Introduction: Particle Accelerator Demo

A while ago I decide to try to make a simple demo of particle accelerator, and I finally managed to do it. In this Instructable I will show you step by step how to make it.

Before we start, let me explain briefly how particle accelerators work and what is the role of electric and magnetic filed in them.

Particle accelerators use electric fields to speed up and increase the energy of a beam of particles, which are steered and focused by magnetic fields. The particle source (hydrogen gas for example) provides charged particles (protons or electrons), that can be accelerated. The beam of particles travels inside a vacuum in the metal beam pipe. The vacuum is crucial to maintaining an air and dust free environment for the beam of particles to travel unobstructed. Electromagnets are used to steer and focus the beam of particles while it travels through the vacuum tube and collide them at designated detector.

In other words the electric field is used to accelerate particles (speed them up) and magnetic field is used to bend and steer them. It is worth mentioning that for the accelerators to work the particles must have an electric charge (positive or negative). Neutron for example, don't have an electric charge therefore they can't be accelerated by electric filed.

My simple demo accelerator works slightly differently. As it is difficulty to produce charged particles out of hydrogen gas at home, I decided to try slightly different approach. Instead of charged particle I used magnetic ball bearing and instead of electric filed I used electronic circuit to vary the magnetic filed produced by two coils. Once the electronics is switched on, the magnetic ball bearing will start moving inside circular track and accelerating it until it finds an equilibrium. At that point magnetic sphere will move with constant speed.

Supplies

- 1x 9V battery with battery clip

- 8mm magnetic sphere (10mm is fine if you scale 3D model model by 10%)

- 1x 1000uF electrolytic capacitor

- 1x 1MOhm potentiometer

- 2x 100kOhm resistors

- 1 x 100Ohm resistor

- 1 x 1kOhm resistor

- 1 x 12kOhm resistor

- BC558 PNP transistor

- BC337 NPN transistor

- BD135 NPN transistor

- 1x 3mm Red LED

- 1x PCB on/off switch

- Prototyping strip board (PCB for etching is optional)

- PLA (3d printing material)

- 2x M3 x 15mm screw with nut

- Equipment wire

- Solder

Tools:

- Wire strippers/cutters

- Soldering iron

- FDM 3D printer

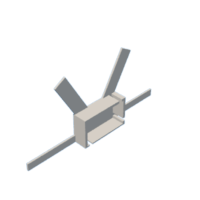

Step 1: CAD Design and 3D Printing

I made this model in Fusion 360 which is my favorite CAD software. I made few versions of this demo accelerator and I was playing with the numbers of coils around the circular track and the dimeter of the track itself.

As it turns out 2 coils opposite each other, work the best for the 160mm diameter track. If you decide to modify my model and make larger track I would suggest to add another coil.

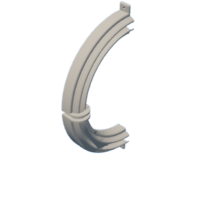

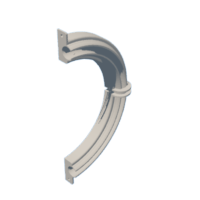

For printing and slicing I would recommend to use Cura, but if you have your favorite slicing software that works, there is no reason not to use it. I printed model in PLA, no brim or raft and 25% infill. It takes about 6-8 hours to print all parts with 0.2mm layer resolution, but that depends on the speed of your printer of course.

Instead of PLA you can of course use other printing materials like PETG, ASA or ABS, but I find PLA, especially Polymaker brand really good for my home made 3D printer.

Step 2: Electronics

Above you can see circuit diagram that will drive our demo accelerator and pinouts of all crucial parts.

When magnetic sphere has enough speed it will induce a voltage in the coil. This spike goes from the coil through the 100k resistor to the base of the PNP transistor. Opening the PNP and therefore opening the NPN transistor which powers the coil, giving the magnetic sphere a push in the same direction, therefore accelerating the ball.

For this project I used the prototyping strip board as it's not very complicated circuit and you can solder all components fairly quickly. If you like to make proper PCB, below you will find pdf documents with the traces that you can use for etching PCB. Another option is to use mini CNC milling machine to manufacture PCB, if you have access to one.

NOTE: There are few standards when it comes to transistor pinouts. It all depends where manufacturere is based.

Japan - ECB

America - EBC

Europ - CBE

Attachments

cyclotron coil v1_etch_mask_bottom_mirror.pdf

cyclotron coil v1_etch_mask_bottom_mirror.pdf cyclotron coil v1_etch_silk.pdf

cyclotron coil v1_etch_silk.pdf cyclotron coil v1_etch_mask_top_mirror.pdf

cyclotron coil v1_etch_mask_top_mirror.pdf cyclotron coil v1_etch_mask_top.pdf

cyclotron coil v1_etch_mask_top.pdf cyclotron coil v1_etch_copper_bottom.pdf

cyclotron coil v1_etch_copper_bottom.pdf cyclotron coil v1_etch_copper_bottom_mirror.pdf

cyclotron coil v1_etch_copper_bottom_mirror.pdf cyclotron coil v1_etch_mask_bottom.pdf

cyclotron coil v1_etch_mask_bottom.pdf cyclotron coil v1_etch_copper_top.pdf

cyclotron coil v1_etch_copper_top.pdf cyclotron coil v1_etch_copper_top_mirror.pdf

cyclotron coil v1_etch_copper_top_mirror.pdf

Step 3: Assembly

Once you 3D print the accelerator ring, you then have to wind the coils. I recommend to use 25 SWG enameled copper wire and do 100 turns on each coil. Once you have your coils ready, connect them in series to the electronics that you have prepared in previous step (see the circuit diagram in previous step).

Place the 9V battery and strip board with electronics in the middle of the accelerator in dedicated slots. Then insert 8mm magnetic sphere inside the track and put two semi-circular parts together. Use M3 screws to join the two parts permanently and make sure that the sphere can move freely (without too much friction) inside the track.

Step 4: Testing

You are now ready to test your accelerator. To do that switch on the electronics and tilt the device to move the magnetic ball close to one of the coils.

The magnetic ball should start to oscillate. Once the coil will give the ball proper push you can then place the device back on level ground. The magnetic sphere should start moving inside the circular track and accelerating very quickly. At some point it will reach the equilibrium and the ball will keep circulating with constant speed.

You can play with the potentiometer to vary the frequency of the variable magnetic filed of the coils to see if you can speed up, or slow down the magnetic ball. If you find the right frequency, the ball can move pretty fast :)

Slow motion video:

First Prize in the

STEM Contest