Introduction: 3D Printed Smart Watch Dock

I was tired of leaving my watch charging with a messy cord attached on my desk, so I decided to design this simple dock for it. The cradle is made of wood fiber PLA 3D printing filament, and the insert for the charging pad is made of flexible PLA filament. Since the inset is removable, this design could work with a variety of other smart watches.

Step 1: Design + 3D Modeling

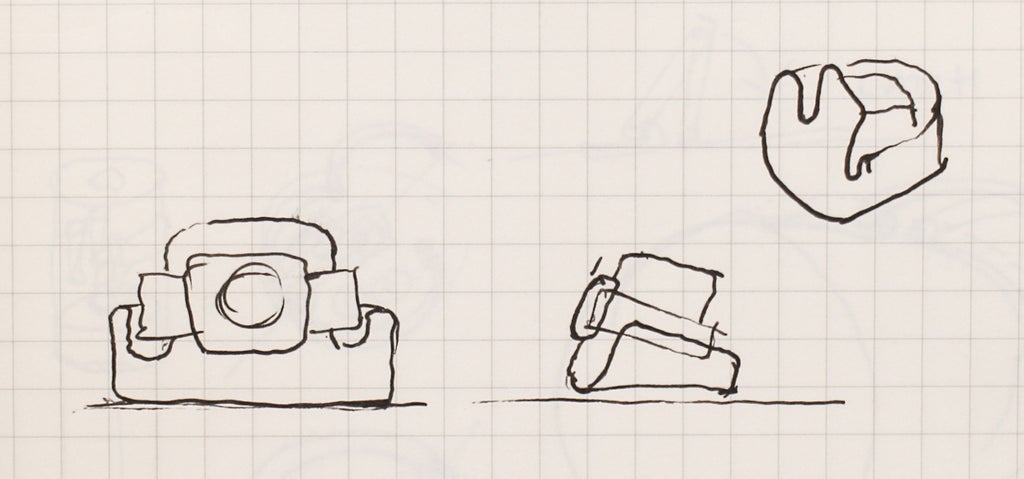

The design is simple. Before I got started, I quickly sketched an idea of the shape of the dock. The Apple Watch becomes an alarm clock when it's charging and oriented on its side, so I designed the dock to be kind of a cowboy hat shape- there's a bubble in the middle that holds the charging pad with a raised brim around it to keep the watch band in place.

I used Fusion 360 for the 3D modeling. I use it pretty much exclusively because it's free, easy to learn, stable, and great for 3D printing. The youtube video in this step is a 4X speed capture of the modeling process. The whole project took 23 minutes to model.

The insert that holds the charging pad is a separate piece because I wanted to be able to swap it our for another charger if I ever replace the watch with a different model.

The STL files are here for download, and here's a link to the Fusion 360 file: http://a360.co/1Y85Lue

Fusion 360 is free for students and hobbyists, and there's a ton of educational support on it. If you want to learn to 3D model the kind of work I do, I think this is the best choice on the market. Click the links below to sign up:

Step 2: 3D Printing

TOOLS + MATERIALS

I use a Prusa I3Mk3S for just about everything. It's the best bang for your buck, in my opinion- very well made, 3D printable replacement parts, accurate and reliable.

I used MG Chemicals Wood 3D Printer Filament for the cradle because I love the quality of the finish. It feels just a bit classier than PLA plastic and behaves very well on my printer. It responds well to sanding and wood stains, and it actually smells like wood while it's printing!

For the flexible insert part, I used Matter Hackers White Soft PLA. It's flexible, but not elastic. This means it keeps its shape but won't break when you force it into a tight space, and will allow you to push it into the cavity at a weird angle.

SETTINGS

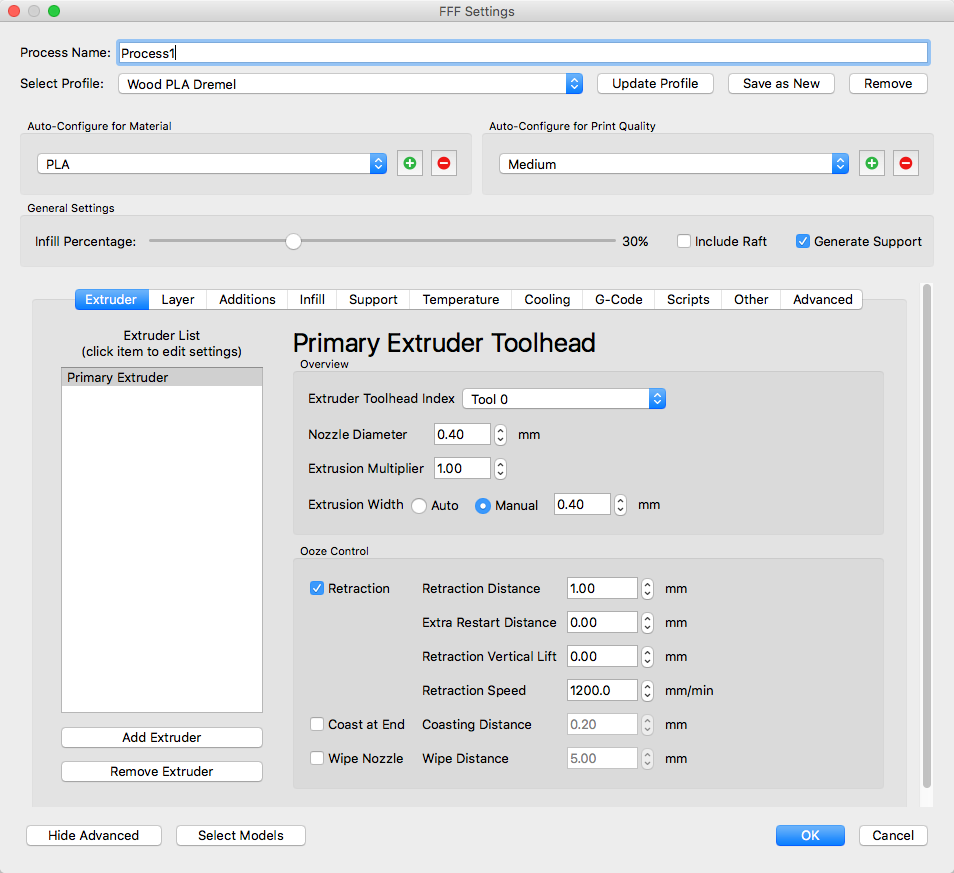

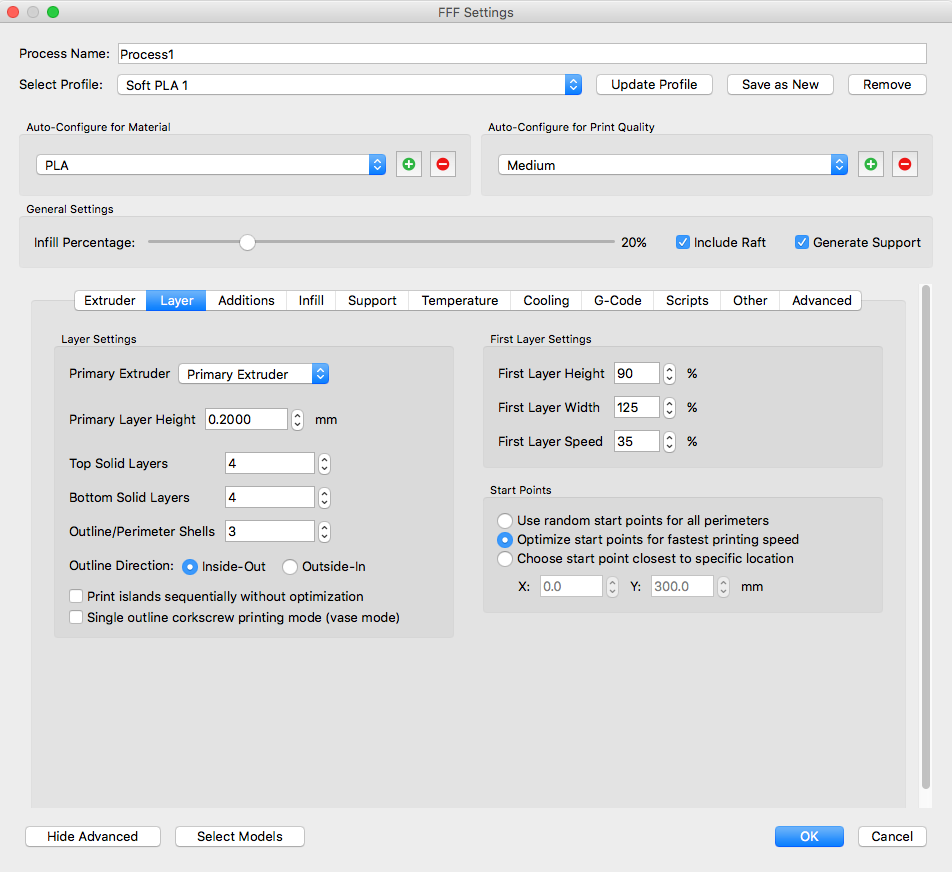

I use Simplify 3D for all my slicing because it gives me a high level of control, has excellent support structures, and yields good results just about every time.

Wood Filament Settings

Soft PLA Settings: Do no preheat nozzle!

Step 3: Assembly

I designed the piece so that the flexible insert would fit snugly in the cradle with the charging pad inserted. The whole piece came together quickly and works great!

Do you have a different brand of smart watch? Ping me and maybe we can figure out an insert for it.