Introduction: Trendy Belts From Old Bicycle Tires

In my opinion developing this project is a must for any good ecologist as you. Indeed cycling around the city would further contribute to preserve environment if we find an alternative use of consumed or punctured tires.

This is not an original idea, recently you can buy these belts in fairs and markets, and six years ago opendesignclub wrote how to make tread belts (you also could read his instructable).

I used some thinner bicycle tires for my project, the one you use on your technical racing bicycle, or on your stylish fixed gear one. Usually these tires are also coloured and they could have stripes along all the tread, so you can obtain very trendy belts. Don't worry if the tread is not in good conditions, that's exactly the purpose of this project, and only if you're so lucky to cut your tire right away with a glass you will have a brand new belt. In this instructable I describe how I made four different belts from one very consumed coloured tire, two pierced black ones almost new, and a wrecked mountain bike tire.

Step 1: Materials

Base material is obviously an used bicycle tire, but you also need a belt buckle and, depending of the type of buckle, probably a pair of rivets or Chicago screws. The rivets are cheaper, and they work great for this project, the only disadvantage is that you can't unscrew them as with Chicago screws. But Chicago screws also have the risk to loosen.

In the picture you see that the tread with blue stripes also has an hole, and I tried to hide it with the belt loop. So if you have a damaged area you have tho options: cut it away, since you don't need the full length of the tire, or hide it under one or two loops.

You can find many different types of belt buckles on eBay, and some of them are very funny, but I chose to use some classic ones.

Step 2: Measure and Cut

After cutting the tread with some margin more than the exact length (see step 6), I washed it with soap and a brush. At the beginning it will leave some black tincture which derives from the brake pads consumption. But once washed it will not probably leave any trace on your pants.

Now you can cut the edges so to obtain the exact width of the buckle. As you see you have to narrow the last 7-10 cm of strip, alternatively you can cut all the entire tread wider as the bar length.

Step 3: The Prong Slot

Mark the spot where to cut a slot for the lock, then make two holes at its extremities, and with a cutter remove the rubber between the holes, so to obtain a slot. This slot should be about half inch long.

Step 4: Punch Out Rivets Holes

Now place the buckle and mark the spots where to punch two holes for the rivets/chicago screws. The screw close to the buckle should keep the prong in place, so punch the hole pretty close to the bar.

Then cut a stripe from the piece of tread you split up, the length has to be the exact measure so that it can wrap the belt with no overlapping.

Step 5: Belt Loop

Connect the stripe's edges with the stapler so to make the loop. As you will see for next belts, you can give to the loop the flat shape with a simple solution, just iron it or place it in the toaster kept in shape with a metal peg. I didn't do that for this my first belt.

Then insert the buckle, close the first rivet, insert the loop and add the last rivet.

Step 6: Adjustment Holes

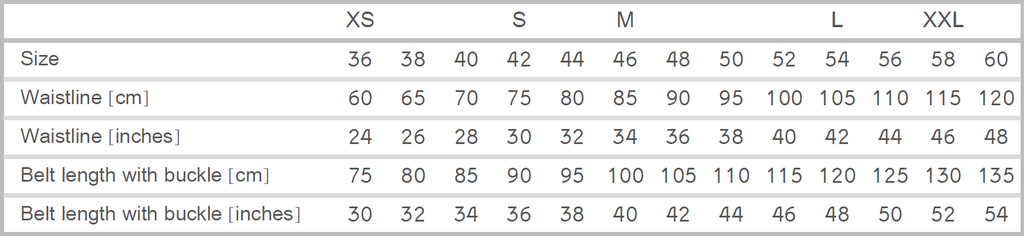

Now cut the exact length of the belt and mark the adjustment holes position, you can leave about one inch between them, or a bit less. To know the exact length measure your waistline and add about 15-18 cm (with the buckle length). If the belt is not for you, take note that a small waistline is about 60 cm (24") for a girl and 75 cm (30") for a guy, and that belly can grow up to 120 cm (48").

Look the following table to determine the right length, then punch out the center hole at the waistline distance from the end of the buckle, and add two or more holes at each side of the first one.

Step 7: Last Finishing

if you want o make a different loop, or an additional one, you can cut a different portion of tread, so to have a text engraved or a single coloured stripe instead of two.

My first trendy belt is ready to wear, let's see what we can obtain with a bit different tire and expedients.

Step 8: Another Belt

These two black tires are in a better shape, since they both are punctures but not too much consumed.

I decided to cut the first belt to fit the smaller buckle I have, which is a standard 3.5 cm one, and I didn't leave the tread centered, instead I cut it leaving the writing well in view, so that the carved tread occupy half width.

Step 9: Frame Connections

Also in this case I punched out two holes to make the slot, then I added the holes for the rivets.

Step 10: Loops

As you see you can make different loop styles, on the left is a stripe with an engraved writing, and on the right the full carved tread occupy the loop.

The I fastened them with the stapler as before, but this time I decided to try to heat them up, to see if heat will make them keeping the shape. That works very good, you can either ironing them, or close them in a metal peg and put all in the toaster for 5 minutes.

Step 11: Punch Holes

As before measure the right length, cut a nice shape at the extremity, and punch out holes.

Step 12: Ready

This belt is completed too. it's smaller than the first one, and its black tint makes it more stylish, anyway I like the brand writing on its side.

Step 13: This Is Centered

This third belt is very similar to the last one, since the tire was identical. But I used the 4 cm buckle and I centered the belt in the tread width, leaving the writing visible as on the other belt.

You know by now the full process. Here I punched the slot and inserted the belt in the buckle. Then I punched out the holes for screws. Now measure the exact length and make the size holes as described before.

Step 14: Another One Completed

For this belt I inserted both loops in the turn-up, which is a bit larger than the other belts.

As you see these black tires are very appropriate for not very garish belts, but you can obtain gorgeous results with almost every type of treads.

Step 15: Last the Wrecked One

Indeed I also tried to reuse a very old and consumed tire, I washed and brushed it, I cut out the tread, I measured the right length.

Step 16: Let's Promote This New Ecologist Trend

Then I punched the holes, refined the ends and connected the buckle. As you see it's worthwhile, maybe not so trendy, but undoubtedly sturdy!

So, what are you waiting? Go looking for a nice buckle and an used tire ;-)

Step 17: [UPDATE] New Creations

Give a look also to another belt I made from a white tire and a huge belt made from an old Superga tire.