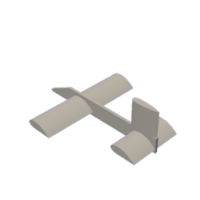

Introduction: 3D Printed Airfoiled Glider

Creating a 3D printed glider with an airfoil shape is an engaging project that combines design and aerodynamics. Begin by using 3D modeling software to craft the glider's fuselage, wings, tail, and any desired components. For the crucial airfoil-shaped wings, design the desired cross-section or choose from existing airfoil profiles, and extrude it along the wingspan. Incorporate control surfaces like ailerons and elevators for flight control. Once your design is complete, export it in a 3D printable format and select appropriate lightweight materials for 3D printing, such as PLA or PETG. After printing the components, assemble them securely, paying attention to balance and center of gravity. Test the glider in open areas, refining its performance as needed. Lastly, add personal touches and decorations to make your 3D printed glider uniquely yours.

Supplies

- 3D Printer

- PLA Filament

- Build Plate

- Build Plate Adhesion Tools

- Spatula or Removal Tool

- Filament Storage Solutions

- Nozzle Cleaning Tools

- Filament Dryer

- Calipers

- Bed Leveling Tools

Step 1: 3D Printed Glide

Creating a 3D printed glider is fun and educational. Use 3D software to design the fuselage, wings, and tail. Craft airfoil-shaped wings and add control surfaces. 3D print it, balance, test, and personalize it for unique flights.