Introduction: 3D Printing of "The Wave"

Presenting my 3D printed sculpture, Ive been referring to it as "The Wave" In this Instructable I will be taking you through the process of how I made this lovely little piece. This work is an original design that I've put quite a bit of effort into. So I figured I might as well share it with the community. Enjoy!

Side note: This design is a product of an Autodesk educational suite of Autocad 2015

Step 1: Printing of the Parts

The first step is to download the provided .stl files (see next step) and print out the parts

The part list consists of the following:

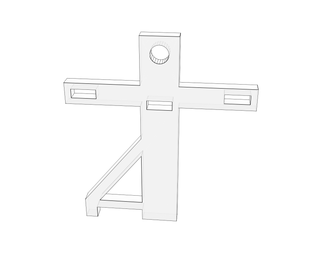

x1 Arm hinge support

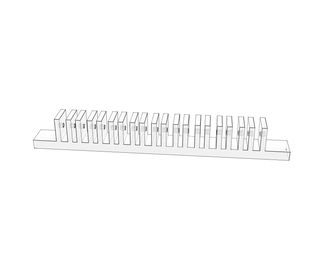

x1 Camshaft support

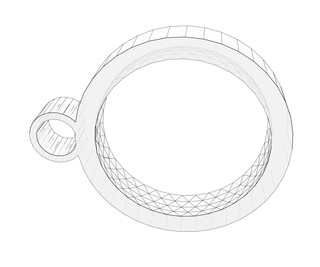

x1 String guide

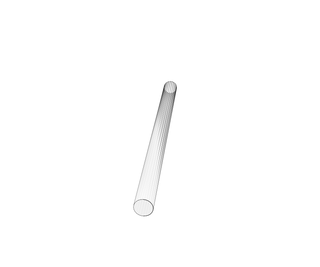

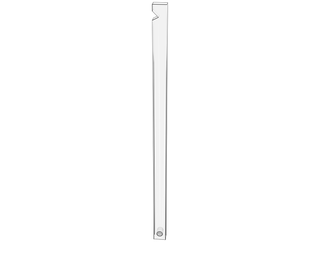

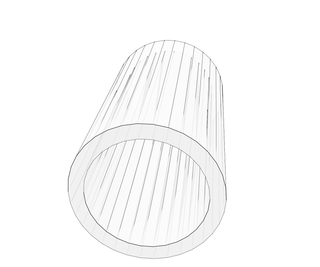

x1 Main shaft

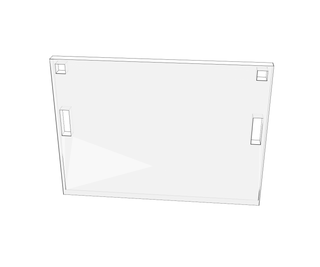

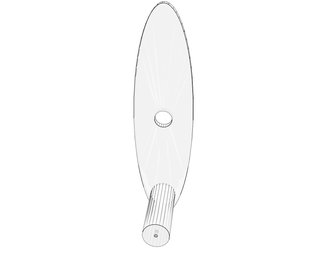

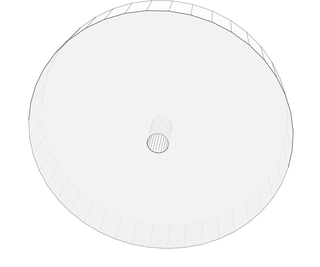

x1 Base plate

x1 Crank handle

x1 Crank handle sleeve

X1 Crank handle sleeve retainer

x2 Vertical supports

X10 Arms

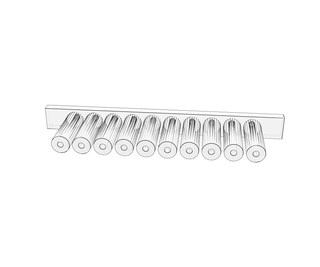

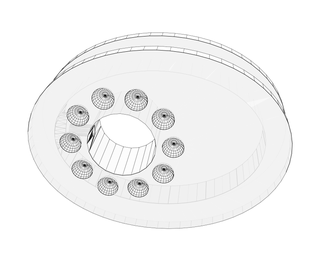

X10 Camshaft offsets

X10 Ball bearing sleeves

Step 2: Files to Download

Attachments

Step 3: Tools and Other Materials

You will need:

A means of 3D printing

A hobby knife

A sharpie

Medium viscosity CA glue

One small screw about 1cm in length m2ish diameter, with a pointed tip

Medium sand paper

Thread (pictured and in the build video, i say to use fishing line; witch works. Although sewing thread is far easier to manipulate)

x10- .5'' Diameter Ball bearings (look on amazon)

Step 4: Basic Slic3r Settings

Two of the pictures show the infill settings, layer and perimeter settings. All the parts print in 15% infill density with 3 top/bottom layers along with 3 perimeters. The one exception is the base plate, with can be printed from 5%-10% infill density.

The third picture shows the support material tab, and the settings utilized. Support material need only be applied for the camshaft offsets. All other parts are set to print flat without support.

ABS was the plastic used for this project.

Some post print sanding and reaming may be required, depending upon the quality of your prints.

Step 5: The Build

When all is said and done with printing, its time for assembly.

Keep in mind, this is the first instructional video I've ever made

I tried my best to include all the info, but some things were over looked. The assembly of the crank handle and the protrusion of the main rotating shaft were not covered in the video. To assembly the crank, slide the crank handle sleeve over the cylinder on the main crank handle, and screw in place the retaining top. Once thats done, the handle can be CA glued onto the main shaft. The main shaft should favor about a quarter inch to one side of the vertical supports, this is where the handle will be glued.

A lot of time and effort went into this project. It's been a blast from start to finish, and i hope it brings you as much entertainment as it has brought me.

Thanks for viewing!

Step 6:

More to come 0.o get ready for the big build