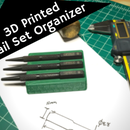

Introduction: How to Make a 3D Printed Screwdriver Caddy Using Fusion 360

I picked up this set of small screwdrivers at an estate sale and needed some way to keep them organized. Having everything rolling around loose in the drawer is getting annoying and it would be nice to keep these within reach.

I'll show you how to design and make this 3D printed screwdriver caddy. The dimensions used worked for this set of Craftsman Professional screwdrivers, and to fit on the Monoprice Select Mini 3D Printer. It is sized to fit six drivers in less than 120mm print bed.

I designed this caddy in Fusion 360 and exported the STL file to Cura. The operations we simple sketches, extrusions, fillets and chamfers. The slicer settings I used are below, and the part was printed in PLA from Matterhackers. After printing, four 6mm cylindrical rare earth magnets are pressed into the back and secured with CA glue.

Step 1: Start With a Sketch

I start every project with a sketch. Even the simplest designs can be made better and the specific details clarified by just sketching the parts out first. In this case, working out the spacing between each screwdriver slot, the overall height and overall depth were much easier on paper. You don't have to sketch to scale to work out those dimensions, but it helps.

Step 2: Create the Basic Form

Referencing the initial sketch, open up Fusion 360 and start a sketch on the XY plane. I like to start with whatever is the most basic shape, and then begin modifications from there. Once the sketch is complete, extrude it out 21mm to create the base solid body.

Step 3: Cut the Profile

With the solid body created the next step is to cut out the profile along the length. Start a new sketch on one of the side planes. This is a place to get a little artistic in the shape, and I used a large cover to cut out a curved surface. Make sure to leave enough thickness, about 7mm, for the magnet pockets that will be added at a later step. Use the extrude tool again to cut that profile out through the entire solid.

Step 4: Extrude the Holes

With the form roughed out, it's time to cut the holes that will hold the screwdrivers. Create another sketch on the top surface of the caddy, I used a circular profile with 5.25mm diameter. The holes are biased towards the front of the caddy to reduce the overall volume, filament usage and print time. Using the rectangular pattern tool, create all 6 instances of the holes, spaced 20mm apart.

The spacing was set by the size of the screwdriver handles to keep them from interfering with each other or the wall behind the caddy. The last detail, the outer two holes are set only 9mm from the edge, instead of 10mm. This let me keep the overall length of the caddy to 118mm, just small enough to fit on the 120mm print bed of the Monoprice Select Mini 3D printer.

Step 5: Cut the Pockets for the Magnets

Moving to the back side of the caddy, the next step is to cut out the pockets that will secure the magnets. I used 1/4-inch diameter by 1/4-inch tall cylindrical rare-earth magnets. The pattern is completely up to the design, I centered the pockets between the screwdriver holes to make sure there wouldn't be any interference or very thin walls. I found a diameter of 6.5mm worked well to hold the magnets with a good press fit that was still easy to assembly.

When extruding the sketch to cut the pockets, over-shoot the distance by 1mm, this was 7.5mm for my magnets. This extra millimeter of length will be taken up with a chamfer added in the last step. Putting a chamfer at both edges of the cylindrical holes serves two purposes. First, the chamfer on the leading edge will prevent any burr or flash between the part and the build surface while also making assembly of the magnets easier. Second, the chamfer at the bottom edge of the pockets will provide a nice stop for the magnet and help ensure that all four magnets are pressed into the same distance and flush with the back surface.

Step 6: Dress Up the Edges

At this point, all of the critical features are complete but the part doesn't look very nice. One of the nicest benefits of 3D printing is how easy dressing up the surfaces and edges can be without really adding any complexity to the print. Proper chamfers and fillets will also improve the quality of the print, as most 3D printers cannot create a perfectly square corner.

My order of operations was:

- 10mm fillet on the bottom corners

- 8mm fillet on the front corners

- 2mm fillet on all the top edges

- 5mm fillet on the bottom edges

- 2mm fillet around the bottom of the holes

- 1mm chamfer around the back edge

Step 7: Chamfer the Screwdriver Holes

The last operation is optional and depends on the particular screwdriver handle shape. The set I have has a generous taper and a small area where the shank exits the handle. Instead of sitting on the handle surface, I wanted to recess the drivers into the caddy slightly to keep them from rattling.

Add one last chamfer, with unequal legs, around the top edge of the screwdriver holes. In my case, this chamfer was 1mm on the top edge and 8.5mm down the hole. Finally, a small 1mm fillet dresses that top edge of the hole.

Step 8: Let's Print It!

The model is now complete and exported from Fusion 360 as an STL file. I'm still using Cura 15.04.06 for slicing. My slicer settings are shown below, and the print time was about 2.5 hours.

Print and Slicer settings were:

- Layer Height: 0.21875mm

- Shell Thickness: 0.8mm

- Infill: 18%

- Extrusion Temp: 195c

- Bed Temp: 45c

Step 9: Glue the Magnets In

After printing, remove the part from the print bed. No support material is required, so there's really no clean up after printing. Flip the part over, and a small dot of CA glue in each of the magnet holes will secure them. The press fit is tight, but not too tight to assembly with just your thumb.

Step 10: The Finished Product

Thanks for reading!

I hope you enjoyed this quick tutorial on Fusion 360 and how to design functional 3D printed storage solutions. If you want to see more of what I’m working on, check out the links below.

See you next time.

-------------------------------------

You can also find me at:

YouTube (all my DIY videos)

Instagram (What I'm working on @greatlakesmakes)

My Website (Geek out on some engineering know-how)

Facebook (be my friend?)

My Mini Factory (download the STL files)

-------------------------------------