Introduction: Proxxon Micro Mill Semiautomatic-CNC

Hello! I’m a junior high student and this is my arduino project. This is an instruction about modifying proxxon mf-70 from full manual into semi-automatic. If you’re interested, please watch the video!

Video:

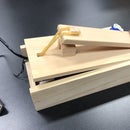

Step 1: Control Board-1

Material

- Aluminum (100x80x1mm)

- Wood board (120x200x12mm)

- Push switch

Tools

- Chisel (12, 30mm)

- Handsaw

- Jigsaw

- Drill

Method

Aluminum board

- Draw mark for inserting the push switches

- Drill hole that fits the push switches

Wood board

- Use hand saw to cut the wood board into the size of

- Draw lines for inserting the aluminum board and LCD screen

- Use jig saw to saw out the lines

- Use 30mm chisel to make the side smoother

- Use 12mm chisel to cut out notch that can fit the LCD screen (like the picture above)

- Use 12mm chisel to cut out a slope at the edge of the LCD screen area (like the third picture above)

Step 2: Control Board-2

Material

- Led(Red and Green)

- LCD board https://www.amazon.com/SunFounder-Serial-Module-D...

- Screw m3

- Keypad (4x4) https://www.amazon.com/Matrix-Membrane-Switch-Key...

Tools

- The same

- Screwdriver

Method

Aluminum board

- Drill two more holes to place in the LEDs

- Insert it by placing it inside if it fits and not loosely or glue it on the wood

LCD screen

- Place the LCD board in the wood board

- Screw (like the picture above)

Key pad

- Drill holes in a line on the area that the wire has to go through

- Use 12mm chisel to make it square

- Make the wire go through the back of the wood board

- Wrap off the white layer of the key pad

- Stick it on the wood board

Step 3: Control Board-3

Material

- Arduino Nano

- Jump wires

- Breadboard

- Computer (downloaded Arduino)

Method

- picture above

Circuit

- Picture above

- LCD i2c (SDA-A4)black

- LCD i2c (SCL-A5)blue

- LCD i2c (VCC-5v+)red

- LCD i2c (GND-GND)black

- Push switch1 (the right one above the green LED-D13)green

- Push switch2 (the one at the left of this one↑-D11)Red

- Red LED (connect with the push switch2)

- Green LED (connect with the 5v+)

- Keypad (connect from D10 to D3)

Program

Step 4: Proxxon Micro Mill — Material

Material (for each axis)

- Thrust bearing x1 https://goods.ruten.com.tw/item/show?217422420585...

- Bearing adapter x1 (Pre-processing)

- Diameter 2mm axle x1

- Axle adapter 4.5-5mm x1

- Stepper motor x1 https://goods.ruten.com.tw/item/show?214051710720...

- Stepper motor adapter x1 (Pre-processing)

- m3 screw x3

- Copper pillar x3

- M3 Spacer x3

Tool

- Hex key (

- Vernier scale

Step 5: Pre-processing

Method

Stepper motor adapter (for x and y axis)

- Combine two cut 3mm acrylic board (design page dxf(1))

Disassemble the handle (x and y axis will be mostly the same)

- Unscrew the screw

- Remove the dial scale (there’s a small pin will pop out)

- Use a 1.9mm pin and a hammer to knock the pin for connecting the handle out

- Remove the black plate (pic 7)

- Drill three holes on it for connecting stepper motor (only for z axis)

Cutting the stepper motor axle (the shortened length will be different for x, y, z axis)

- Measure the length of the axle that has to be shortened (Mark it with marker)

- Use tape to protect the motor from the dust

- Use grinding wheel to cut the axle (wear gloves)

Cutting the copper pillar

- Measure the length of the copper pillar that has to be shortened (Mark it with marker)

- Use grinding wheel to cut the copper pillar (wear gloves)

Thrust bearing adapter (design page 3dm(1))

- Use CNC to mill aluminum to form the shape

- Mill a trench for fitting a 2mm pin (2mm mill head)

Step 6: X-axis

Method

- Screw the copper pillar on the stepper motor(do not screw it too hard)

- Screw the stepper motor adapter onto the three copper pillar with 3 m3 screws (the screws might have to be cut shorter to fit)

- Screw the axle adapter on the stepper motor axle (make sure it’s screwed on the flat surface of the shape axle)

- Insert the thread bearing onto the bearing adapter

- Screw the stepper motor adapter on the mill with two m3 screw

- Screw the axle adapter on the mill axle

Step 7: Y-axis

Method

- Screw the copper pillar on the stepper motor(do not screw it too hard)

- Screw the stepper motor adapter onto the three copper pillar with 3 m3 screws (the screws might have to be cut shorter to fit)

- Screw the axle adapter on the stepper motor axle (make sure it’s screwed on the flat surface of the shape axle)

- Insert the thread bearing onto the bearing adapter

- Screw the stepper motor adapter on the mill with two m3 screw

- Screw the axle adapter on the mill axle

Step 8: Z-axis

Method

- Screw the copper pillar on the stepper motor(do not screw it too hard)

- Screw the copper pillar on the black plate

- Insert the thread bearing onto the bearing adapter

- Screw the axle adapter on the stepper motor axle (make sure it’s screwed on the flat surface of the shape axle)

- Screw/unscrew the hex nut on the z-axis thread in order to adjust the position of the hex nut (Before the black plate was screwed on the mill

- Screw the black plate on the mill

- Soldering the stepper motor 4 line wire (If the order is incorrect)

Step 9: Stepper Motors Protection Cover

Method

- Use laser cutter to cut the acrylic in shape (Design page dxf(2))

- Use clamps to hold the acrylic (picture 5, 6, 7, 8, 9)

- Heat the acrylic with a heat blower (picture above)

- Drill two holes on one side on the acrylic (picture 11)

- Screw m3 screws on the acrylic with hex nut

- Attach the protection cover on the x, y axis (picture 14, 15, 16)

Step 10: Arduino + CNC Shield

CNC sheild https://goods.ruten.com.tw/item/show?2172447624178...

Connect Arduino uno with CNC shield

How to connect two Arduino

- connect Arduino nano tx to Arduino uno rx

- connect Arduino nano rx to Arduino uno tx

- Share the same GND

Step 11: Designs

File:https://drive.google.com/open?id=1sYZMpM7S5FVr36sa...

3dm files:

- axle adapter (for cnc)

- Whole layer (how to assemble layer1 and layer2)

dxf files:

- layer 1 (stepper motor adapter)

- layer 2 (stepper motor adapter)

- stepper motor protection cover

Step 12: How to Use the Control Board

How

- Push switch 2(above the red LED) Change mode:On-mode 2, Off-mode 1

- Mode 1

- A: x-axis

- B: y-axis

- C: z-axis

- *: move— +the variable

- #: move— -the variable

- 0: reset the coordinate to (0, 0, 0)

- 1: move 0.1mm

- 2: move 1mm

- 3: move 10mm

- Mode 2

- A: Feed rate

- B: Show coordinate

- Number key(has to push the push button 1(above the green LED) to key): key feed rate

- *: clear the feed rate

video: