Introduction: Running the Mill

LOAD PROGRAM

Follow these steps to transfer your program to the machine.

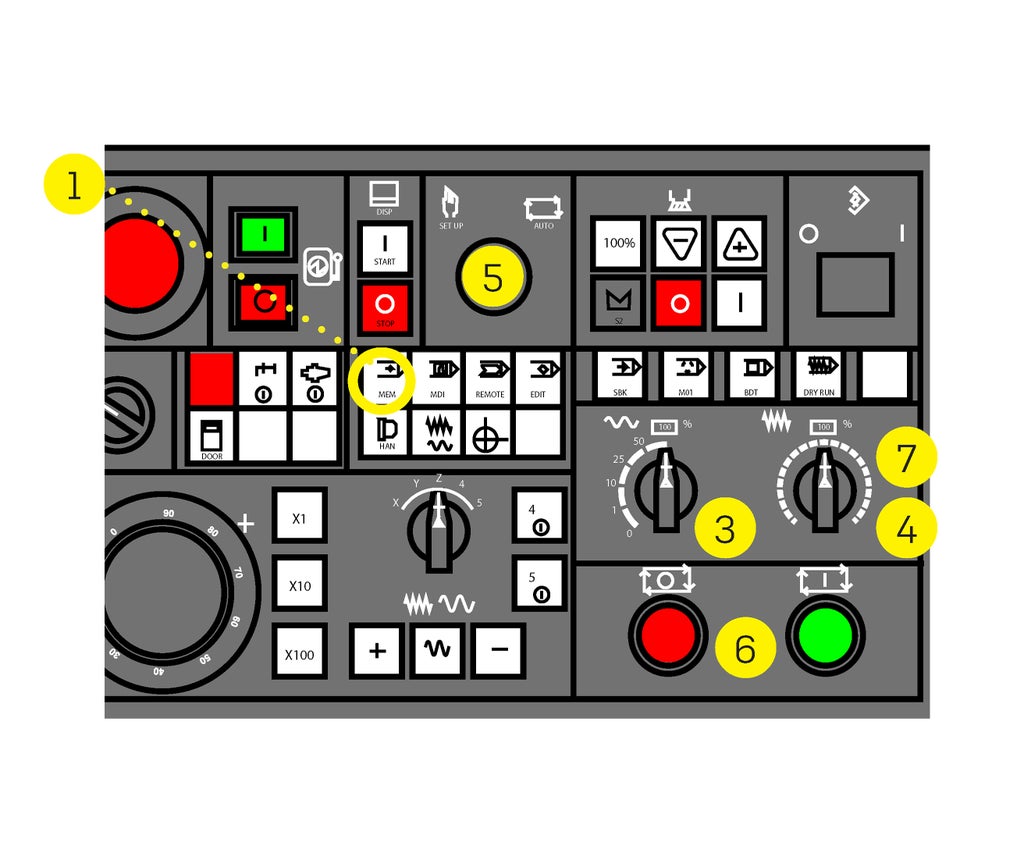

- Press MEM.

- MEM mode is used to run programs.

- Insert USB into controller on left side of screen.

- On the display, under Running, select Program Mgr.

- On left side of screen, select Data_SV.

- Select Input.

- Highlight your program.

- Select OK.

- Green text “Executing” will appear while program is transferring.

- Program will transfer to Data Server.

- This can take a while. For larger programs, use Filezilla File Transfer Protocol software.

PRE-RUN CHECKLIST

You're ready to run the program. Double check that these tasks have been completed.

- Stock is measured and updated in CAM software.

- There are no errors in CAMplete.

- All tools are loaded in machine.

- Tool length offsets have been measured.

- The Work Coordinate System (G54) is correct.

- Stock is centered in the vise.

- Correct torque was used to attached vise to platter.

- Correct torque was used to tighten vise jaws.

Using coolant

Because of the spindle's high speed and feed rate, coolant is required.

- Flood coolant will automatically be turned on after every tool change.

- To disable flood coolant for a dry run, use dry run mode (red button).

- Toggle flood coolant on and off to increase visibility while tool is descending in Z.

- Use through spindle coolant for deep pockets and holes.

Step 1: Run Program

RUN PROGRAM

- Press MEM.

- Highlight program in Data Server.

- Data Server is under Running/Program Manager.

- Select OPEN

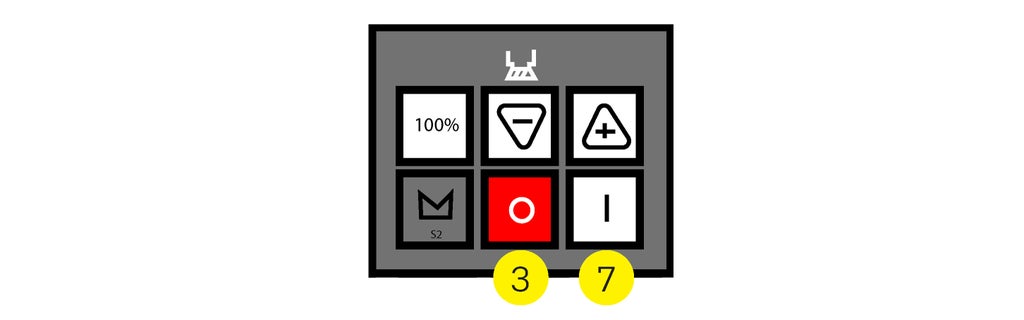

- Turn Rapid Rate to 10%.

- Turn Feed Rate to 0%.

- When Feed Rate is 0%, neither the spindle nor the trunnion will move, even for rapid moves.

- Switch key to AUTO.

- Press CYCLE START.

While program is running

- While looking through the wiper viewport, keep one hand on Feed Hold and the other on Feed Rate.

- Use Single Block (SBK) after each tool change.

- Turn off before tool begins cutting.

- Turn off coolant when needed to verify tool length offset.

- Change Rapid Rate to 1% and Watch Distance to Go in Z on the main screen to verify tool length offset.

- Use FEED HOLD or Feed Rate at 0% to pause the machine.

- Press Feed Hold and Rewind to reset to the beginning of the program.

Inspecting part during program

- If you need to inspect your part mid-program, you must turn off the spindle before opening the door.

- Press FEED HOLD.

- Press HAN.

- Turn spindle off.

- Turn coolant off.

- Press Door Unlock.

- Open door, check part, and close door. 7. Turn spindle on.

- Press MEM.

- Turn coolant on.

- Press CYCLE START.

Don't remove the part yet

As long as you keep your part inside the vise, you will be able to continue machining at any point.

- When you’re finished, inspect the part and check tolerances.

- If another user needs the machine and you have more operations to complete, remove the vise and keep it at your desk.

- When returning to the machine, ensure the G54 Work Coordinate System coordinates are the same as before.

Step 2: Clean Up

Plan on 30 Minutes to clean the mill.

CLEAN UP

Run the Goodnight Program.

- On the Display, under Running, select Program Mgr.

- Select Path 2 and highlight Goodnight Pier 9.

- Select Open.

- Press CYCLE START.

Clear chips.

- Wipe chips from machining platter, vise, and trunnion with a red rag.

- Do not use compressed air.

- Walk around to the back of the machine and empty chip bins into the Haas Mill chip container.

- Do not put chips into metal recycling.

Final Steps.

- Remove USB from controller.

- Press E-stop.

- Switch key to SETUP.

- Press Power Off.

- Wait for computer to shut down completely.

- Turn the MAIN POWER switch to OFF.

- OFF is green.

- Make sure oor and surfaces are clear of objects, tools, and chips.