Introduction: Keyhole Saw Handle From Pipe

The photo from Google Images shows a keyhole saw with a plastic handle. I had a similar plastic handle on my saw and it broke. I made a replacement with a piece of pipe.

Step 1: Mark the Pipe for Length

You can see the blade pattern on my saw. Once all keyhole saw blades had this configuration.

I am using 1/2 inch black iron pipe. I wrapped it with masking tape for easier marking. The handle needs to be long enough for both the blade and my hand.

I am using 1/2 inch black iron pipe. I wrapped it with masking tape for easier marking. The handle needs to be long enough for both the blade and my hand.

Step 2: Cut to Length

After marking, cut the pipe to length. I like to use an angle head grinder with a thin kerf cutting blade.

Step 3: Mark for the Blade Slot

Masking tape works well for marking a slot for the blade. Make the slot just a little longer than the width of the blade. I put the pipe in a vise and used the vise jaw as a marking guide.

Step 4: Cut the Blade Slot

The cutting wheel is just a bit thicker than the saw blade and makes a kerf just the right width.

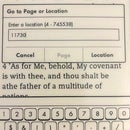

Step 5: Handle Angle

Put the blade into the slot and decide on a comfortable angle for holding the saw handle. Mark it with a "T" bevel square.

Note: I thought I would go to a store and buy a spare blade for my keyhole saw. Once that was very much possible. But, it is almost impossible to find a keyhole saw or blades for one now. So, I found a way to adapt blades for a reciprocating saw popular with contractors to fit this saw handle. That allows me to use wood or metal cutting blades in my saw. It also allows me to use a blade for cutting on the push or on the pull stroke. This makes a very handy saw to take with you when, for example, you need to cut something to length quickly so it will fit into your car.

Note: I thought I would go to a store and buy a spare blade for my keyhole saw. Once that was very much possible. But, it is almost impossible to find a keyhole saw or blades for one now. So, I found a way to adapt blades for a reciprocating saw popular with contractors to fit this saw handle. That allows me to use wood or metal cutting blades in my saw. It also allows me to use a blade for cutting on the push or on the pull stroke. This makes a very handy saw to take with you when, for example, you need to cut something to length quickly so it will fit into your car.

Step 6: Mark Strap Iron

Place a piece of masking tape on a piece of 1/8 x 3/4 inch strap iron and mark the angle you set with the "T" bevel square. The mark is about 1 1/2 inch from the end of the steel. Cut on the mark.

Step 7: Cut the Steel to Make a Second Piece

Use the first piece of steel to mark the length of the second and cut. Grind away any sharp edges.

Step 8: Clamp and Drill

Clamp the two pieces of steel together and drill a 1/4 inch hole as shown.

Step 9: Sandwich for Tack Welding

Use a 1/4 inch bolt and nut to make a sandwich of the two pieces of steel and the blade. Insert into the blade slot you cut into the pipe. Tack weld the pieces of steel to the pipe. Weld each side, but be careful not to weld the saw blade into the handle accidentally.

Step 10: Add a Finger Guard

Your fingers need some protection from the sharp teeth. Weld a piece of 1/8 x 1/2 inch steel to the pipe as shown. Tighten the bolt and nut. Your saw handle is ready to use.

Step 11: Hole for Hanging

Pinch the saw handle with your thumb and first finger to find the balance point at which the blade hangs straight down. Drill a hole through the handle so you can hang the saw on a pegboard rack. You are now finished.