean, and Center Punch One Side

File the edges clean, and center punch one side just above the center of each piece of angle

Step 3: Mark a Curve on One Side of One of the Pieces of Angle

Mark a curve on one side of one of the pieces of angle

Step 4: Drill the Center Punched Holes, Grind Away the Corners to Make the Curve on the 2nd Angle

Drill the center punched holes, grind away the corners to make the curve on the 2nd angle

Step 5: Apply Epoxy

Apply the epoxy,

the curved piece gets the bubble level epoxied on,

the non curved piece get the magnet

Epoxy the bolt on the inside of the curved pice to make adjusting easier

Step 6: Assemble

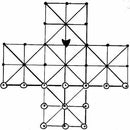

After the epoxy is set, assemble as per the pics

Your spirit level jig is now ready to use!

Set the angle and grind away

I made it at Techshop!