Introduction: Ramps for a Low Car

My car is too low for steel auto ramps. The cowling under the bumper touches the ramps before the wheels do. I made my own ramps from 2 x 8 lumber.

Step 1: Determine the Dimensions

I needed to know the angle of the ramps' incline and the length of the incline. I used a block and a piece of 1 x 6 lumber. The 1 x 6 clears the cowling under the front bumper with a little to spare. My old ramps were 8 1/4 inches high where the wheel rested. I would like to duplicate that on these ramps. The base of the incline needs to be about 30 inches long (yellow tape measure).

Step 2: Materials

I bought two 2 x 8 boards twelve feet long and cut them to make four boards six feet long each. I also bought an eight foot board (2 x 8). I cut it to six feet in length. Clamp the boards so the rings are set opposite one another. I also used two smaller pieces of 3/4 inch stock and some long drywall screws (2 1/2 to 3 inches). The high-tech version of these ramps uses a circuit activated by the pressure of the car's wheel to light a small lamp. This tells the driver when the wheel is in the proper position on the ramp.

Step 3: Mark the Line for the Incline

I measured 15 inches in from each end and marked a straight line between the blue arrows. This marks the incline on the two ramps and gives an incline the proper length according to step 1. Turn the clamped assembly over and make an identical line on the other side. Make certain the lines are parallel to one another and do not cross each other to form an "X".

Step 4: Screw Together

Mark the five boards to know their order in the stack. Begin screwing them together with long drywall screws. The line for the incline is between the two blue arrows. The assembly will be sawed apart later. Place the screws so none cross the incline line. You do not want to saw through screws later.

Step 5: Begin Sawing

The assembled boards are 7 1/2 inches high. My saw cuts only a bit over two inches in depth. Begin by cutting as deeply as possible on the incline line from both sides. (This will leave almost 3 inches between the two cuts you cannot reach. There is more about this later.) Begin sawing on the broad flat area in the middle and saw out toward both ends. Follow the line by your eye. That is sufficient.

Step 6: Electric Chainsaw

I used an electric chainsaw to finish separating the two ramps. It is crude, but it works fine for this application. Do your best to keep the blade guide at a right angle to the top surface.

Step 7: Add 3/4 Inch in Height

Five boards stacked gives about 7 1/2 inches in height. I added a piece of 3/4 inch plywood to reach the desired 8 1/4 inches in height. It did not need to be six feet long, but only needed to cover the area where the wheel will rest on each ramp.

Step 8: Cut the End to Fit the Incline

I wanted to extend the incline's plane through the 3/4 inch top piece. I used a rotary planer attachment on my radial arm saw. The rotary planer attachment has three carbide tipped cutters. The cut is a little rough, but would smooth nicely with a little sanding, if a finished surface were needed. The angle of the incline is about 12 degrees. Light cuts are best to control pulling of the work by the planer attachment. Cuts can be adjusted by sliding the work toward the cutters or by lowering the radial arm saw's arm.

When finished, use shorter drywall screws to attach the 3/4 inch piece to the rest of the ramp.

When finished, use shorter drywall screws to attach the 3/4 inch piece to the rest of the ramp.

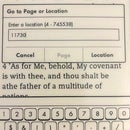

Step 9: Judging When to Stop

Driving a car onto a set of ramps without an assistant to serve as a spotter can make a person nervous. If you overshoot, you can do serious damage to the sheet metal on your car. I decided to go high-tech and use an electric bulb turned on by the pressure of the wheel when it is in its proper place.

I settled on building a cage and actuating lever for a momentary contact switch I already had. The switch (A) is normally "open" until depressed. The cage for the switch is welded from 3/4 inch square steel tubing. The actuating lever (B) is hinged (C). The spring in the switch is enough to lift the actuating lever. I did not want the small switch to bear the weight of the front wheel, so I added a steel stop (D). There was a little fitting to make everything work properly. This switch cage will be buried in a recess cut into one of the ramps.

I settled on building a cage and actuating lever for a momentary contact switch I already had. The switch (A) is normally "open" until depressed. The cage for the switch is welded from 3/4 inch square steel tubing. The actuating lever (B) is hinged (C). The spring in the switch is enough to lift the actuating lever. I did not want the small switch to bear the weight of the front wheel, so I added a steel stop (D). There was a little fitting to make everything work properly. This switch cage will be buried in a recess cut into one of the ramps.

Step 10: Inlet for the Switch Cage

I used a bandsaw to cut an opening for the switch cage in the 3/4 inch plywood top for one of the ramps. I needed to remove some material in the top piece of two inch lumber for a proper fit.

Then I drilled down into the ramp about one inch so the hole is under the terminals on the momentary contact switch. I drilled in from the side of the ramp so I could feed two wires to the switch.

Then I drilled down into the ramp about one inch so the hole is under the terminals on the momentary contact switch. I drilled in from the side of the ramp so I could feed two wires to the switch.

Step 11: The Circuit

The circuit is a simple series circuit for a bulb, a switch, and a power supply. The power supply is a car charger for a cell phone we no longer have. It plugs into the cigarette lighter and gives 5 volts at around 1/2 amp. I found a flashlight bulb rated at 4.75 volts and 0.5 amp, which is perfect.

Step 12: Using the Bulb System

I have about fifteen feet of two stranded wire coming from the switch embedded in the ramp on the driver's side of the car. It is enough to come through the window on the car door. The phone charger plugs into the cigarette lighter. When the wheel presses on the switch cage, the bulb on my lap lights and I know to stop.

The phone charger (A) is plugged into the cigarette lighter. The bulb (B) is lighted. When the bulb lights and the wheel is in its proper place, pull the charger from the lighter and the circuit is "off." Check to be certain the bulb will light before driving onto the ramps. There is also a different feel when the wheel moves from the incline to the flat part of the ramps.

Another way to judge when to stop would be to measure from the center of the front wheel back to the car's door handle. Measure this distance from the center of the area where the wheel will rest on the ramp back toward where you will sit when driving the car onto the ramps. Place an upright thin pole at that point. When the pole is even with the car's door handle, stop.

I had some extra two inch stock. I cut two pieces and screwed them vertically to the ends of the ramps to give myself just a little more space for the wheel to rest.

The phone charger (A) is plugged into the cigarette lighter. The bulb (B) is lighted. When the bulb lights and the wheel is in its proper place, pull the charger from the lighter and the circuit is "off." Check to be certain the bulb will light before driving onto the ramps. There is also a different feel when the wheel moves from the incline to the flat part of the ramps.

Another way to judge when to stop would be to measure from the center of the front wheel back to the car's door handle. Measure this distance from the center of the area where the wheel will rest on the ramp back toward where you will sit when driving the car onto the ramps. Place an upright thin pole at that point. When the pole is even with the car's door handle, stop.

I had some extra two inch stock. I cut two pieces and screwed them vertically to the ends of the ramps to give myself just a little more space for the wheel to rest.