Introduction: Minimalist USB Connector - No Special Hardware Required

Many times, while making some DIY project or another, I've found myself in need of a USB Connector. However, I could never find a guide on how to make one without custom parts or expensive machinery. So, I decided to design and make one myself.

Supplies

- 24-gauge solid core copper wire or similar

- Wire strippers

- Needle-nose pliers

- Hot glue (preferable) or tape

- 3D printing capabilities - a personal 3D printer & slicer or access to a 3D printing service

- Sandpaper (for post-processing the print - may not be necessary)

- Both STL files attached below.

Note: If you are printing this yourself, the print requires approximately 1.3 meters of filament, or 4 grams.

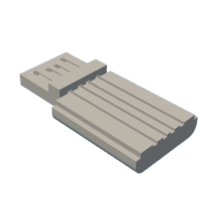

Step 1: Design

I designed the connector in Fusion 360, using the measurements found in the USB 2 Series "A" specifications. The specifications can be found here:

https://www.usb.org/document-library/usb-20-specification

I added small holes to the front of the plug, so that the bare wires could slip into the holes and would not bend upwards when the plug was inserted into a USB port. I also added teeth to the top of the connector, so that it would hold the wires firmly in place once it was attached.

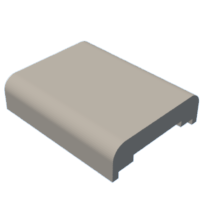

Step 2: Print

After designing the connector, I printed it in the orientation shown above with supports and full infill. Note that you will need to print both STL files: one is the top and one is the bottom. I used Inland Silver PLA at a temperature of 205 C, but obviously the settings will vary greatly depending on filament and printer.

After the print was completed, I gently removed the brim and sanded away any rough edges. My printer is calibrated well enough that the USB plug fit snugly into a USB port. If it does not, however, gently and symmetrically sand away at the edges of the plug until it does.

Step 3: Insert the Wires

First, I stripped each wire so that the exposed wire was the length of the plug. This turns out to be about 1.3 cm, but it's easier to just compare the wire and the plug. After stripping the wire I inserted it into the plug.

After inserting the wire, I bent the very tip of the wire down about 30 degrees using the needle-nose pliers. Then I pulled the wire back so that the bent tip was over the hole in the connector, and gently guided the wire into the hole, using my fingernail to press it in firmly. I repeated this process with the next 3 wires.

Note: I've found that it's easier to put all 4 wires through the plug and then guide all 4 in at once.

Step 4: Securing the Top

I gently pushed on all four wires to ensure that they were in place. Then I applied a glob of hot glue onto the wires, making sure to cover all of them, after which I pressed the top down firmly while I waited for the glue to cool. If you do not have access to hot glue, you can firmly (very firmly) wrap tape around the outside of the connector to hold it together, but hot glue will perform better.

Step 5: Use!

As you can see in the above image, this USB port will properly connect to standard USB ports -- in that image I have connected it to a generic USB charger, and the voltmeter indicates a complete circuit.

This little plug is quite versatile. It fits into any standard USB port, and thus has as many uses as the USB itself, including custom power supplies, breadboard interfacing, and repairing existing USB cables. Best of all, it's simple, practically free, and anyone can make it - no special hardware or laser-cutters required!

Participated in the

Digital Fabrication Student Design Challenge

![Tim's Mechanical Spider Leg [LU9685-20CU]](https://content.instructables.com/FFB/5R4I/LVKZ6G6R/FFB5R4ILVKZ6G6R.png?auto=webp&crop=1.2%3A1&frame=1&width=306)