Introduction: 3D Printed Artificial Muscles: Erector Set

After experimenting for many years with artificial muscles that are 3D printed, I have come up with a fairly efficient configuration of muscles and bones that can be printed in modular form. This allows for the muscles and supporting bone structures to be reconfigured in various ways to create many kinds of robots.

This creates a kind of erector set that is plug and play--to make robots that are limited only by your own creativity.

Step 1: How It Works

The most efficient pneumatic artificial muscle I have developed so far, I call the Omega muscle. Shaped like the omega sign, it is at once a muscle, a tendon, and a ligament that locks into a slot in a bone structure. It provides maximum expansion or rotational movement while occupying a small volume at rest.

Like most robotics, it involves a delightful oversimplification of the complex mechanisms used in animal movements.

Step 2: Tools and Materials

3D Printer- Access to a 3d printer that can print flexible filament like Ninjaflex and regular PLA

Fusion 360- This cool program allows you to design and create any physical object that you can imagine in 3D form. The only limitation is your imagination.

If you want to scale up, modify, or create new muscle or bone modules, this program or a similar one is required. Student and non-commercial versions are available for free. You can find info here: https://knowledge.autodesk.com/support/fusion-360

Ninjaflex filament-Available on Amazon

PLA filament

Loctite fabric glue- Available from Walmart or Amazon. I tried several dozen glues, paints and sealers, and the Loctite glue was the only one that would fuse well to the Ninjaflex and remain flexible. It also glues well to vinyl tubing and acrylic materials.

1/8"vinyl tubing and fittings-available from: http://www.usplastic.com

MEK solvent-Available at hardware stores.

4-40 bolts-1/4"-Available on Amazon

Step 3: Printing the Modules

Print The Muscles

I used an old Replicator 2 printer to print the Ninjaflex muscles. Here are the settings used in MakerBot:

No supports

Infill: 100 per cent

Shells: 2Layer

Height: .2mm

Temp: 225 C

Speed Extruding: 30 mm/s

Speed Traveling: 150 mm/s

Seal The Muscles

After the muscles are printed, 1/8" tubing is inserted in the muscle hole. To seal it from leaking air under pressure, the muscle is then dipped in a mix of Loctite glue and MEK solvent. It usually takes two coats. More details can be found here in step5: https://www.instructables.com/Soft-Robots-3D-Prin...

Print The Bones

You can use your favorite settings for your 3D printer to print the PLA bones. The files are designed to print without supports.

Assemble The Robot

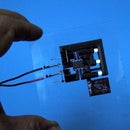

The muscles slide into the bones and are held in place by washers and 4-40 bolts that go into preexisting holes in the bones. The holes are sized to act as a tapped hole for the bolts.

Attachments

Step 4: Controlling the Muscles

In a previous instructable I have detailed how to create an air pressure controller that can control these kind of muscles. It can be found here: https://www.instructables.com/Air-Muscles-Make-an-Artificial-Muscle-Robot-Contr/

You can also 3D print your own control valves and control them with your favorite microcontroller. Details here: https://www.instructables.com/3d-Printing-Servo-Controlled-and-Other-Valves/

Step 5: Pull Muscles

The omega muscle can also be used as a pull muscle using fishing line as a tendon. The two lines can be used to rotate an elbow or a wheel. Actuated together, they can pull twice as much.

Attachments

Step 6: Other Possibilities

Shape Shifting

The omega muscle can produce more than 90 degrees of rotation which could be used to create robots that fold and unfold.

Snake Robot

I have been working on a snake robot. Creating scales that attach to the bottom and slide forward but not back is proving to be a challenge.

Improving The Modules

The modules are experimental and have much room for improvement. They tend to be somewhat wibbly wobbly from side to side. Balancing the pressure of opposing muscles is fairly tricky. The addition of external ligaments or improved bones could stabilize the structures. I have included a Fusion 360 file of the solid muscle which can be modified and then hollowed to create various size muscles.

The bones and muscles can be scaled up to create stronger muscles or scaled down to create quite small muscles to activate a switch or act as an pressure indicator.

First Prize in the

Robots Contest