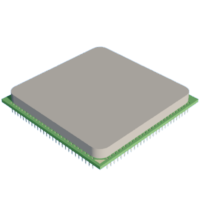

Introduction: Giant CPU

When I built my very first desktop computer, I was on a very tight budget and at the time all I could afford as a CPU was the AMD Athlon 64 x2 6000+.

I wanted to make something special in memory of the said machine, here we are, more than a decade later.

I decided to make giant version of the CPU that served me so well.

Supplies

Some of the materials I used were scraps I had laying around, I only had to buy one of the wood panels and some nails to complete what I already had.

- Wood panel 6mm (±4€)

I used MDF as I think it looks better than real wood when painted and because it's cheap :)

The smallest panel I could find was 810*405 mm thus I ended up paying 4€ but really it could be less as I ended up using less than 250*250mm for my CPU

- Wood panel 18mm (±4€)

I used pine wood as I had a big piece remaining from another project but any wood would work, idealy something homogeneous and smooth, I ended up using a bit less than 235*235mm for my CPU

- Golden nails 1.6*20mm (±7€)

You can find these at your local hardware store, they are sometimes called brass nails and sometimes golden nails .-.

I used 940 nails but in the bags I purchased some nails were 5mm too long and some were 5mm too short, go figure...

I used a total of 3 bags of 125g for 940 nails and I still had about 30 to spare

- Paint

Paint is very expensive when you need specific shades

I do not really know the cost of the specific paint I used as I already had the needed shades

I used MTN hardcore spray paint, "Silver Chrome" for the Lid, "Lutecia Green" for the PCB, "Element green" for the sides of the PCB, and "Gold" for the arrows on the PCB

- Varnish

Because I was using MTN spray paint, I chose to use their "Acrylic Varnish" to ensure chemical compatibility with the paint

Keep in mind that you should always make a test piece for any paint/varnish compatibility as this could make the difference between ruining your paint job and finishing your piece

- Wood filler

Could be substituded by plaster perhaps ?

- Wood Glue

Hot glue should be fine

Step 1: Conception

Finding the name of the socket used by your CPU

A quick search for your CPU's make and model on the internet will tell you the name of the socket it uses.

I chose to work with the AMD Athlon 64 x2 6000+, this specific CPU uses the AM2 socket, take note of that information as we'll need it in the next step.

Finding the technical information about your CPU socket

Same as in the previous step, all you need is to search the internet for "Socket AM2 Design Specification" obviously replacing Socket AM2 with your socket's name.

Usually you'll find a PDF file hosted on the website of the manufacturer, in my case, the said file can be found here.

Gathering useful info

We've found this great documentation with plenty of information, it's time to extract the data we're going to use !

We need the dimensions for our CPU, in my case I could find the info at page 9 of the previously recovered document. On the same page I also found the number of pins of my CPU (940 pins) as well as the implantation of these pins.

Defining the scale

I chose an arbitrary scale of 6:1.

I think for such projects, what matters is how you intend to use the finished piece and the space you are willing to allocate to it.

In this project there was another consideration, I could not find nails for all sizes thus I could not scale properly the pins of the CPU.

Step 2: Modeling

Get busy modeling !

I used Fusion 360 to create my model since I am familiar with this tool, but at the end of the day it all depends on what you have on hand, as much in terms of software as in terms of hardware and machinery. Don't go make a 3D model if you know how to work on paper and you're going to make the piece using hand tools anyways.

I followed the plans from the technical document and made sure to scale all dimensions accordingly.

Scaling up really means multiplying the original dimensions by the scale factor, here 6.

The complex part

I am no graphic designer, I can barely use paint, but now somehow I had to make the decal for the CPU Lid.

I first tried using Paint Dot Net, a free image manipulation software for Windows. I wanted to extract the text and shapes from a picture of the CPU I found on the internet.

Spoiler alert: It didn't work, the image had multiple shades on the lid making batch treatement unfeasible.

I ended up redrawing the whole CPU lid in Paint Dot Net by using a font that more or less matched the one AMD used on the CPU. The font is named RoadGeek 2005 Series E and can be found here.

Once the drawing was done, I needed to make a vector drawing out of it for laser engraving, for that I used Inkscape.

I followed this tutorial to learn how to convert my PNG image to a SVG path.

Joined to this step are my STEP files as well as my SVG file.

Step 3: Let's Make Some Wood Chips !

Carvin'

Using the magic machine, AKA the CNC, I made the cut :p

First piece was the PCB, I used the 6mm MDF wood, I first milled the hole for the nail heads, then I milled the hole for the nail itself, and finaly I milled the contour.

Second piece was the Lid, I used the 18mm wood, here the only thing to mill was the contour.

Engraving the lid

I made some tests and found out that painting after engraving gave a better effect than the other way round.

I subsequently engraved the Lid using my laser cutter.

Step 4: Painting !

To aid with painting the golden arrow on the pcb I laser cut some masking tape ans used it as a stencil.

- Paint the Lid

- Paint the PCB (pin side only)

- Paint the golden arrow using the laser cut stencil (pin side only)

- Varnish

Step 5: Pin Stuffing ?

This was an incredibly long process (>2h), stuffing 940pins into the holes is no joke I'll tell you that !

Step 6: Surfacing the PCB

If you've followed along so far, you should have a non painted side of the PCB, the Lid side.

This side also has the nail heads and holes in the wood.

I used wood filler to fill the holes and sanded after it had dried, only then did I apply the same paint job as the pin side.

Once this part was dried, I painted the sides of the PCB and applied a coat of varnish after using masking tape to mask the pins.

Step 7: Assembly

I applied a decent coat of wood glue to the back side of the Lid, then I glued it to the top of the PCB.

I know that this is a bit anticlimactic but that's really all there is to it ...

Step 8: Optional

A friend of mine was very disapointed to see that the trademark "AMD ugly silicone seam" was missing.

You could use some silicone caulk to add this "feature" if that's your thing.

Participated in the

Go Big Challenge