Introduction: Aluminum Foundry

This is my take on making an aluminium foundry furnace from an old propane tank. It's not like this has never been done before (like here), but it never hurts to see another person's take on the same project.

Before I started this project, I read many builds of the same and took their precautions to heart.

As stated by many others:

USE YOUR BRAIN. THIS IS A POTENTIALLY DANGEROUS ACTIVITY. YOU TAKE ANY AND ALL RISKS IN DUPLICATING THIS. BLAH... BLAH... BLAH...

I like what this person wrote:

A few Safety words:

Coming into contact with fire and boiling melted metal can be very dangerous so always work safe using proper full body protection including respirator mask against toxic fumes and dust from mixing refractory materials. Never melt in a wet area or near water, if water comes into contact with the boiling aluminium it might "blow" in your direction.

The info in this instructable is based on my experience.

I disclaim any responsibility for any resulting damage, injury, or expense.

All use by you of this website is at your own risk, work safe.

Step 1: Getting Any Combustbiles From the Tank

The propane tank I have was very old. The valve was a simple needle valve, so all I had to do was open the valve and let the excess gas out. As the gas was expanding, it froze (thermodynamics), so I just needed to wait.

Then I drilled a 9/32 hole in the top. I kept the drill flooded with oil to prevent any heat build up and the corresponding explosion.

After that I hooked up a 1/4" urethane tubing to my garden hose and filled the tank with water to force out any remaining gas. Then I emptied the tank.

Step 2: Cutting the Tank

I scribed a line 11-1/2" from the bottom as a guide for the cut.

Then it was onto a 4" angle grinder to cut the tank along the line. The cut went faster than I anticipated. It only took about 15 minutes to lop the top off.

With the tank in two, I used the angle grinder to clean up the cut edge.

Step 3: Lid Center Hole

I used a can of carburetor cleaner to mark a circle on the lid. Then after clamping the lid down, I drilled a bunch of holes along the marked circle. Then I used the angle grinder to grind the rest out.

I have a box of fence staples, so I welded them to the inside of the lid to create support for the refractory cement when I get to that stage. The staples were galvanized, so I was in a well ventilated area to keep from inhaling the toxic fumes.

Step 4: Burner Pipe

The burner pipe needs welded into the tank. The fire exiting out of the burner should be more or less tangent to the cavity between the crucible and refractory walls. So after purchasing a 9" plant pot, I placed the crucible and pot into the tank visually centering all three.

So as seen in the photograph, the burner needs to be placed 3-1/2" from the centerline of the tank.

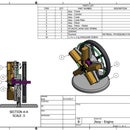

My welding skills aren't exactly stellar, so the closer I can cut the hole in the tank to match the 1" pipe, the better. Cutting a close fitting hole in the tank is not a simple matter. So I went to a mechanical CAD package to which I have access and modeled up the tank shell in the sheetmetal package. I cut a ø1.315" hole in the model and flattened the CAD model to create a template (which is the .pdf in this step).

For verification, I went to Grabcad and downloaded a 3D model of a propane tank the modeled in the 1" pipe. (Note that 1" pipe doesn't have a 1" dimension anywhere on it. A 1" pipe is actually 1.315 OD).

I printed the template and applied it to the tank. I used a Sharpie to mark the egg-shaped hole. Then I used a Dremel tool to cut out the hole.

After dry fitting the pipe, I made the marks and milled an angle on the pipe for a better fit in the tank.

This was followed up by welding the pipe into the tank and more fence staples to act as reinforcement for the refractory.

Attachments

Step 5: Preperation for the Refractory Pour

I used a 9 inch planting pot as a form for the refractory cement. To line up the pipe with the planting pot, I made a cut (via trial and repeated fittings) in the pot. After using duct tape to fill the holes and gaps, the tank is ready for the castable refractory cement pour.

Using a largish Solo cup, I created a similar form for the tank lid.

Step 6: The Refractory Pour

I read somewhere that adding perlite to the refractory cement will improve its insulation capabilities, so I purchased a bag.

Following the directions on the 25lb pail of castable refractory cement (which isn't same same as refractory motar), I added water, 1/4 bag perlite, and mixed it thoroughly. It was far too solid to be pourable.

Then things went very very wrong. Either I screwed up and can recover or I screwed up royally.

I added water to the point that the mortar/perlite mixture was pourable then poured the material into the tank. It was evident that I didn't have enough material to fill the void. So I pulled the form (planter) and poured the refractory back into the contractor bucket.

I added the rest of the perlite as filler and added water. Then I made to too soupy.

I replaced the planter and poured anyway. The form is a bit crooked. If the concrete sets at all, I'll have to pour in some filler material to level out the bottom and the top.

Step 7: The Damage... ...The Recovery

You're just reading the next step. For me it's two weeks later.

I let the form dry for a week then pulled the pot. The results were actually less bad than I was expecting. After chipping away the loose concrete, there was a significant pocket around the fire tube. It was still an issue, but at least I was able to recover.

I did so by purchasing more refractory and (1/4 bag) perlite and mixed them to a consistency of a soft clay. I could then use my hands (covered in latex gloves) to hand fill the hole and clean up the walls.

I used the remainder to fill the lid.

Step 8: The Burner

Now that I have a cured refractory, it was time to work on the burner.

Many people that have done this say to drill as small a hole as possible for the propane gas to flow through. This is good advice, but I went the route of the "King of Random". I used a MIG welder wire tip as by orifice. The one I used is 0.028". This way, if the hole is too big or small, I can disassemble the burner and replace tips to to get different orifice sizes. I used a calipers and metric thread gauge to determine the welding tip was indeed threaded M6-1.0.

So I obtained the following:

- 0.028 welding tips (M6-1.0 thread)

- 1-1/2" x 1" pipe coupling

- 1/4" x 5" lg NPT pipe nipple

- 1/4" NPT cap

- a 1/4" ball valve I had laying around for gas throttling and shut off.

First I placed the nipple about how I wanted it on the coupling and made a mark about where I wanted the welding tip. Then it was off to drill a 5mm hole through one wall so I could tap the hole with an M6 tap. I drilled hole was as perpendicular and centered as possible.

Then (after squaring and finding the center) I drilled through the coupling. The pipe nipple had an OD of .549". I didn't have a drill bit close enough, so I drilled through a pilot hole then a 9/16" drill bit.

After deburring the parts, I assembled the components on the furnace using teflon tape on the pipe threads. Then I tack welded the nipple to the coupling ensuring the orifice is as centered and axial aligned as I could.

Step 9: First Firing

The first issue I had on the first firing of the furnace was that the fire would repeatably enter the 1" pipe. That is not a good thing. After experimenting with my hand as an air damper, I decided I need to make a damper for the air inlet.

Using some scrap I have laying around the garage, I welded up a small door which covers the air inlet. I can open it as required with a 3/8" bolt which holds the door partially open.

With the damper installed, I re-lit the furnace. I slowly brought up the temperature a couple hundred degrees at a time. As I increased the temperature, excess water in the mortar would steam off. So when I saw "steam" coming off the furnace, I held the temperature. When the steam stopped, I raised the temperature.

My infrared meter maxes out at 1200 degrees, so I was able to at least get that hot.

Step 10: Crucible Tools - Pouring Rod

On to making the crucible tools. It's not like I'm grabbing something 1500 deg F with my bare hands.

So I started with the simplest tool. I need a ring attached to a rod which I can pick up the crucible and manipulate it for pouring. I purchased some low carbon 1/8" thick x 1" wide steel strips from the local hardware store.

To create the ring, I cut the strip length to the circumference of the crucible. Then clamping the strip in the vise, I progressively bent the strip into a "ring". After a couple of trial fits, I welded in a gap filler then a hollow steel tube to the ring.

Step 11: Crucible Tools - the Grabber

I needed a tool to grab the crucible out of the furnace. I've seen many videos that people pull their crucible out their furnace with a pliers. That is extremely unsafe.

I cut some strips and bent them into "half-rings" in a similar fashion as the pouring ring. After welding a steel strip to each half-ring, I bent the strip 90 degrees in the vise with an old pipe wrench.

After some measuring and drilling some strips, I made a grabber that clamps around the crucible naturally. The idea was that the weight of the crucible would cause the grabber to clamp harder. It kind of works, but I still need to clamp on the handle with my hands.

It's not quite as good as I envisioned, but it far far better than a set of Channel Lock pliers.

Step 12: Crucible Tools - Dross Scoop

The last tool is a tool to scoop out the dross (crap that isn't aluminum which floats to the stop of the melt). I found a rusty piece of angle iron on the garage floor. I cut it to about 3" long and milled some flats in it. After welding the angle to a 3/8" steel rod, I had a scoop.

Other people have used stainless steel mixing spoons. That probably works just fine as well.

Step 13: Crucible Conditioning

The instructions on the crucible box recommends coating the interior of the crucible with Borax prior to actually using it.

So I purchased some Borax from the the supermarket and poured some into the crucible and fired up the furnace. This was really the first time I really got the furnace hot.

After about 20 minutes of firing I had a mass of somewhat molten Borax. I used a 3/8" steel rod to grab a mass of Borax (imagine red hot cotton candy) and rub the mass on the interior walls of the crucbile. A bit later all the Borax was melted to a liquid.

I then removed the crucible and picked it up with the Pouring Rod and carefully "swished" the molten Borax on the inside of the crucible. Then I poured the extra Borax out onto the ground (not concrete).

A note on safety. During this operation I was wearing a full face shield, large & heavy gloves, and a welding jacket. I need to be "safe" to some extent....

Step 14: First Melt

I purchased a cast aluminum candy dish and some golf clubs from a flea market for my first melt.

I broke up the candy dish with a hammer and melted it first. Then when I had a puddle of molten aluminum, I dipped each club into the puddle until it melted. I then retracted the handle.

Some handles were carbon fiber and they don't like that 1500 deg F environment and caught on fire.

Although I had my wife film my first pour. Unfortunately something went wrong with the camera and no video.

Anyways, I know it's a bit cliche to make ingots from a muffin pan, but I did. They turned out pretty good.

I do actually have plans to melt and mold items for an actual use: casting parts for my miniature steam engine hobby. I plan on doing lost wax or PLA from 3d printed components. I don't yet have the 3D printer, so I guess that's the project.

UPDATE:

It's been a few weeks since published this Instructable. Since then I performed another melt and this time the video was successful. This melt was another candy dish and a cast aluminum mug. As I note in the video, I step over the hot lid. This was very stupid of me and I must plan better next time.

Step 15: Ruminations After the Project

So what have I learned on this project:

- It was a bit more expensive that I thought. I originally thought I could do this on about $100. In reality, I spent closer to $300 with the purality of the money going to refractory mortar. It was simply more expensive that I thought it would be. Second was the propane components, the crucible, then the steel to make the tools.

- Melting was less tricky than I imagined. I read of all sorts of issues about melting and casting aluminum. Perhaps I'm not there yet because I actually haven't created anything useful yet. Anyways, there was less anxiety and fear than I thought I would have.

- The burner worked better than I thought. From what I've read, it seems that many people start with charcoal or make waste oil burners. If it's just a hobby, I'd skip the charcoal and go straight to the propane burner. (But then if it wasn't a hobby, you wouldn't be making a furnace from an old propane tank.)

- It's clean: no ash.

- It's quick: The melt took less than 30 minutes.

- It's easy: No forced air induction so you can do this away from any building because you're not tied to an electrical outlet.