Introduction: Checking a Radial Arm Saw for Squareness

Radial arm saws often get a bad reputation as being inherently inaccurate. But with proper set up and usage, this reputation is an undeserved slander.

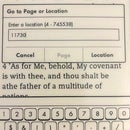

The photo shows the usual way of aligning and checking a radial arm saw for a square crosscut using a framing square. It is a good preliminary check.

The photo shows the usual way of aligning and checking a radial arm saw for a square crosscut using a framing square. It is a good preliminary check.

Step 1: Sweep Away Chips

Accurate work on a radial arm saw requires good contact between the fence and the work piece. Sweep away any dust and chips that might lodge between the work piece and the fence. Each time a cut is to be made, sweep away any dust or chips first.

Step 2: Make a Couple of Square Pieces

I have some thin plywood left over from another project. Cut two squares about 12 x 12 inches. The machine cut edge of the plywood is against the saw fence.

Step 3: Mark the Factory Edge

Before you forget, mark the factory cut edges.

Step 4: Mark the Square Corners

The square corner cut in step 2 will be the standard of reference. Mark it on both pieces so you can identify it easily later.

Step 5: Stack the Two Pieces and Cut

With the two pieces stacked over each other, trim the edge of the two pieces with one cut.

Step 6: Flip One of the Squares Over

The upper side of one of the squares will be flipped over so the edges cut in step 2 meet one another.

Step 7: Push Squares Together and Check for a "V"

With the two squares pushed firmly against the fence or any straightedge, slide them laterally into each other. Look for any spreading at the front or the rear that makes a slight "V" between the pieces. A knife edge allows evaluating how much of a "V" exists. If the "V" is at the fence, the saw arm is too far to the left. If the "V" is at the back (near the saw operator) the saw arm is a little too far to the right. The separation noted in the "V" is actually double the amount the arm is out of alignment with the fence. See also my previous Instructable on a way to make small adjustments in the alignment of the arm with the fence.

The alignment on this saw is pretty good. There may be a "V" gap of a few thousandths of an inch near the operator, but it is so small over 12 inches that glue would easily fill the gap.

This method can also be used with a table saw, especially if a sled is used in place of a miter gauge.

The alignment on this saw is pretty good. There may be a "V" gap of a few thousandths of an inch near the operator, but it is so small over 12 inches that glue would easily fill the gap.

This method can also be used with a table saw, especially if a sled is used in place of a miter gauge.