Introduction: Wacky Wire Carnival Game

Why did I make this game?

We have a ministry here in Mexico. We work with an indigenous people group called the Tarahumaras. We specifically focus on the children. A while ago we decided to host a carnival for all the kids and I was put in charge of making this game. It turned out great! The kids loved it even though they found it difficult. I wish I would have taken photos of it in use however the Tarahumara people are very uncomfortable around cameras so I wasn't able to take any good photos or videos.

The Design Process:

For the entire process of designing and building this game, I used Fusion360. If you want to see the full modeling process you can open the provided .f3d file and see the entire design process from start to finish.

Table of Contents:

- Step 1 Wiring

- Step 2 Bending the Wacky Wire

- Steps 3-5 Assembling 3D Printed Parts

- Step 6 Handle

- Step 7 Wooden Structure

- Step 8 Final Assembly

Print Files:

I have included the correct files on each step, however, the full assembly and .f3d files can be found on Printables.com.

The Print files can be found here

Disclaimer:

You may wonder why all these parts seem very scuffed and torn apart. As I was in a time crunch I didn't have time to reprint all the parts to get the perfect fit, so I had to cut some pockets, drill some holes, etc... But the files I included are edited and the fitment is perfect. I just haven't had the time to reprint everything.

Supplies

Overview:

The tools needed are just basic wiring tools, basic woodworking tools, and a 3d printer. I have included all the specifics however chances are you already have many of these items.

Tools Needed:

- 3D Printer

- Drill

- Phillips Bit and a few Drill bits

- Circular Saw, Handsaw, Table Saw, or Jig Saw. Anyone works

- Soldering Iron

- Allen Keys

- Welder (Optional)

- Electrical Tape

- Sharp Knife or Scissors

- Wire Strippers and Cutters

Hardware Needed:

- 11 M4 Bolts Short (Medium)

- 10 M4 Threaded Inserts (Short)

- 1 M4 Nut (For Contact Terminal)

- 5 M3 Bolts (Medium)

- 5 M3 Threaded Inserts (Short)

- 2 M2 Bolts Long (For Mounting DC motor)

- 2 M5 Bolts (1 Long, 1 Short)

- 2 M5 Threaded Inserts (Short)

- Lots of Wire

- Solder

- Shrink Wrap

- 5mm Rod (Used as the Wacky Wire)

- 3 Bearings (10mm OD, 5mm ID, 4mm Width)

- Large 3/8in Bolt (Optional)

- Large 3/8in nut (Optional)

- 1 2x4" of Wood

- 1 4x8' sheet of plywood 1/2in thick

- 1 4 Hole Bracket, Can be found at many Hardware stores

Electronics Needed:

- 10 kΩ Potentiometer

- 2000 uF Capacitor

- Red LED

- nMOS Transistor (MOSFET)

- batteries, AA

- On-Off Switch

- GM9 Geared DC Motor

- 1 MΩ Resistor

- 470 Ω Resistor

- Piezo Buzzer

Step 1: Wiring

How to Wire this Project:

The wiring may seem daunting at first. But the circuit is straightforward. There are many different ways to wire this. Some may find it easier to use an Arduino, while others rather not have to deal with a microcontroller. This part is entirely up to you, and both have Pros and Cons. I opted to make my circuit without a microcontroller. I have included a link to the Tinkercad circuit design so you can play with it and understand how it works. I also provided a link for a tutorial on how to wire the motor controller as it can be a little difficult to understand.

Motor Controller Circuit Explanation

Basic Circuit Connections:

The 2nd and 3rd images show the motor circuits. The 2nd image is just the basic circuit, whereas the 3rd image includes a switch and an LED to indicate power. I would highly recommend looking at the images provided, the main circuit, and the links I provided above to understand the pinouts. But here is a basic pinout for the main circuit:

MOSFET Connections:

- Gate Pin (The Left Pin): Connected to the Wiper Pin (Middle Pin) Of the Potentiometer. Connected to the 1m Resistor(The 1m resistor is connected to the negative terminal on theBattery Box)

- Drain Pin (The Middle Pin): Connected to Side B of the Switch. (The Switch is connected to the positive terminal on the Battery Box)

- Source Pin (The Right Pin): Connected to the positive terminal on the Motor

Potentiometer Connections:

- Terminal 1 (The Left Pin): Connected to the negative terminal on the Battery Box.

- Wiper Pin (The Middle Pin): Connected to the gate pin on the MOSFET (Mentioned in the "MOSFET Connections)

- Terminal 2 (The Right Pin): Connected to 470ohm Resistor. (The 470ohm resistor is connected to Side B of the Switch)

LED Connections:

- Cathode (The Short Pin): Connected to the negative terminal on the Battery Box

- Anode (The Long Pin): Connected to the Side B of the Switch

Switch Connections:

- Side A: Connected the positive terminal on the Battery Box

- Side B: This is where all of the connections to the Switch mentioned above actually connect to.

Motor Connections:

- The Positive Terminal: Connected to the source pin of the MOSFET

- The Negative Terminal: Connected to the negative terminal of the Battery Box

Buzzer Connections:

- Negative Terminal: Connected to the Handle, Connected to the negative terminal of the Capacitor (The wire that connects to the Handle needs to be around 6ft long)

- Positive Terminal: Connected to Side B of the Switch, connected to the positive terminal of the Capacitor (Remember this wire has to be 2.5-3 ft long)

Wacky Wire Connection:

- The Wacky Wire is connected to the negative terminal of the Battery Box (This is done by utilizing one of the holes in the metal four-hole bracket, See more in step 8)

Important:

The wiring diagram includes two circuits. The buzzer and motor circuits. The motor circuit is fully housed inside the Electronics box. The buzzer circuit is housed inside the Buzzer Box. Two wires connect the circuits. The positive wire from the battery box goes directly to the positive terminal on the capacitor in the buzzer box. Then a ground wire directly from the battery connects to the "Wacky Wire". Then the handle is attached to the ground terminal on the capacitor via a wire. This way when the handle makes contact with the "Wacky Wire" the current passes through which triggers the alarm. Again this is all explained in the TinkerCad Circuit. (See step 8 to see how the ground wire attaches to the Wacky Wire)

Attachments

Step 2: Bending the Wacky Wire

Please Watch the Video

I was not able to document this process very well, but the video explains everything you need to know before bending the wire.

The Bending Process:

If the 5mm rod you bought is for some reason hardened, then it is necessary to do hot bends. This means using a torch to heat the metal and bend it. Try your best to avoid this!

The 5mm rod should be easily bendable by hand. If necessary you can use hammers, vices, pliers, etc...

Try and make some coils, twists, turns, etc... Make it interesting. This step is totally up to you and your preferences. But here are some tips to keep in mind:

- Keep the two ends of the wire in the same axis (So that one end isn't offset from the other, this will cause wonky movement, rather than the desired "wacky" movement)

- Keep the center of mass in line with the main axis (This means you don't want a bunch of weight on the bottom and none on the top, because then the rolling motion will start slipping and causing problems. You can test this by holding the two ends of the wire and seeing if one side always rolls to the bottom, then bend accordingly. You want to look for a nice smoothing rolling motion with no biases)

- Don't make the coils too tight (Me and my dad got too ambitious with the coils and made them way too tight, which made it nearly impossible to finish, so start easy. You can always go in and add more bends later)

Step 3: Assembling the Main Roller

Materials:

- 5 M3 Bolts (Short)

- 5 M3 Thread Inserts (Short)

- Electrical Tape

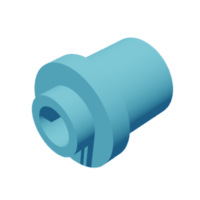

- Main Roller Hub (3D Printed)

- Main Roller (3D Printed)

Process: (Follow the Order of the Images)

- Install all of the threaded inserts into the 5 recessed holes in the Main Roller Hub

- Bolt the Main Roller into the Main Roller Hub with the 5 M3 Bolts

- Use the Electrical Tape to wrap around the channel on the Main Roller in order to improve its grip (Cut of the excess with a knife)

- Finally, insert the 5mm Wacky Wireinto the Main Roller Hub. It should be a very tight fit

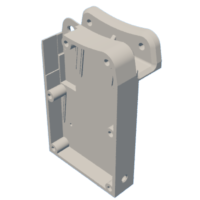

Step 4: Assembling the Electronics Box

Materials

- 6 M4 Bolts (Short)

- 6 M4 Threaded Inserts (Short)

- 2 M5 Bolts (1 Short, one Long)

- 2 M5 Threaded Inserts (Short)

- 2 M2 Bolts (Long)

- Electrical Tape

Before Assembling Read This:

The circuit I linked up above is two circuits. The motor circuit and the buzzer circuit. This electronics box is meant to house only the motor circuit. The last step in this process involves routing two wires out of the box. These wires are positive and ground that are directly connected to the battery and the switch.

Process: (Follow the Order of the Images)

- Install the two M5 Threaded Inserts into the lip of the Electronics Box (Look at the 3rd image)

- Install the 6 M4 Threaded Inserts into the corresponding lid mount holes on the Electronics Box (See 4th image)

- Install the 3 10mm Bearings into the corresponding spots on the two rollers (See the 5th image)

- Wrap the Motorized Roller with electrical tape to improve its grip

- Place the Motor in its corresponding place in the Electronics Box, then screw it in using two M2 bolts.IMPORTANT: When installing the motor be sure to insert the Motorized Roller in the correct spot before screwing in the motor, or else you won't be able to install the roller. (See the 7th and 8th images)

- Secure the Motorized Roller with the short M5 bolt(see the 9th image)

- Secure the second Roller using the long M5 bolt (See the 10th image)

- Install the electronics. The LED, potentiometer, and switch all have dedicated spots. The switch snaps into place, the potentiometer gets bolted into place using the hardware it came with (Bolt using the threads on the shaft and the provided nut). And the LED gets glued in place using the LED Mount. (See the 11th and 12th images)

- Make sure all the electronics are inside the box, and fit nicely (See the 13th image)

- Before bolting the lid on, make sure to pull out the positive and ground wires for the buzzer circuit(See the 14th image)

- Bolt the Electronics Lid in place using six M4 Bolts

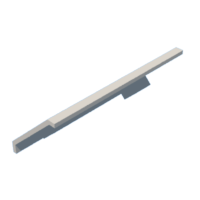

Step 5: Assembling the Buzzer Box

Materials:

- 4 M4 Bolts (Short)

- 4 M4 Threaded Inserts (Short)

- Electrical Tape

Process: (Follow the Order of the Images)

- Install the four M4 Threaded Inserts in the correct holes on the Buzzer Box. (See the 2nd image

- Insert the LED Bar and the Buzzer into the correct spots. (See the 3rd and 4rth images)

- Place electrical tape onto the open terminals of the buzzer just to stop any potential short-circuiting. (See the 5th image)

- Route the Positive wire (From the Electronics Box) Through the hole on the right side and wire that into the circuit. And route the Ground wire (From the handle) into the circuit through the left side. (See te 6th and 7th images)

- Bolt the Lid on using four M4 Bolts

Step 6: The Handle

Materials:

- Large Bolt

- Large Nut

- 1/4in Rod

- Wire

- Electrical Tape

Important:

Building this handle can be done in different ways, depending on the tools and materials you have. You don’t need a large bolt, nut, and welder, as they require a lot of effort. A simpler alternative is to make a ring from some fencing wire, solder wire onto it, and screw it to a piece of wood. I decided to use the bolt, nut, and welder method because it was more convenient for me. This is how I did it:

Process:

- Strip about 8-12in of wire and wrap it around the bare metal on the bolt (This wire should come from the ground terminal of the capacitor in the buzzer box).

- Wrap The bolt and wire with electrical tape (This ensures the best possible contact between the bolt and the wire

- Take a sturdy wire (such as some let over 5mm rod) and bend it into a circle (You can choose how big or small)

- Weld your DIY ring to the nut

- Screw the nut/ring onto the bolt

This way you can buy multiple nuts and make each one have a different shape or size ring on it. You can quickly swap them out by unscrewing one nut and putting on a different nut.

Step 7: The Main Structure

Please Read:

As I mentioned in the title, I was in a time crunch with this project, so my dad did all the woodworking, so, unfortunately, I do not have any good photos or precise measurements. But I will explain to the best of my ability how this was built, and what the requirements are

Assembly of the Structure:

This is similar to the handle. It can be built in many different ways. It all depends on how you bend the wire, the total length of the wire, etc... I won't go into too much detail with this structure as again it very much depends on what you have in mind. I have included drawings that include the dimensions in inches.

Materials Used:

- 2x4in Wood

- 4x8ft sheet of Pressboard (I did not use the whole thing, just some cut-outs from it)

- Wood Screws

Step 8: Final Assembly

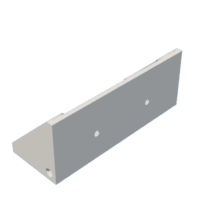

Bracket Assembly: (Follow the Order of the Images)

- Drill out the top hole of the four-hole bracket so that the 5mm rod spins nicely inside while maintaining full contact.

- Drill out a large hole in the wood where the fourth hole of the bracket is. This way you can bolt on a wire using an m4 bolt with a nut. (See the bottom part of Image 1) This allows the "Wacky Wire" to be grounded. This way when the handle makes contact with any part of the wire, current is allowed to pass and the buzzer goes off. (See the 1st and 2nd images)

- Screw the Four Hole Bracket into the proper place, Use only the two middle holes (So that it is in line with the "Wacky Wire", see the 1st, 2nd, and 3rd images)

Attach the Electronics Box:

- Cut out a section of the 2x4 to allow the Electronics box to sit flush (See image 4, See "Step 7 Video")

- Screw the Electronics box into the 2x4 using the pre-printed holes. Note: My screws are in a different place which required me to remove one of the rollers. In the updated design this is not the case. (See images 5-6)

Attach the Buzzer Box:

- Screw the Buzzer Box into the main structure using the pre-printed holes. Note: You want the user to be able to see this box since it lights up (See image 7)

Place the Wacky Wire and Handle in Place:

- Set the Main Roller (with the wire attached) on top of the Motor Assembly (See image 6)

- Insert the other end of the Wacky Wire into the bracket. Note: Be sure to have the handle on the inside of the wire to use. (See images 8-9)

Step 9: Final Product!

I hope you enjoyed this project!

Make this project how you want to do it. There is no right or wrong way to do it. Add little customizations and uniquely bend the wire, paint the wooden structure however you want. Build the wooden structure however you want. I have provided the basic blueprints, but you have the power to make this project into so many different and unique things. Have fun building this project.

If you have any questions, concerns, or helpful information feel free to leave a comment!

Runner Up in the

Arcade Student Design Challenge