Introduction: Another MIDI Splitter

Connecting multiple synthesizers during a live session can pose many problems. Especially when dealing with a large number of devices that do not have a MIDI thru connector. When outputs are missing, a MIDI splitter must be used, which copies one MIDI output several times to several outputs. Such devices can cost a lot compared to the cost of making one. It is not difficult, all you need is a few components and little knowledge how MIDI interface works.

Supplies

Software:

- 3D drawing software (Autodesk inventor in this case)

- Slicer for 3d printing (IdeaMaker in this case)

- PCB design software (KiCad in this case)

Mechanics & tools:

- 3D printer

- Soldering station

- Screws and nuts 3M

- MIDI sockets

- Power supply socket

Electronics:

- Logical inverters

- LM7805

- Some resistors

- Some capacitors

- Circuit board

Step 1: Make Assumptions

- Eight MIDI outputs

- Standard 9V power supply (or battery)

- Small size (optional)

- 3d print enclosure

- Use elements which I find at home :)

Step 2: 3D Models

Beginnings

When I design a device, I like to have a visualization of it before it is actually created. This allows me to compare the design to the target device. So here I decided to take the enclosure as the first of the splitter components.

Of course, the enclosure itself is not everything, in order to have a full picture of the device to begin with I took to creating models of all the components such as switches, connectors and a 9V battery. I had all of these components scattered somewhere in the house so I had to break them down, measure and then draw them. I had used Autodesk Inventor software sporadically so far, so it took me some time to draw them. However, I managed to make them nonetheless :)

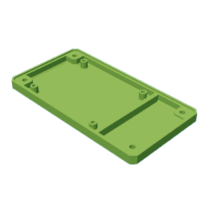

Enclosure

The case consists of two parts: the cover and the box. The box houses the signal and power connectors, and includes space for the nuts that secure the lid. The second part of the case houses the electronics and battery. The box and the cover connect using M3 screws that screw into the nuts mounted in the box. The case measures 59x109x51 mm, and contains one MIDI input, eight MIDI outputs, a 9V power input and an on/off switch. I also added captions above the switch and MIDI input. I assumed that the electronic part would fit on a 50x60mm board, which later turned out to be an elegant assumption.

3D print

The splicer was printed on a common Creality Ender 3 printer, and I set the layer thickness to 0.24mm. After printing, the enclosure looked exactly as in the visualization.

Step 3: Design PCB

How MIDI splitter works?

The operation of a MIDI Splitter, in simple terms, reduces to copying the input signal N times. Often logic gates are used for this due to the fact that we are duplicating a digital signal. MIDI interface is based on current loop transmission so each output must be connected to a separate signal output.

Design schematic and PCB

The input of the signal is separated by an optocoupler, which sends it further to the first of the gates of the inverter. Then the signal goes to the other gates duplicating nine times.

All connections to the connectors were made via a molex connector, 2.54mm raster. The schematic also has one output for an LED indicating the emerging signal. For now, it has not been provided in the enclosure, however, future versions may already have it.

I planned to etch the board myself, so I decided to use through-hole components and a single-layer laminate. This should not be a problem, as the schematic is not complicated. I used KiCad software to design the board. I assumed a single thickness of paths so as not to create problems with etching the board later. I also marked the mounting holes needed to mount the board in the case. The design from KiCad is available on the repository where the entire project is housed.

Attachments

Step 4: Assemble All the Elements

Once we have all the elements, they can be put together. In the photo you can see the result of my work. The splitter works for all devices as intended. The project can be considered completed.

Step 5: Conclusions

I realize that I have not presented many aspects of the device. While creating this project, I did not think I would want to publish the results. Hence the lesson learned - future projects occupied with more pictures! :D

![Tim's Mechanical Spider Leg [LU9685-20CU]](https://content.instructables.com/FFB/5R4I/LVKZ6G6R/FFB5R4ILVKZ6G6R.png?auto=webp&crop=1.2%3A1&frame=1&width=306)